Micro inertial sensor with transversely movable electrodes embedded and manufacturing method thereof

A technology of moving electrodes and lateral movement, which is applied to the components of the TV system, the photoplate process of the pattern surface, piezoelectric/electrostrictive/magnetostrictive devices, etc., and can solve the problem of increasing the mass of the sensor vibrator and the distance between the capacitor plates Reduce and other problems, to achieve the effect of mechanical noise improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is by no means limited to the described embodiments.

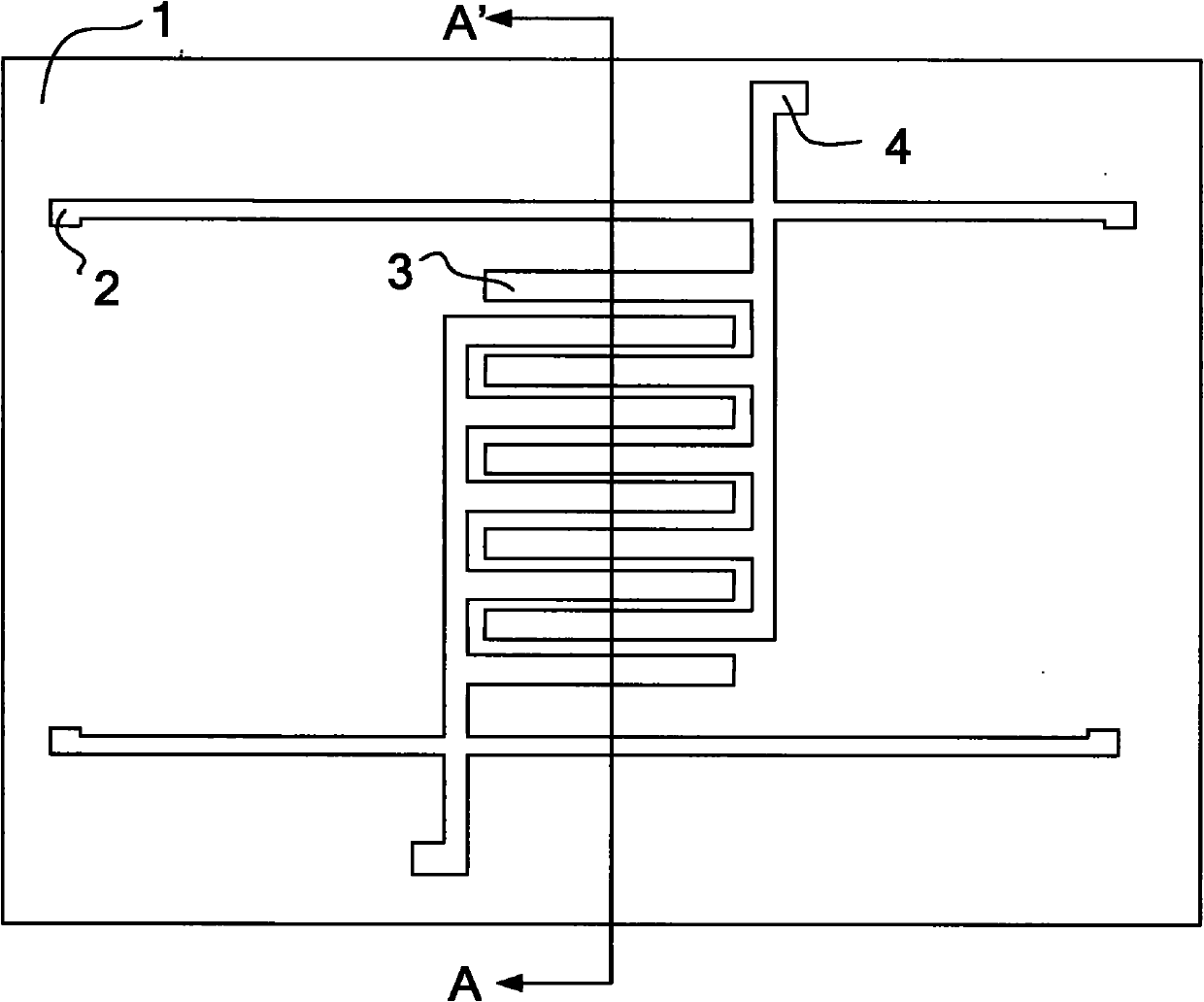

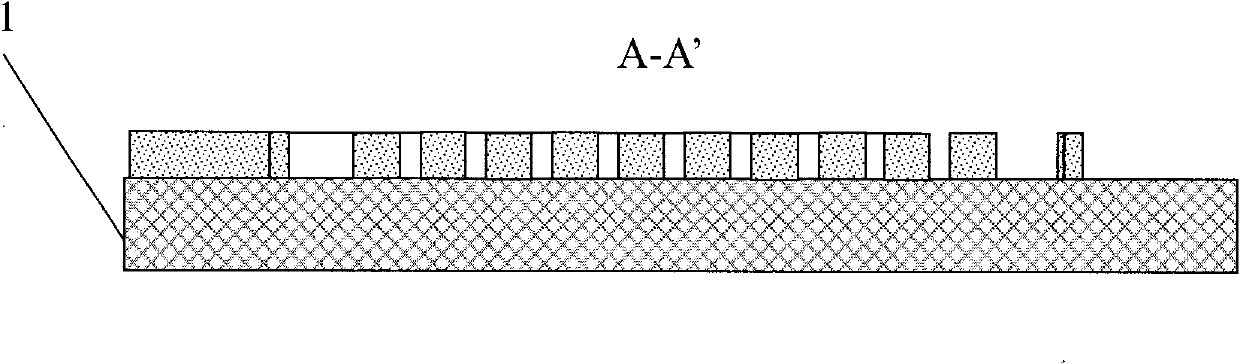

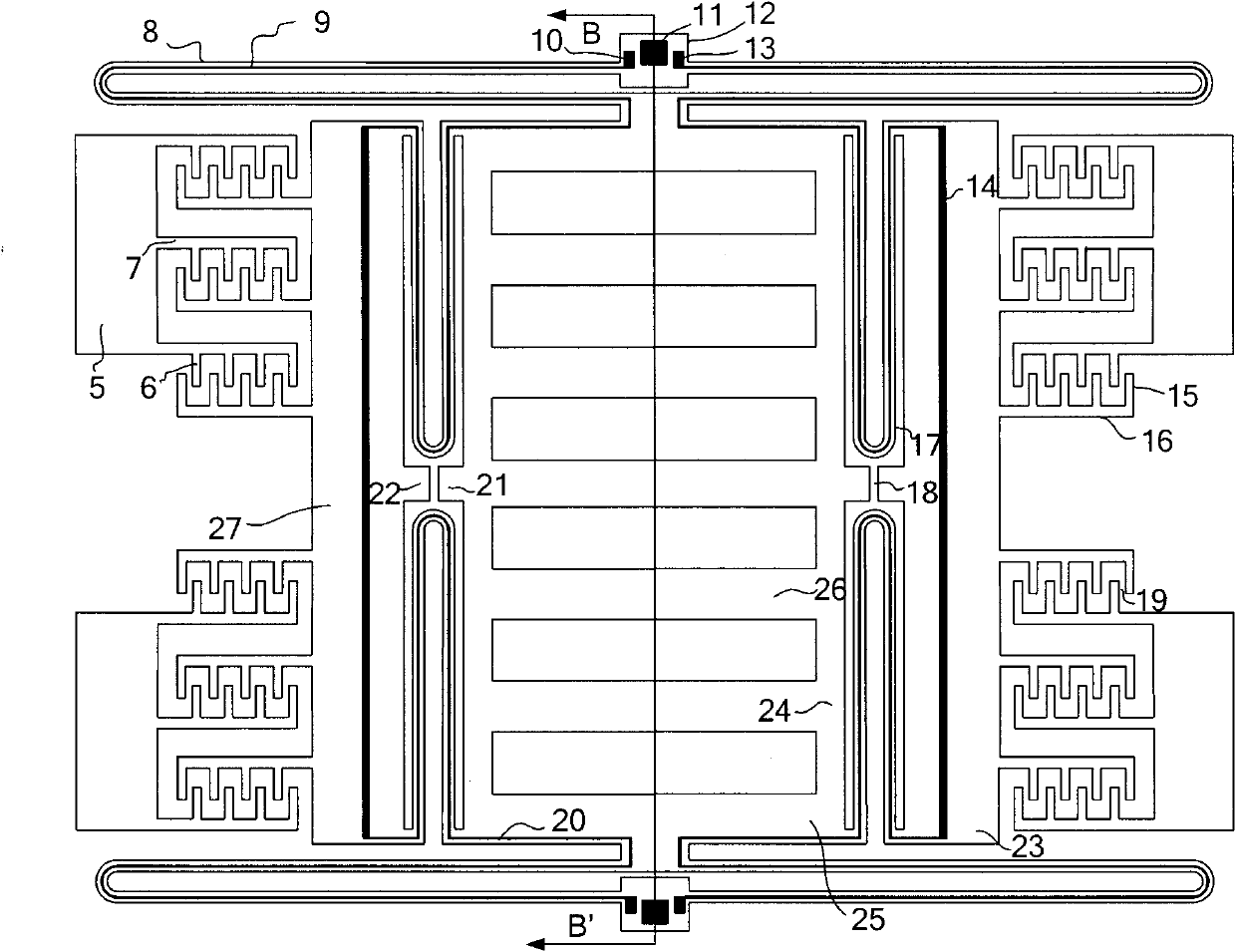

[0035] Embodiments of the present invention relate to a capacitive micro-inertial sensor, referring to Fig. 1(a), Fig. 1(b), Fig. 2(a), Fig. 2(b), image 3 , Figure 4 and Figure 5 On the first substrate 1, two sets of interdigitated fixed counter electrodes for detection are formed, corresponding to the connection coupling electrodes 2 between the fixed mass blocks, and the connection lines between the coupling electrodes 2 and the extraction electrodes 4, and the detection cross combs The tooth-shaped fixed counter electrode is composed of comb-teeth electrodes 3 and lead-out electrodes that cross relative to each other in the transverse direction; the sensor anchor point 12 fixed on the first substrate 1 is formed on the second substrate, and the sensor anchor point 12 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com