Mounting table structure, and treating apparatus

A processing device and a mounting table technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of consumption of purge gas, damage of the mounting table 2, damage of thermal stress, etc., so as to suppress supply and prevent damage. , The effect of preventing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, a preferred embodiment of the mounting table structure and processing device of the present invention will be described in detail based on the drawings.

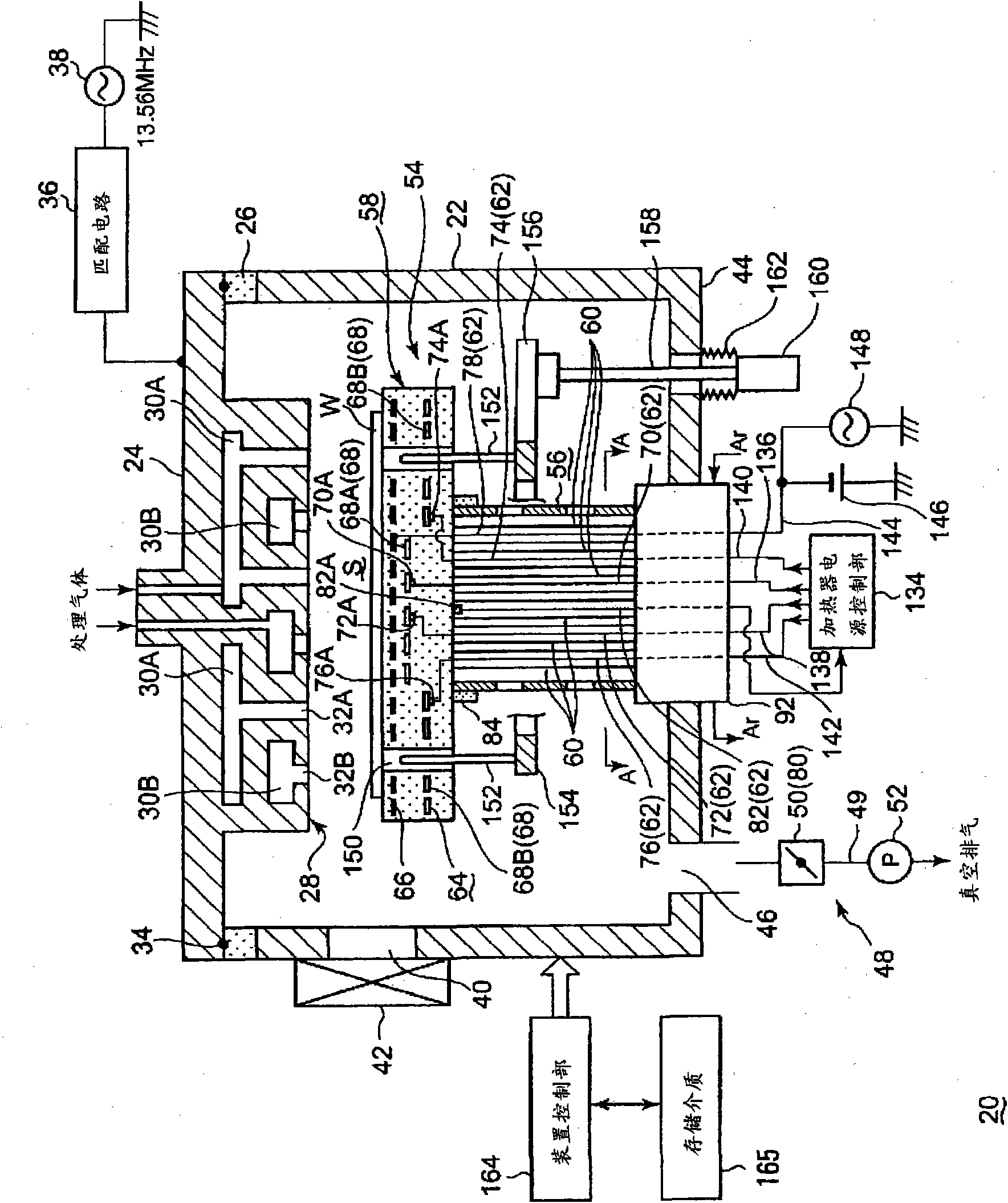

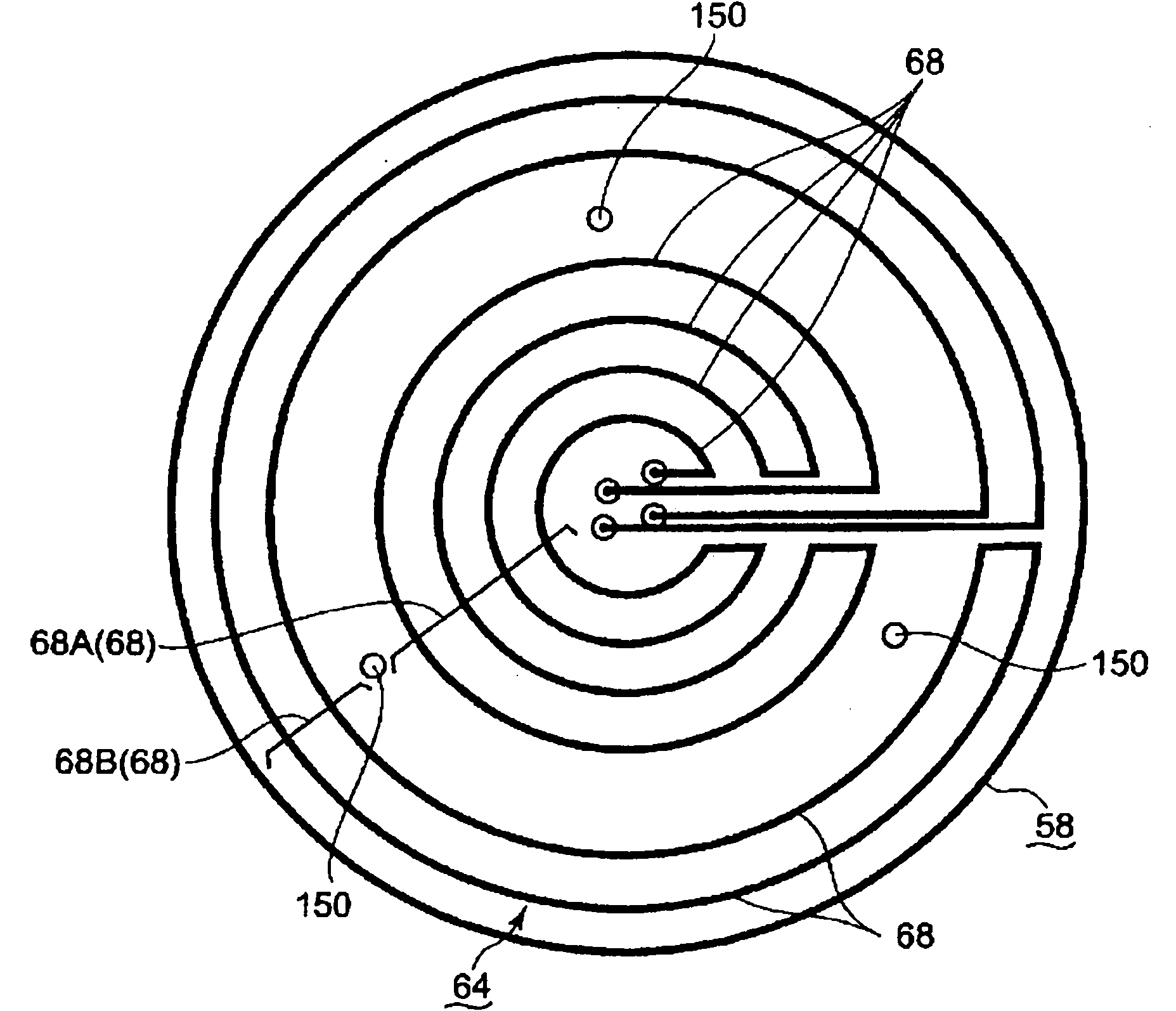

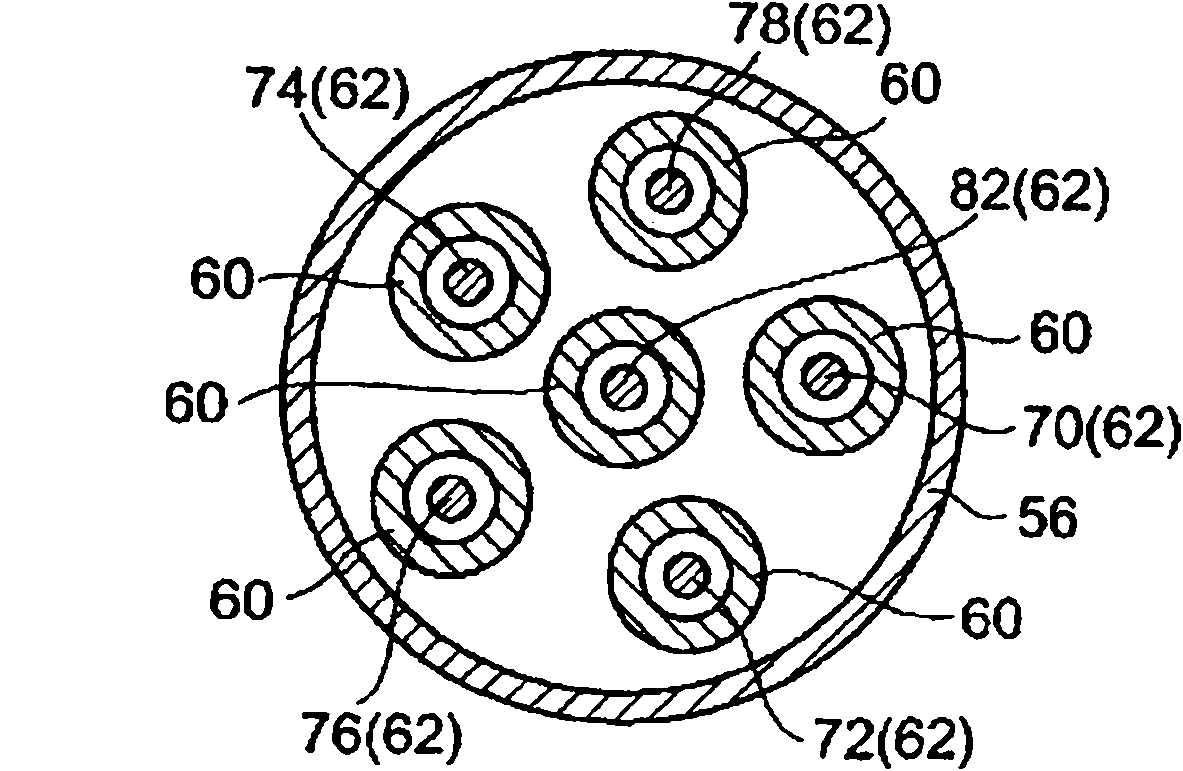

[0052] figure 1 It is a cross-sectional configuration diagram showing a processing device having a stage structure according to the present invention, figure 2 It is a plan view showing an example of a heating mechanism provided on a mounting table, image 3 is along figure 1 The cross-sectional view of the arrow direction of the A-A line, Figure 4 is will be with figure 1 The part corresponding to the inner area of the heating mechanism of the stage structure is representatively taken out and shown in a partially enlarged cross-sectional view, Figure 5 is for illustration Figure 4 An explanatory diagram of the assembled state of the stage structure in . Here, a case where a film formation process is performed using plasma will be described as an example.

[0053] As shown in the figure, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com