Oil sealing device on end part of steam turbine shaft

A steam turbine and shaft end technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve the problems that the oil seal at both ends of the steam turbine shaft cannot meet the market demand, and the safety and stability of the coupling affect the work. Convenience, prevent oil leakage, and enhance the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

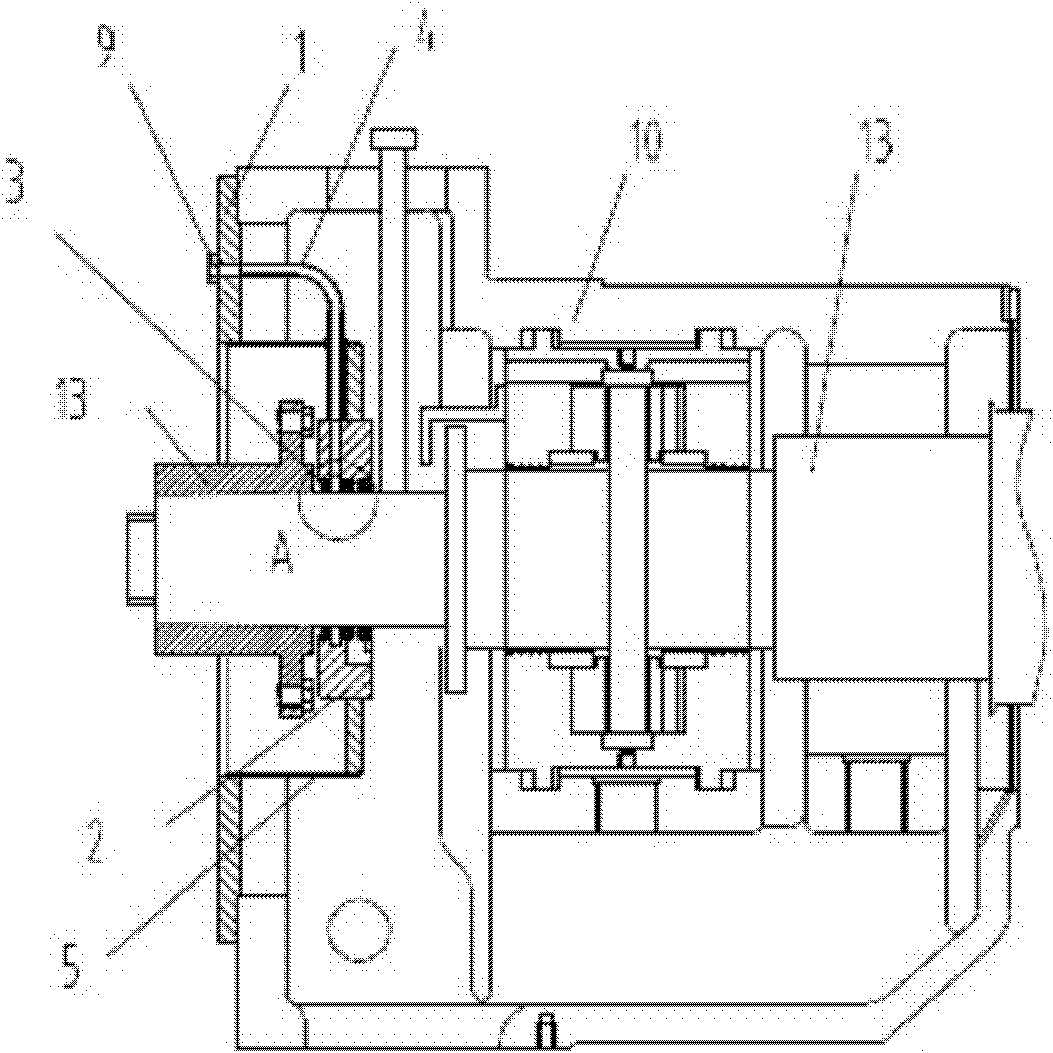

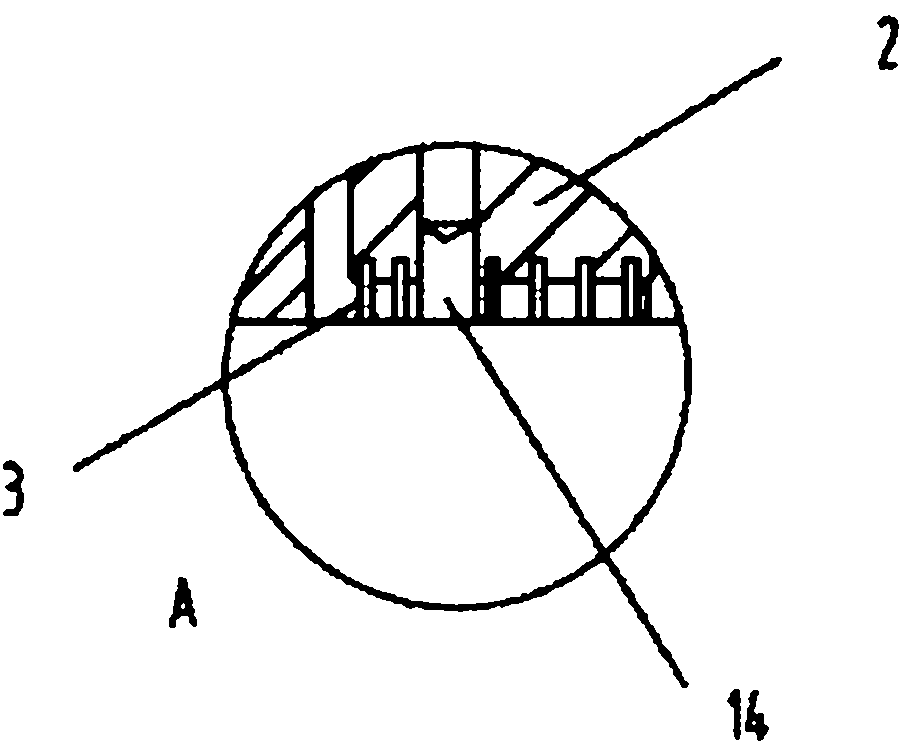

[0017] Such as figure 1 As shown, the oil sealing device at the end of the steam turbine shaft described in this embodiment is used for oil sealing the front end of the steam turbine shaft. The outer seal ring 1 on the seat 10 and the inner seal ring 2 sleeved on the steam turbine shaft 12 are composed of the outer seal ring 1 and the inner seal ring 2 which are distributed in steps and connected by a seal plate 5 therebetween, and the inner seal ring 2 of the inner seal ring 2 There are sealing teeth 3 on the ring mouth. In order to make the sealing ring fit into the end of the steam turbine shaft 12 and the front support 10 of the steam turbine accurately after the coupling 13 is installed, the sealing ring is formed by connecting the upper and lower parts, and The connection surface is the mid-section surface of the sealing ring, and the upper and lower parts are connected together by mid-section bolts 8 . Such as image 3 As shown, the oil sealing device also includes an...

Embodiment 2

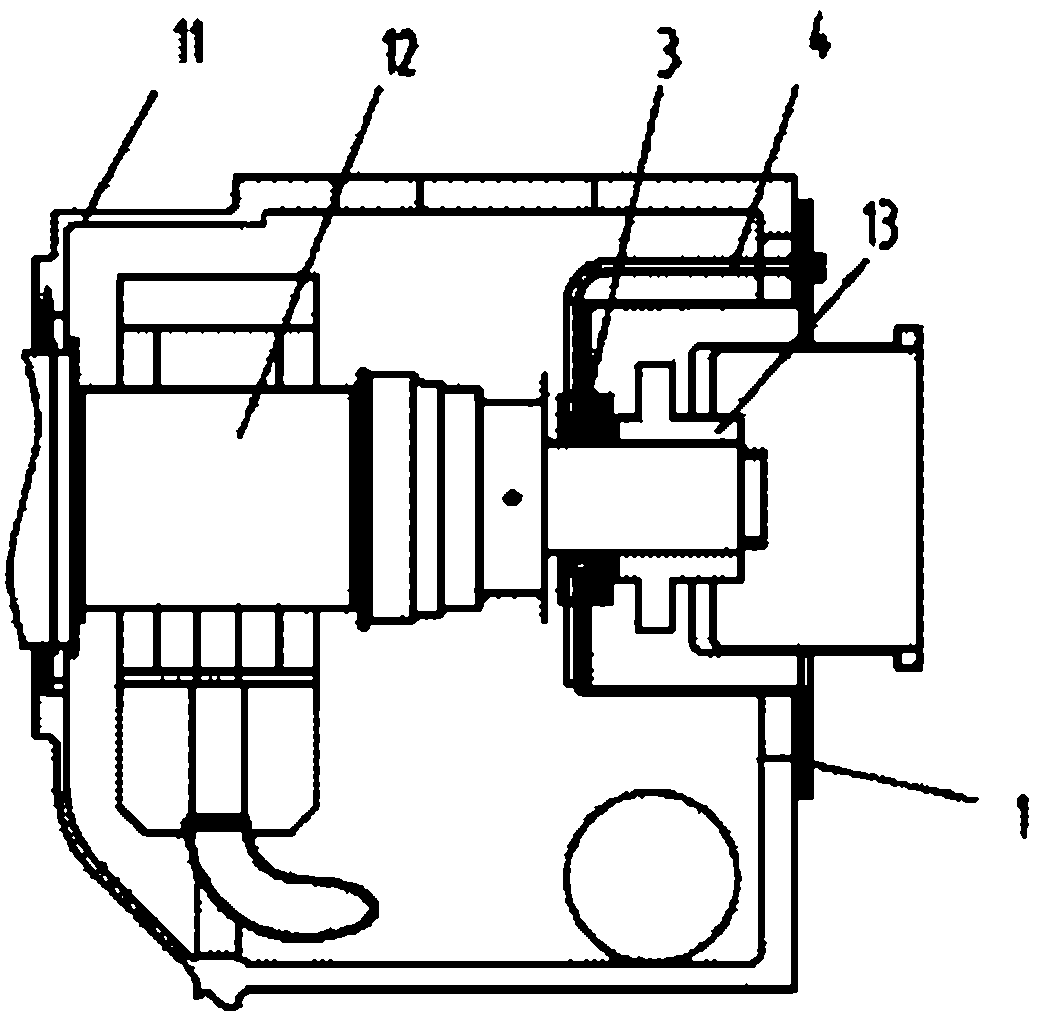

[0020] Such as figure 2 As shown, the oil sealing device at the end of the steam turbine shaft described in this embodiment is used for oil sealing the rear end of the steam turbine shaft. The outer seal ring 1 on the support 11 and the inner seal ring 2 sleeved on the steam turbine shaft 12 are composed. The outer seal ring 1 and the inner seal ring 2 are distributed in steps and connected by a seal plate 5. The inner seal ring 2 The inner ring mouth is provided with sealing teeth 3, and the distance between the sealing teeth 3 and the turbine shaft 12 is selected within the range of 0-0.015 μm, here is 0.010 μm; in order to make the sealing ring accurate after the coupling 13 is installed Install the steam turbine shaft 12 and the end of the steam turbine support without error. The sealing ring is formed by connecting the upper and lower parts, and the connecting surface is the middle parting surface of the sealing ring, and the ground bolts connect the upper and lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com