Lithium ion battery structure and preparation method thereof

A lithium-ion battery and battery technology, applied in the direction of secondary batteries, structural parts, battery pack parts, etc., can solve the problems of not optimizing the sealing performance and barrier performance of packaging films, accelerating electrochemical corrosion, changing the composition of electrolyte, etc. Achieve excellent air tightness, slow down the decay rate, prevent leakage and moisture ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

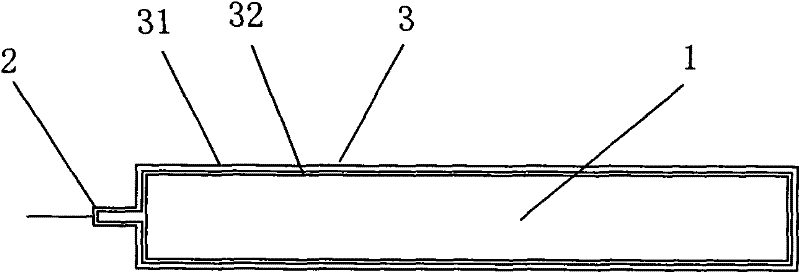

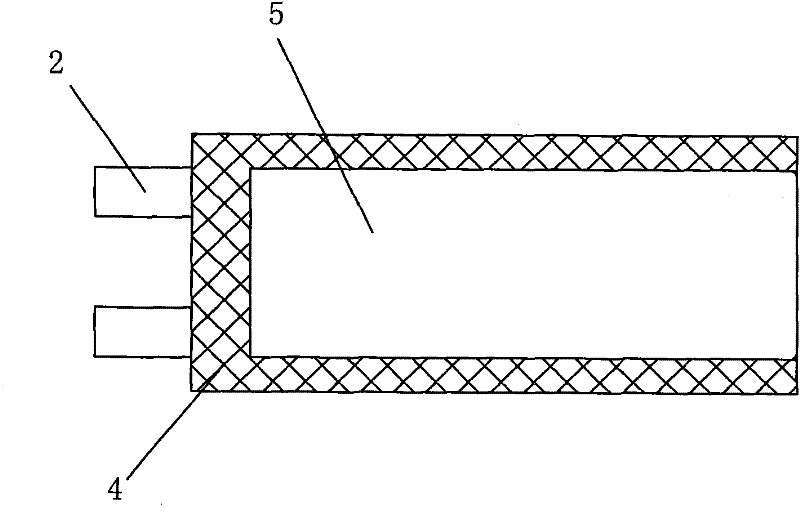

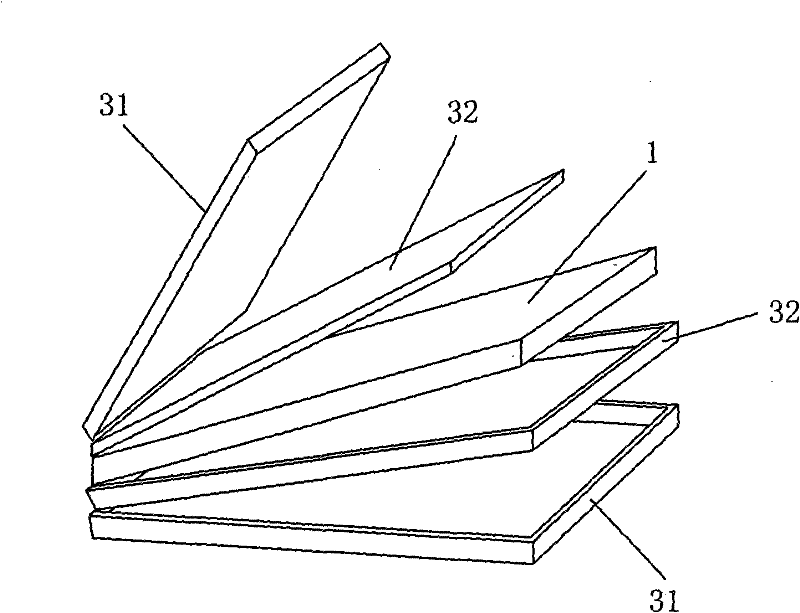

Embodiment 1

[0038] Example 1: After mixing the positive electrode active material LiCoO2, conductive carbon black and conductive graphite in different proportions, PVDF was used as a binder to prepare a slurry; the negative active material MCMB, conductive carbon black, dispersant and binder The agent is mixed according to the mass ratio of 90:2:4.5:3.5, and then prepared into a slurry. Use a coating machine to evenly coat the positive electrode slurry on the aluminum foil, and evenly coat the negative electrode slurry on the copper foil. After vacuum drying at 80°C for 8 hours, roll pressing to make positive and negative electrode sheets, namely: lead-out electrode 2 The diaphragm is a polypropylene microporous film with a thickness of 0.020 mm, which is wound into a battery cell 1, and the packaging film 3 is an aluminum-plastic composite film, which is formed by cold stamping and covered with a double-layer packaging film, that is, the outer packaging film 31 and The inner packaging fi...

Embodiment 2

[0039] Example 2: After mixing the positive active material lithium iron phosphate, conductive carbon black and conductive graphite in different proportions, PVDF was used as a binder to prepare a slurry; the negative active material artificial graphite, conductive carbon black SP, dispersed After the agent SBR and the binder CMC are mixed according to the mass ratio of 91:1.5:4.5:3, the slurry is prepared. Use a coating machine to evenly coat the positive electrode slurry on the aluminum foil, and evenly coat the negative electrode slurry on the copper foil. After vacuum drying at 80°C for 8 hours, roll pressing to make positive and negative electrode sheets, that is, to make lead-out The electrode 2; the diaphragm is a 0.030 mm thick polypropylene microporous film, which is wound into the cell 1 . The packaging film 3 is an aluminum-plastic film, and the gas storage chamber is reserved first, and sealed with a pulse sealing machine; the electrolyte solution 1 mol / L LiPF6 / Ec...

Embodiment 3

[0040] Embodiment 3: After mixing the positive electrode active material ternary material, conductive carbon black and conductive graphite in different proportions, PVDF is used as a binder to prepare a slurry; the negative electrode active material artificial graphite, conductive carbon black, and dispersant After mixing with the binder at a mass ratio of 90:2:4.5:3.5, the slurry was prepared; the positive electrode slurry was evenly coated on the aluminum foil with a coating machine, and the negative electrode slurry was evenly coated on the copper foil. After vacuum drying at ℃ for 8 hours, roll pressing to make positive and negative electrode sheets. The diaphragm is a polypropylene microporous film, which is wound into a cell 1 . The packaging film 3 is an aluminum-plastic film, formed by a bag-making process, and ultrasonically bonded and heat-sealed. The electrolyte is 1 mol / L LiAsF6 / EMP-BF4. Activate in the opening of the vacuum activation cabinet. Pre-sealed on an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com