Clamping body for tool box

A technology of tool boxes and clamping bodies, applied in the field of tool boxes, can solve problems such as difficulty in inserting and pulling out tools, difficulty in determining the tightness of the socket and tool handle, etc., to reduce friction, reduce contact area, and reduce force. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

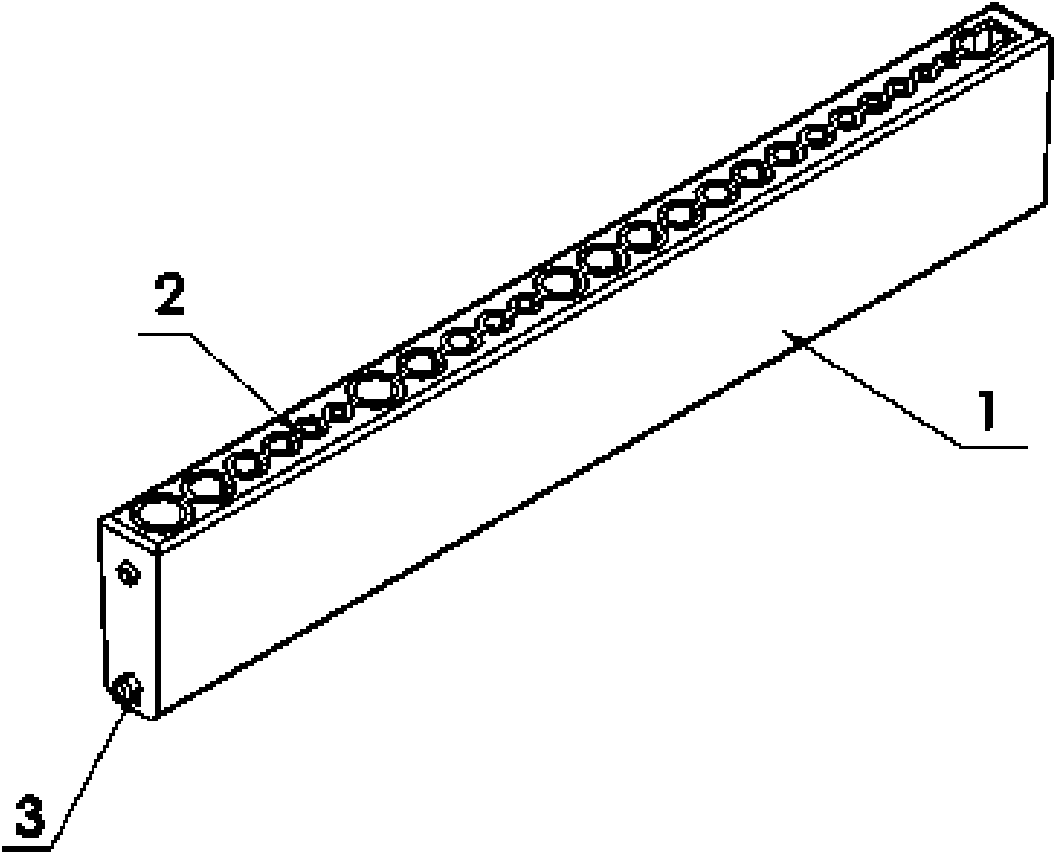

[0024] Example: such as figure 1 As shown, a holding body for a tool box includes a housing 1 , a holding body 2 fixed in the housing and provided with an insertion hole, and pivots 3 are provided at both ends of the housing.

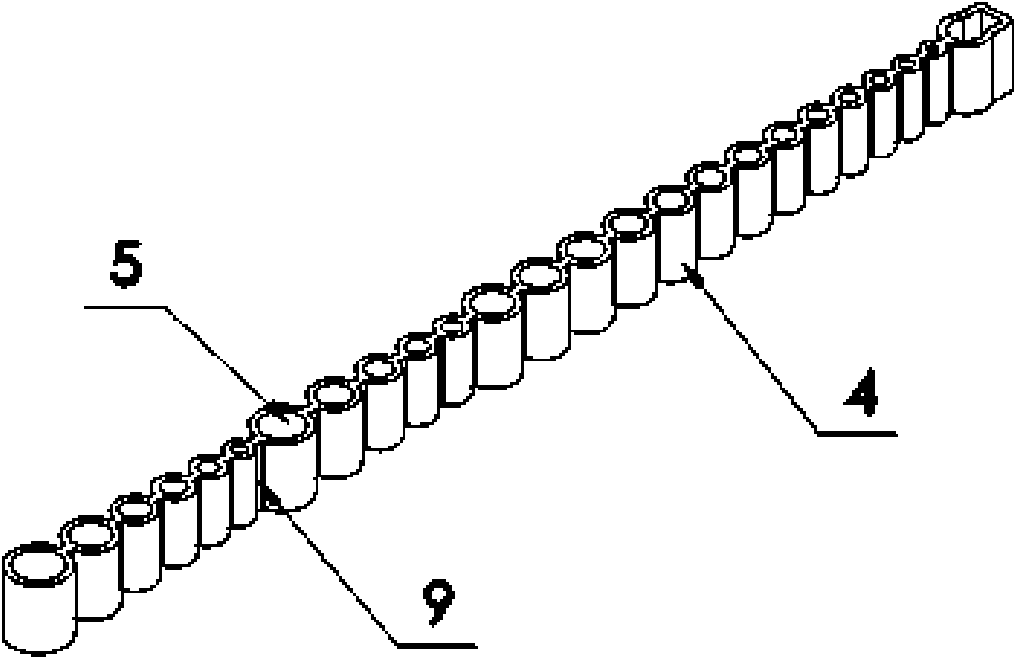

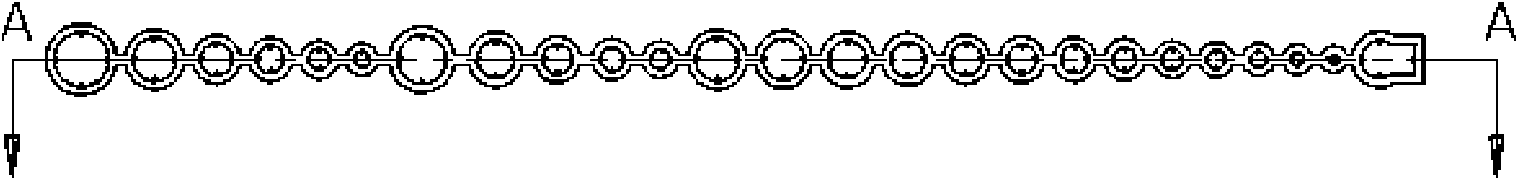

[0025] The holding body 2 is composed of 25 cylinders and 4 conjoined bodies, the cylinders are provided with jacks 5, and the cylinders are connected with ribs 9, such as figure 2 shown.

[0026] The lower end of the jack 5 is provided with uniformly distributed four ribs 6, the ribs are in the shape of a triangular pyramid, the height of the triangular pyramid is 15mm, and the length of the triangle at the bottom of the triangular pyramid is 3mm, as Figure 4 shown.

[0027] like Figure 5 As shown, the housing 1 is a cuboid with an opening 7 on one side, and the opening is used to accommodate the elastic holding body 2. The opening of the housing is provided with an inwardly folded edge 8, which is pressed into the housing by elastic deformation....

Embodiment 2

[0029] Embodiment 2: as Figure 7 As shown, the holding body is a cuboid structure 11, and the side walls of the socket 5 provided thereon are evenly provided with four ribs in the shape of a trapezoidal quadrangular prism, and the upper ends of the ribs are arranged toward the center of the jack. There is an inclined plane, and twenty-four round holes 5 and a special-shaped jack 9 are set on the cuboid 11.

[0030] In the present invention, ribs are arranged in the socket of the holding body to eliminate the closed air film inside the socket, avoid the negative pressure of the air film when the tool is pulled out, reduce the contact area between the tool and the wall of the socket, reduce friction, and avoid The soft material on the wall of the socket rebounds and tightly wraps the tool handle, making it difficult to pull out the tool due to the large static friction force; because the force of inserting or pulling the tool is greatly reduced, the relevant parts, especially t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com