Fault-tolerance permanent magnet linear motor

A permanent magnet linear motor, fault-tolerant technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem of inability to meet high requirements for high reliability and continuous operation, low power factor, power density and efficiency, and influence The non-faulty phase of the motor works normally, and achieves the effect of strong operation ability with faults, good heat dissipation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

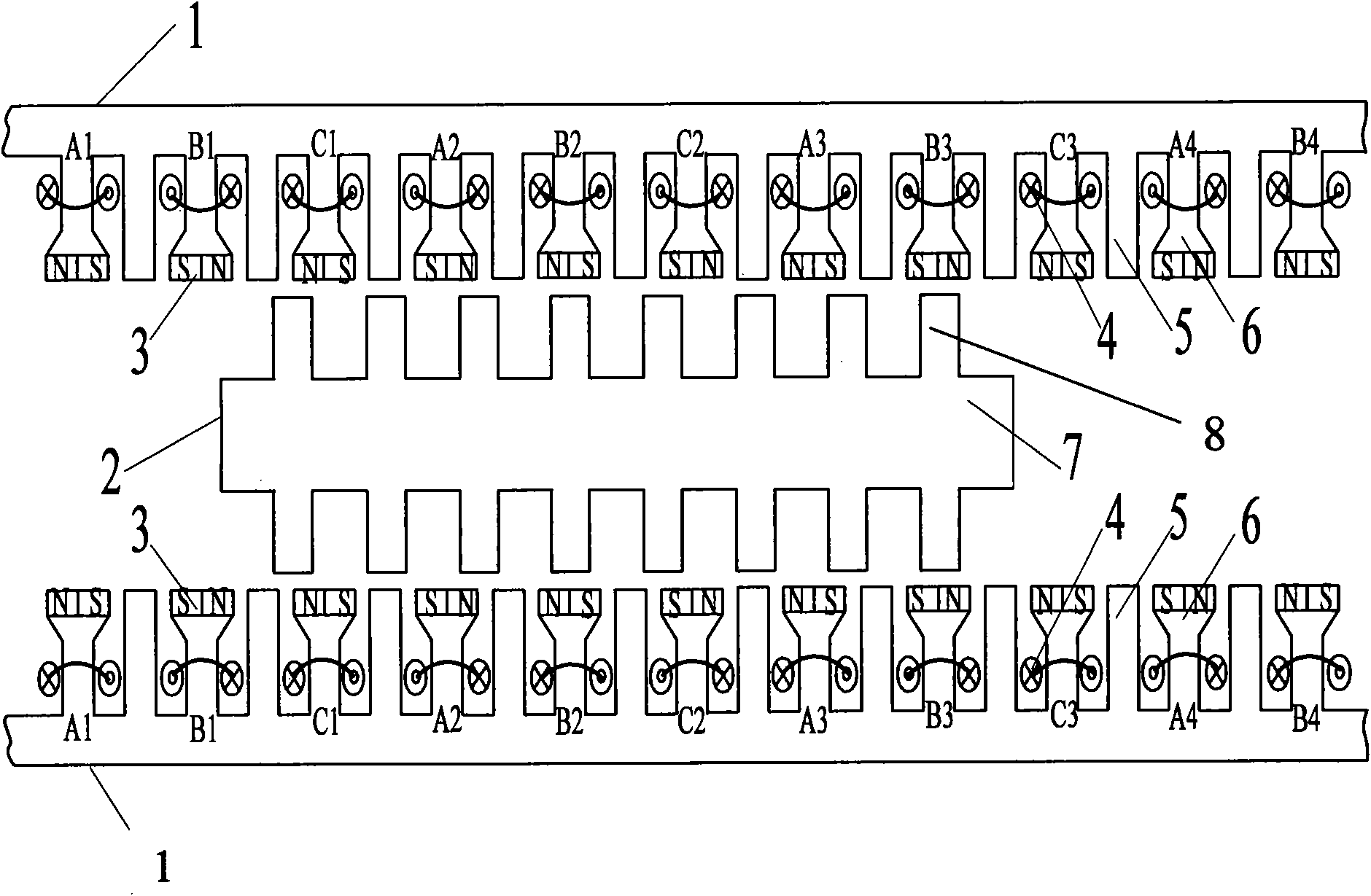

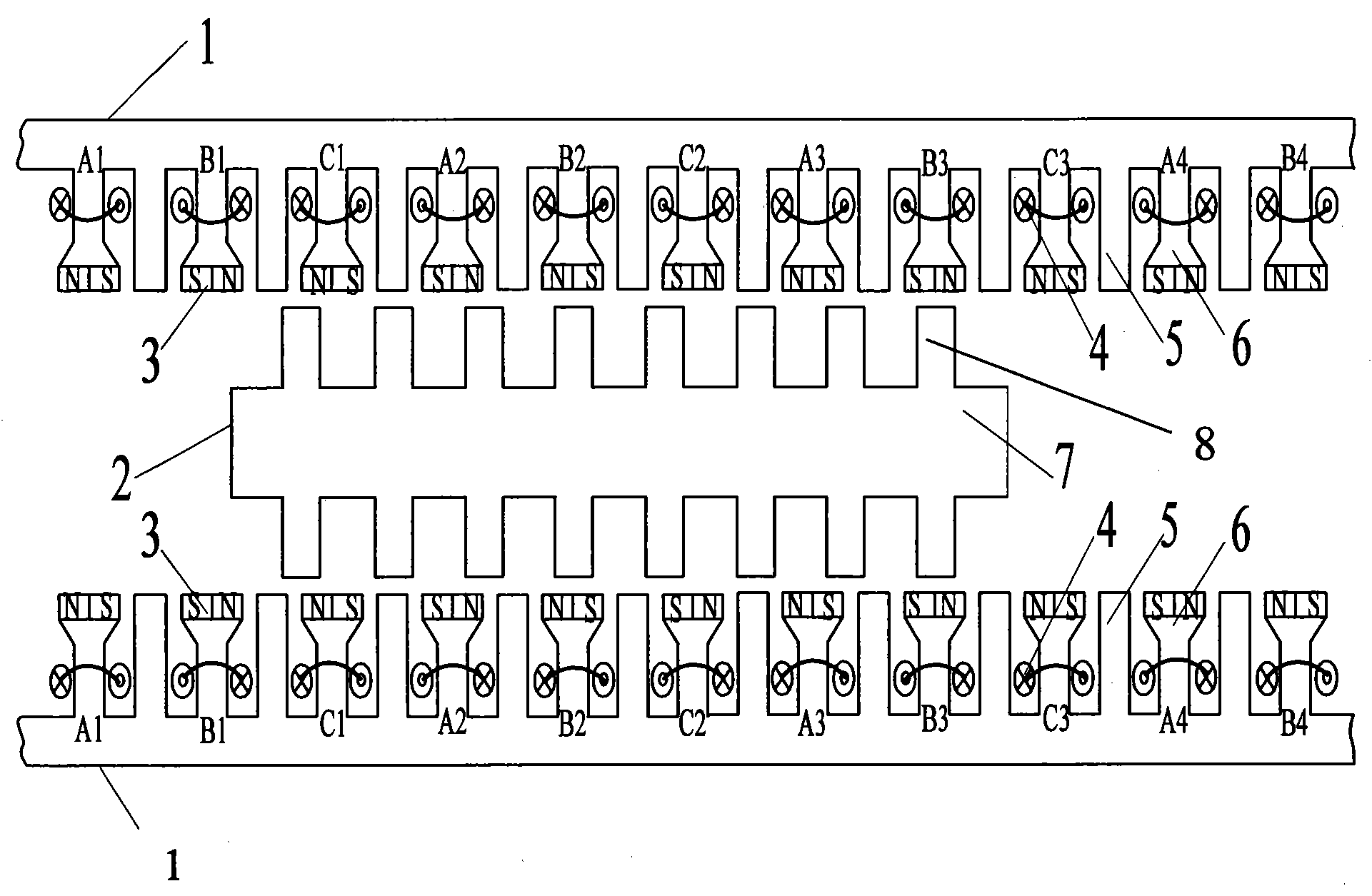

[0018] Such as figure 1 As shown, the present invention consists of a stator 1, a mover 2 and a permanent magnet 3 fixed on the stator 1, an armature winding 4, an isolated tooth 5, an armature tooth 6 and an iron core 7 on the mover 2. The length of the mover 2 is smaller than that of the stator 1 . A plurality of armature teeth 6 are evenly spaced on the stator 1, and the armature teeth 6 are laminated with sufficient punches. A spacer tooth 5 is set between every two adjacent armature teeth 6, and two pieces of opposite polarity The permanent magnet 3 is fixed on the end of the armature tooth 6 by surface mounting, so that the equivalent air gap length at the end of the armature tooth 6 increases. The height of the spacer teeth 5 is greater than the height of the armature teeth 6 on which the permanent magnets 3 are attached. The armature winding 4 is wound on the armature tooth 6, that is, the stator 1 without winding is the isolated tooth 5, the armature winding 4 adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com