Synchronous driving multipoint suspension vertical lifting platform

A lifting platform, synchronous drive technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of poor running stability of the drive system, accelerated wear of the drive system, and reduced transmission efficiency, so as to eliminate adverse effects, achieve smooth operation, and avoid running Unsteady effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

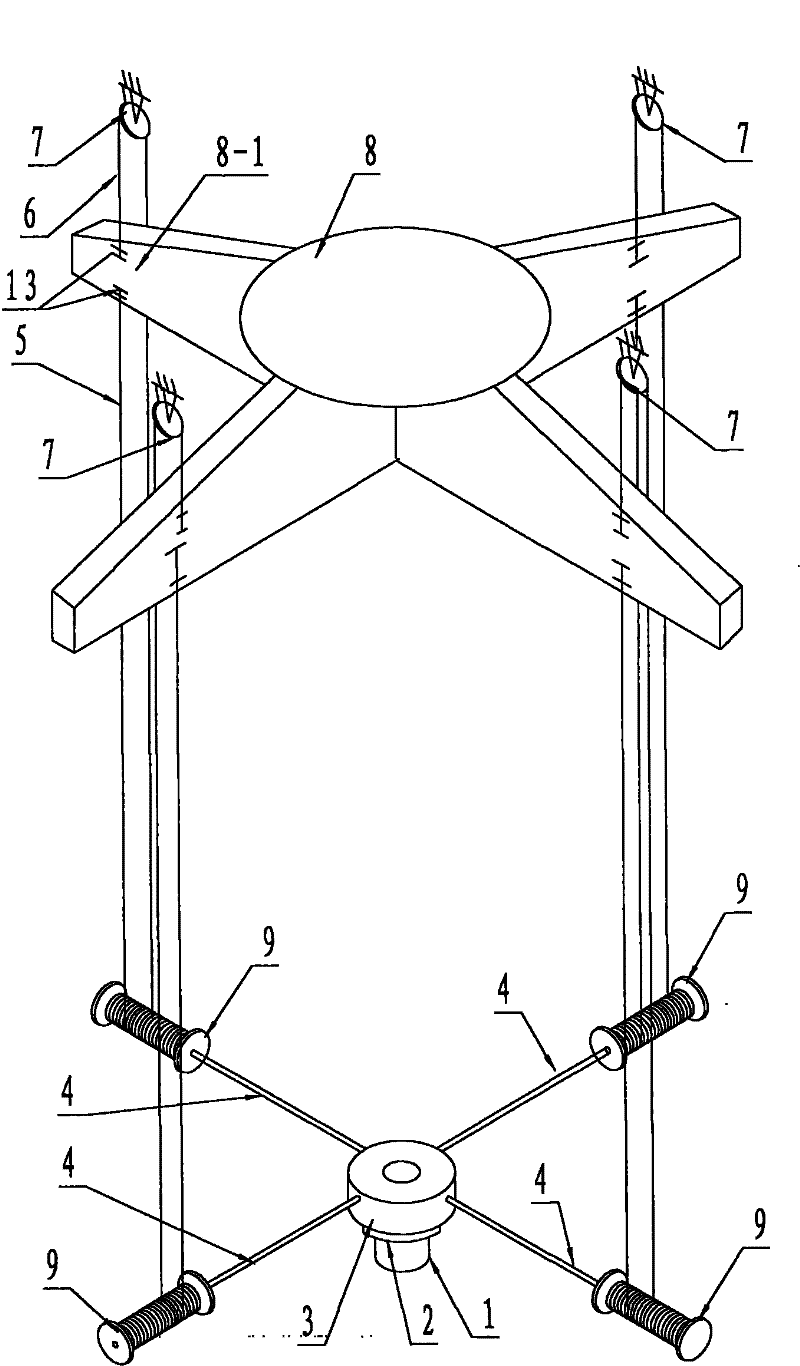

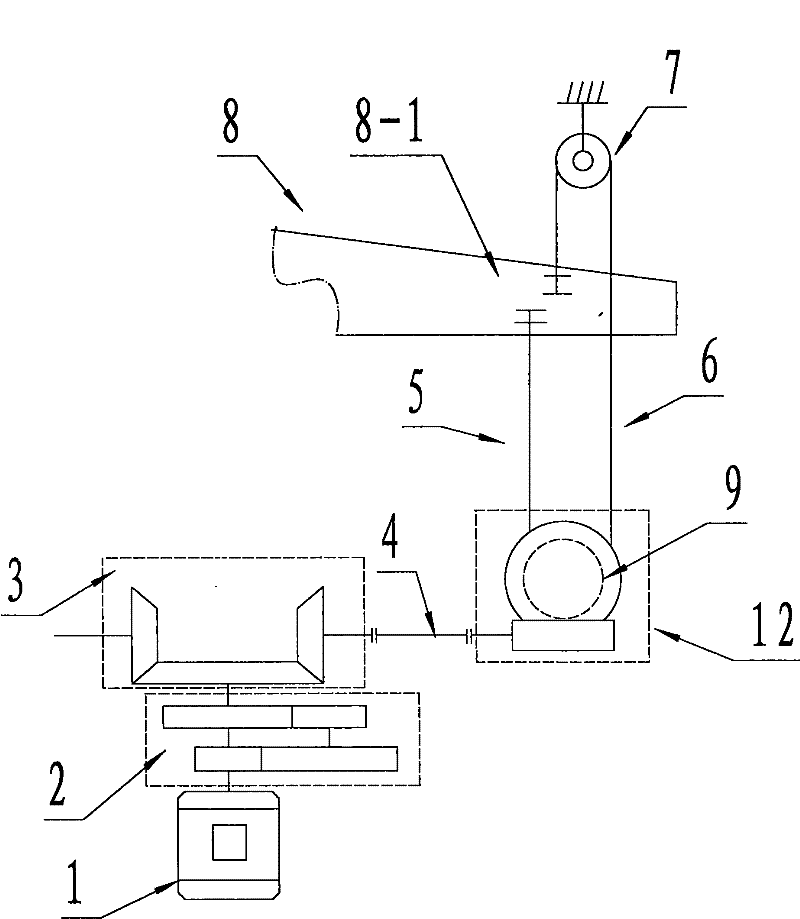

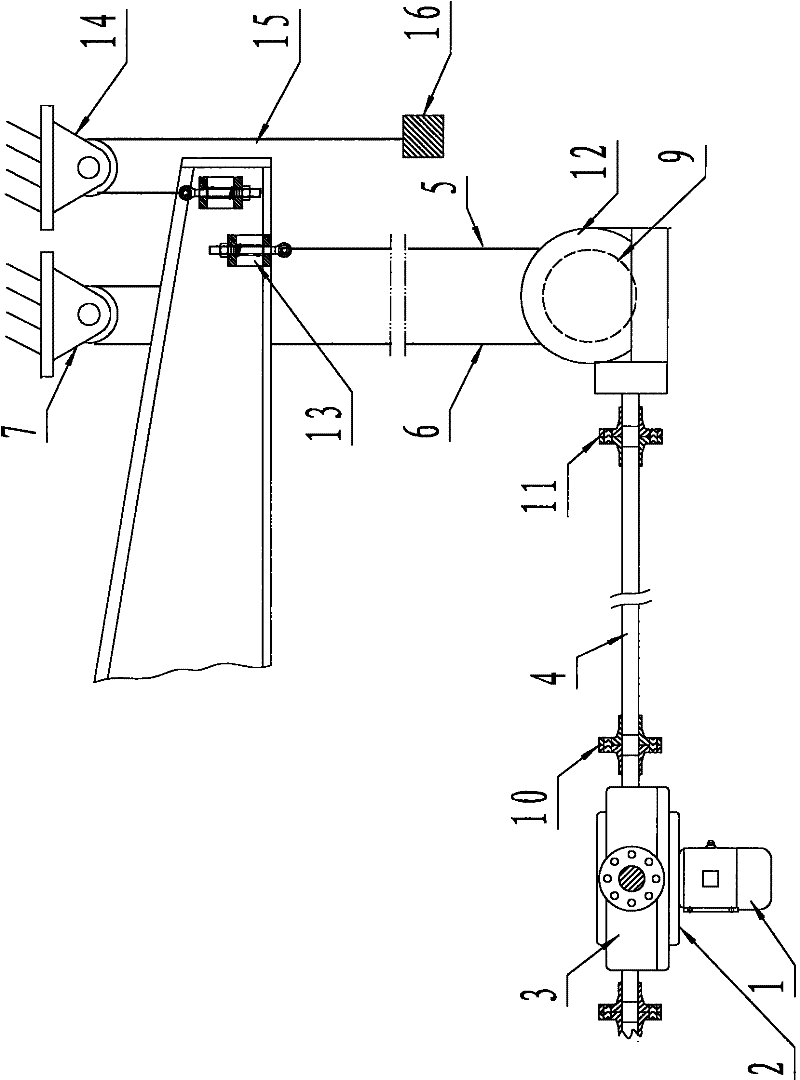

[0014] see figure 1 , Embodiment 1 of the present invention is the basic structure of the lifting platform, which includes a lifting platform body 8, a power unit, a power synchronous distributor 3, a roller 9 and a wire rope. The power device consists of a motor 1 and a reducer 2. The motor power is decelerated by the reducer and then transmitted to the power synchronous distributor. The power synchronous distributor transmits the power synchronously to the 4 transmission shafts 4, and each transmission shaft drives each roller 9 respectively. . Two wire ropes 5 and 6 are wound on each roller 9 in two opposite directions, and one end of the two wire ropes is respectively fixed to the roller, and the other end of the first wire rope 5 is connected to the body of the lifting platform through the wire rope buffer elastic regulator 13 One of the suspension points 8-1 is fixedly connected; the other end of the second steel wire rope 6 passes through the fixed pulley 7 above the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com