Movable-molding cavity injection-pressing moulding method of plastic microfluidic chip

A technology of microfluidic chip and molding method, applied in the direction of coating, etc., can solve the problem of not copying the right angle of the root of the mold cavity insert, and achieve the effect of avoiding spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

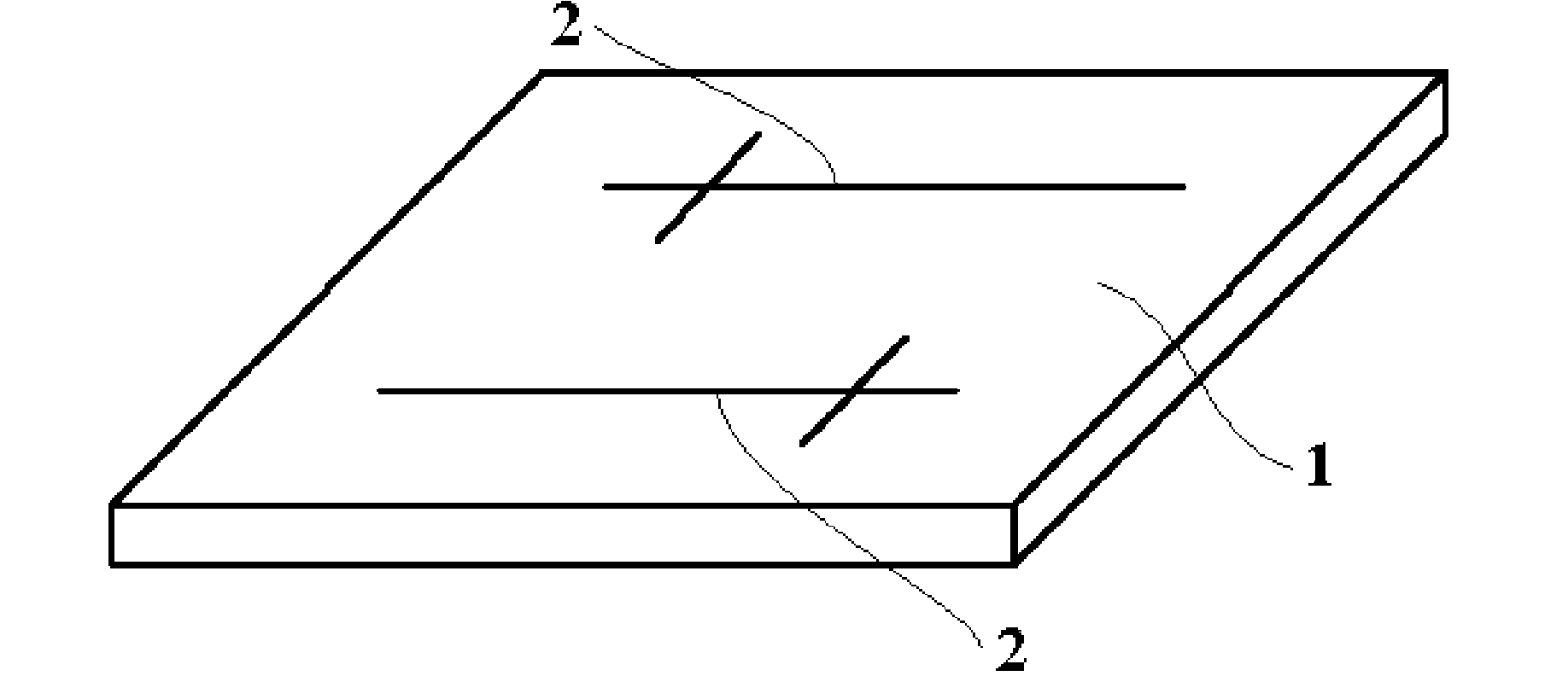

[0021] Such as figure 1 As shown, the plastic microfluidic chip 1 to be molded has microgrooves 2 . The dimensions of the plastic microfluidic chip 1 are: length 40mm-100mm, width 25mm-100mm, thickness 1mm-2mm. The microgroove 2 can be as figure 1 A cruciform arrangement is shown, but a serpentine or other arrangement is also possible. The molding material of the plastic microfluidic chip 1 can be polymethyl methacrylate (PMMA) or polycarbonate (PC).

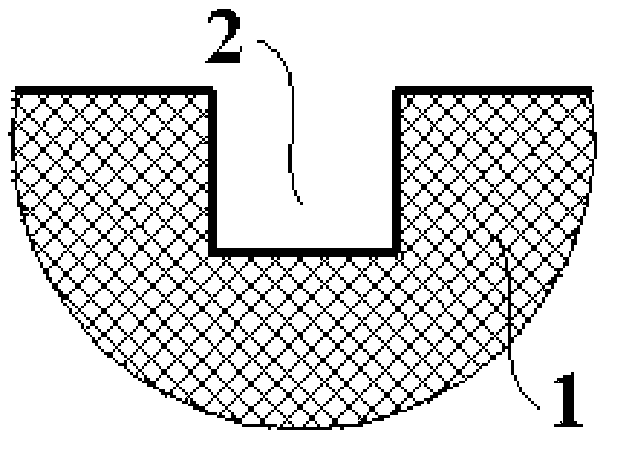

[0022] Such as figure 2 As shown, the cross-sectional shape of the microgroove 2 on the plastic microfluidic chip 1 is required to be rectangular, trapezoidal or triangular. The cross-sectional size of the micro-groove 2 is: a width of 30 microns to 100 microns, and a height of 30 microns to 100 microns.

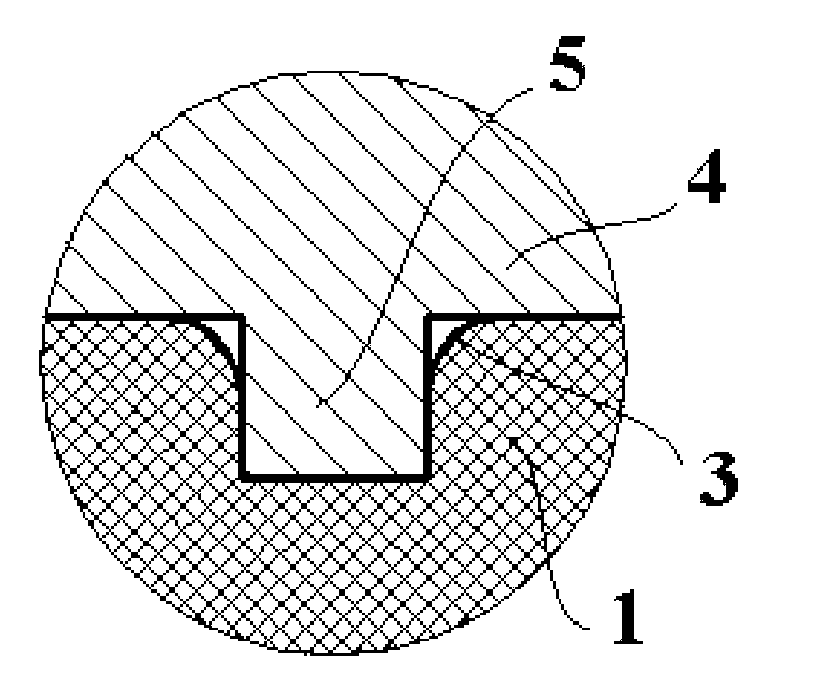

[0023] Such as image 3 As shown, the microgrooves 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com