Continuous spraying air-cooled atomization and vaporization type condensing system and air-conditioning method

An atomization evaporation and condensation system technology, which is applied in the field of refrigeration equipment and air conditioning, can solve the problems of large space occupation, high equipment cost, and impracticability, and achieve the effects of reducing floor space, strengthening temperature control effect, and large spray area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

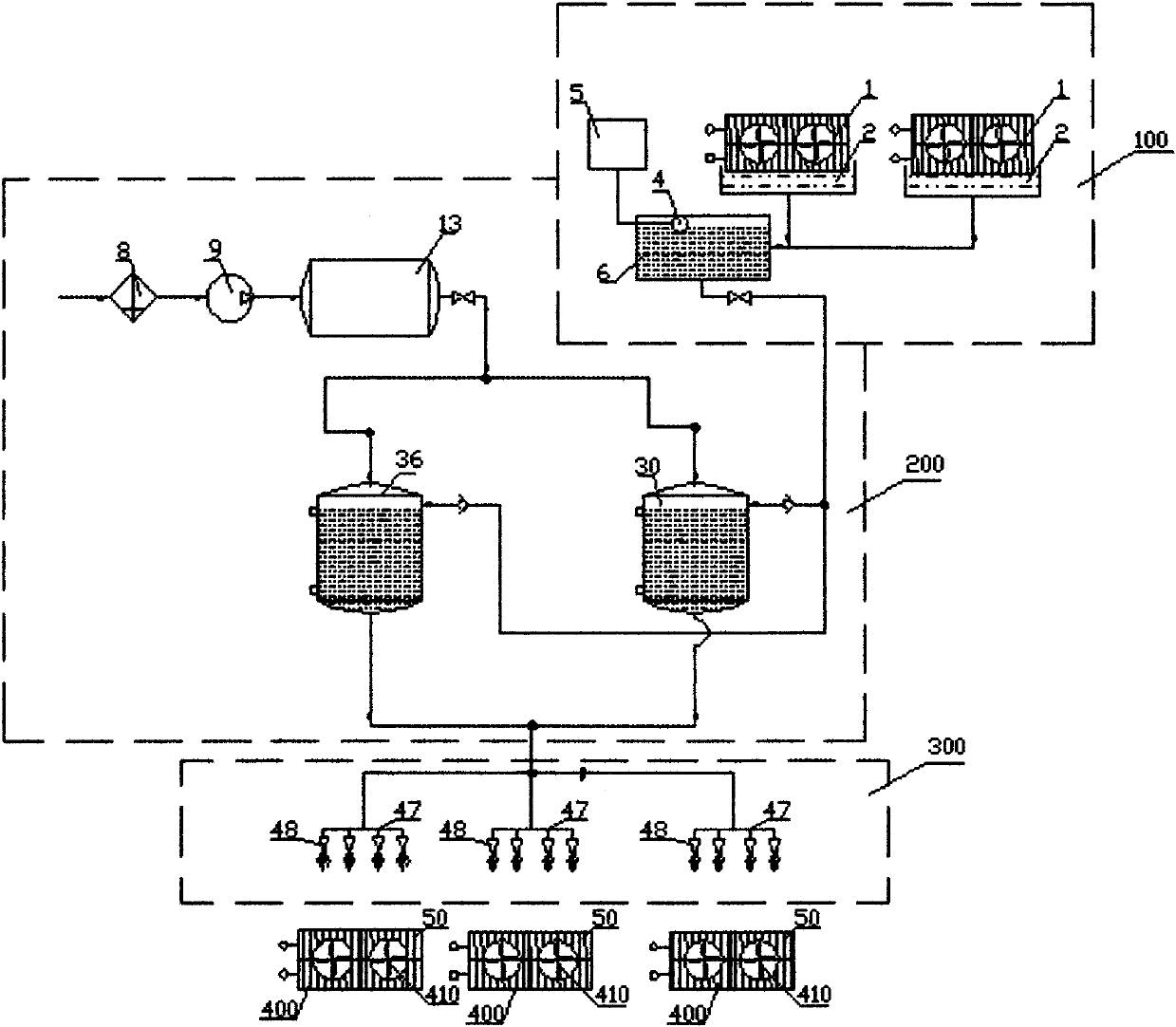

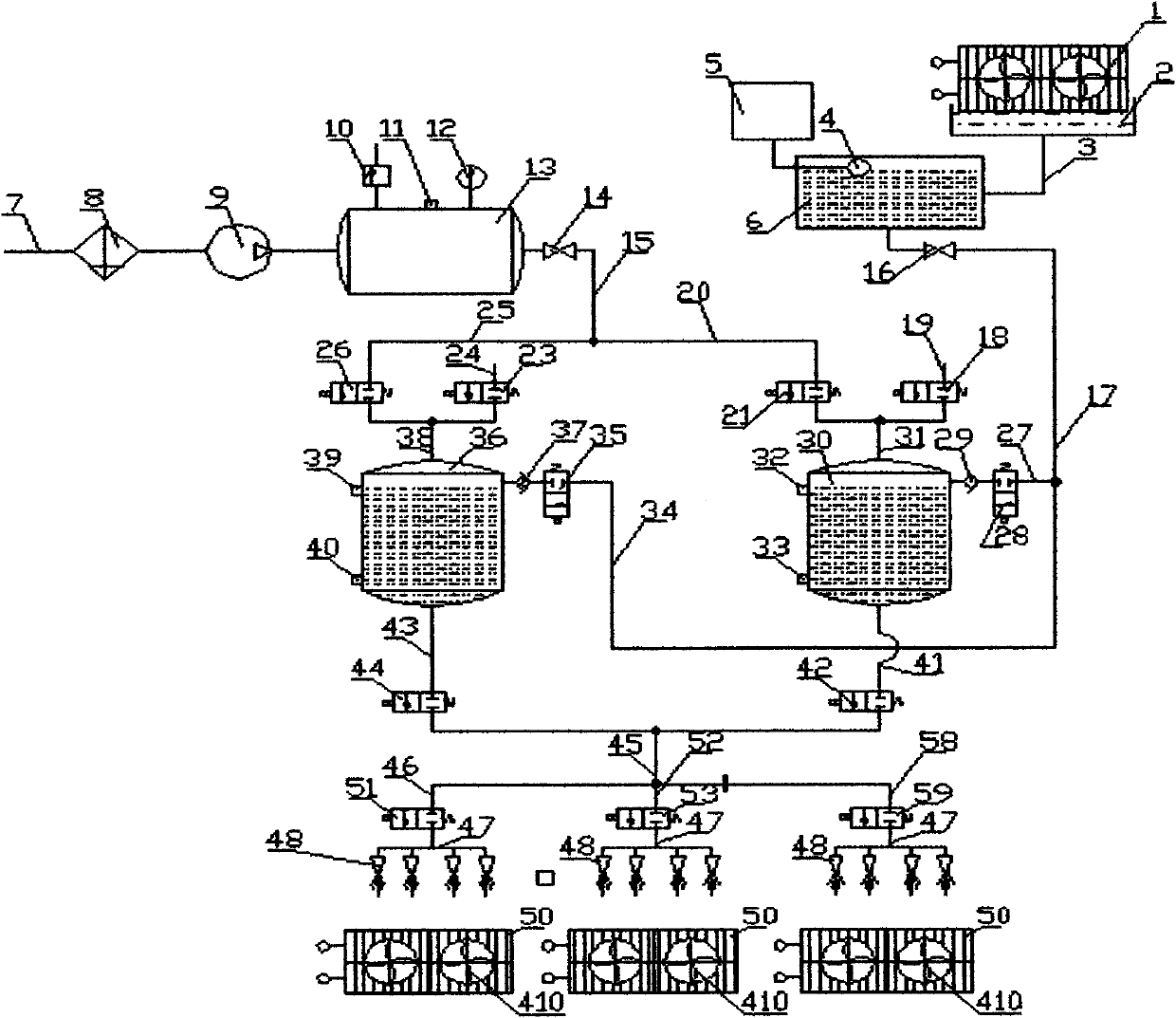

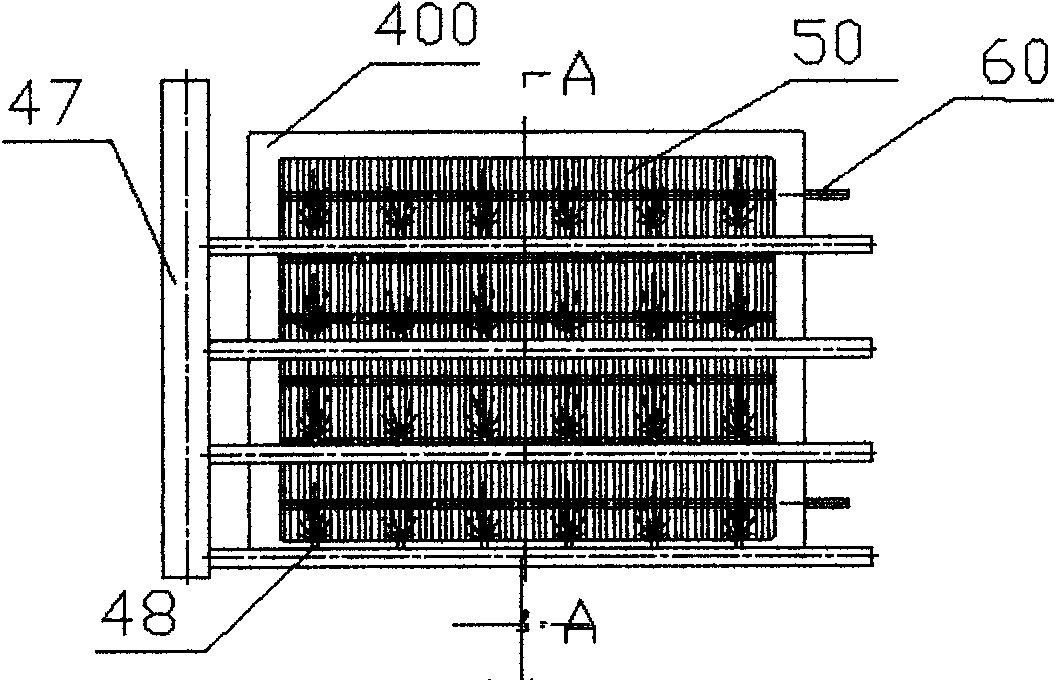

[0039] The air-cooled atomization evaporative condensing system capable of continuous spraying and the air conditioning method of the present invention will be described in detail below in conjunction with the accompanying drawings and by taking the specific implementation as an example. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

[0040] The working principle of the present invention is that a water storage device, an atomizing device and a pressurizing device are additionally installed on the air-cooled condenser. The water storage device includes a condensed water collection device and a pure water source, so that the pure water source can be supplemented in the case of insufficient condensed water, which can not only fully recycle the condensed water on the evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com