Mounting ship of offshore wind turbine and construction method thereof

A technology for offshore wind turbines and installation ships, applied in the engineering field, can solve the problems of complex construction, high installation cost, and difficulty, and achieve the effect of reducing construction difficulty, easy construction, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

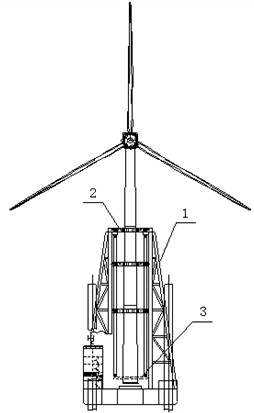

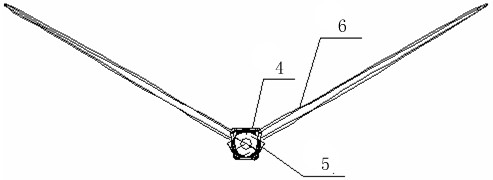

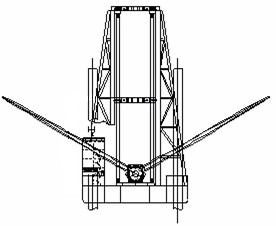

[0033] As shown in the figure, the installation frame system includes a lifting device and a mounting frame 1 installed on the left and right sides of the bow. The lifting device is mainly composed of a motor, a pulley block, a wire rope, etc., and can vertically lift the holding platform 3 and the complete fan unit. The lifting height is 60 meters and the lifting weight is 900 tons. The holding platform 3 is an open and close platform. When the wind turbine is installed, it can hold the wind turbine tower tightly and lift it. It can bear the weight of the whole wind turbine and has a lifting capacity of about 800 tons. 8 guide positioning wheels are arranged around the tight platform 3 to prevent the platform from moving along the length and width of the ship. The centralizing device 2 adopts the opening and closing type, which protects the wind turbine tower in the working state, can bear the eccentric load and wind load when the wind turbine is lifted, and prevents the wind...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap