Magnetic recording medium and magnetic recording/reproducing device

A magnetic recording medium and magnetic recording layer technology, applied in magnetic recording, data recording, recording information storage, etc., can solve problems such as inability to orientate, Ni-W alloy cannot maintain a face-centered cubic structure, and achieve high recording density characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (Example 1, Comparative Example 1)

[0060] The vacuum chamber in which the HD glass substrate is placed is pre-evacuated to 1.0×10 -5 Below Pa.

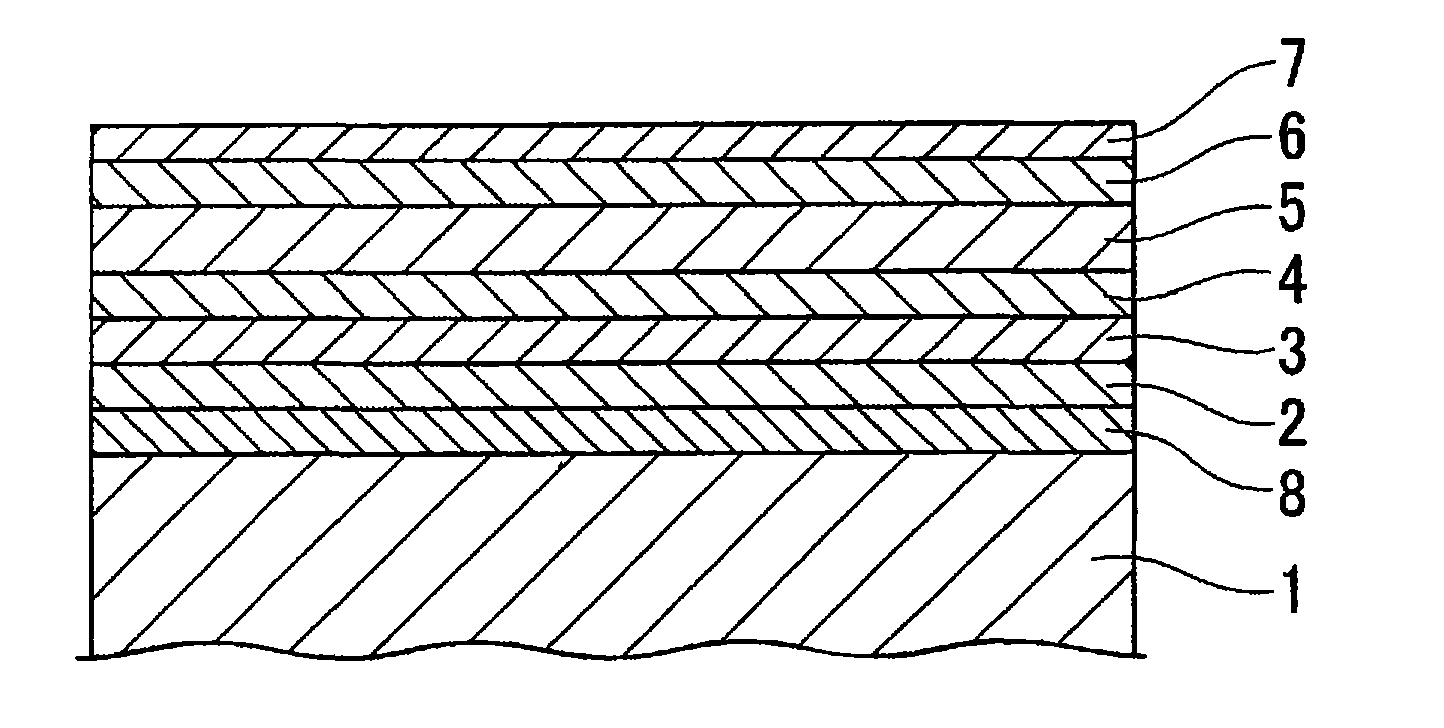

[0061] Next, a 50 nm-thick soft magnetic backing layer Co10Ta5Zr was formed on the substrate by sputtering in an Ar atmosphere at a pressure of 0.6 Pa.

[0062] Next, Cu10Cr, Cu20Cr, Cu10V, Cu20V, Cu10W, Cu20W, Ag10V, Ag20V, Au10W, Au20W (atomic) films were formed with a thickness of 5 nm in an Ar atmosphere at a pressure of 0.6 Pa as seed layers, and further 8 nm films were formed. A thick Ru film was used as the first intermediate layer (Examples 1-1 to 10). Ru films each having a thickness of 12 nm were formed as the second intermediate layer in an Ar atmosphere having a gas pressure of 5 Pa. As a comparative example, Cu, Cu30Cr, Cu30V, Cu30W, Ag, Ag30V, Au, Au30W films were formed as seed layers with a thickness of 5 nm in an Ar atmosphere at a gas pressure of 0.6 Pa (Comparative Examples 1-1 to 8). Furthermore, the f...

Embodiment 2

[0067] (Example 2, Comparative Example 2)

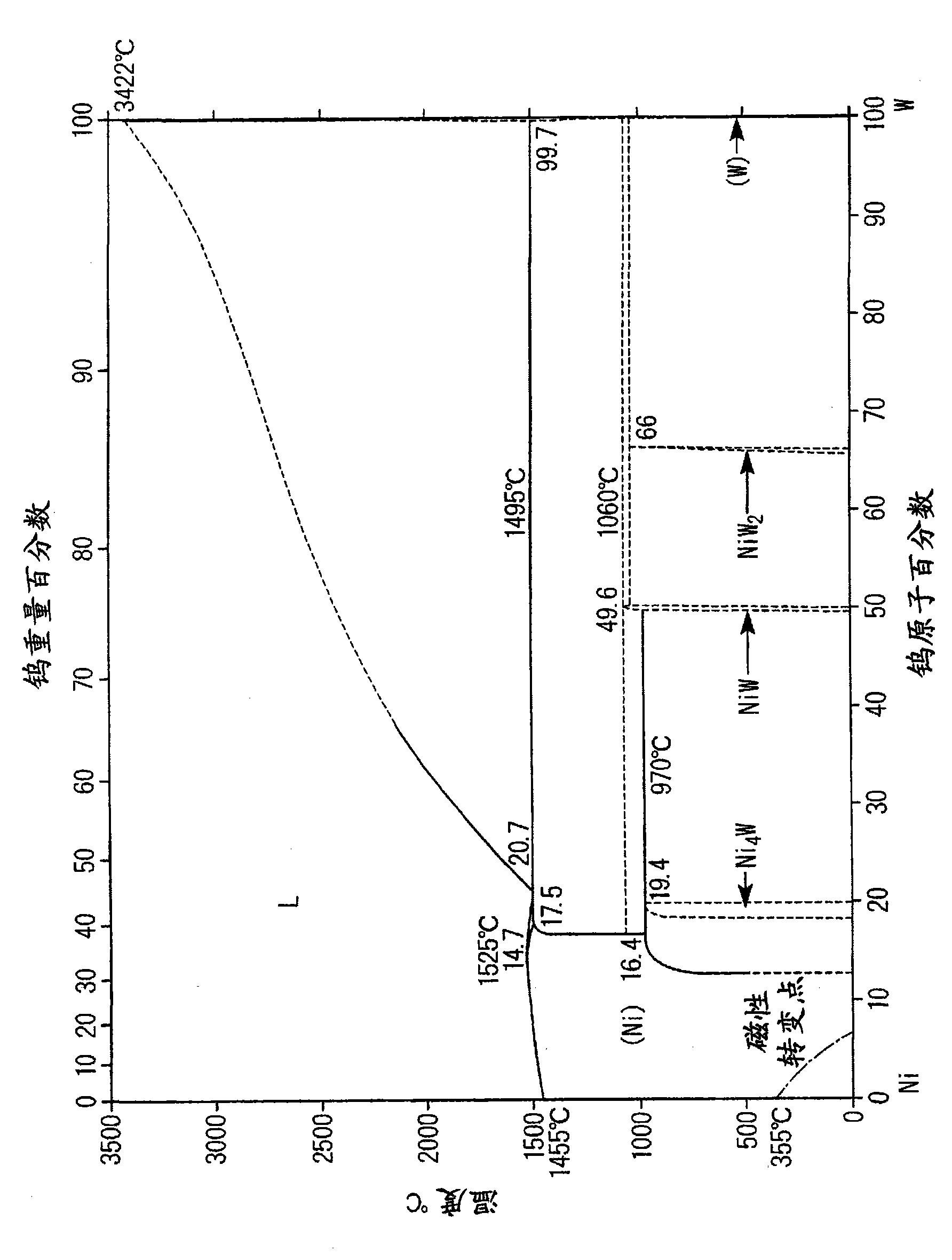

[0068] In the same manner as in Example 1, a soft magnetic layer was formed on a glass substrate. Cu10V, Cu20V, Cu10W, and Cu20W films were formed in an Ar atmosphere having a gas pressure of 0.6 Pa as seed layers with a thickness of 8 nm (Examples 2-1 to 4). In addition, as a comparative example, Ni, Ni10V, Ni20V, Ni30V, Ni10W, Ni20W, Ni30W films were formed as seed layers with a thickness of 8 nm in an Ar atmosphere having a gas pressure of 0.6 Pa (Comparative Examples 2-1 to 7).

[0069] Next, a 10 nm thick Ru film was formed in an Ar atmosphere with a pressure of 0.6 Pa as the first intermediate layer, and a 10 nm thick Ru-2TiO 2 (mol%) as the second intermediate layer. Furthermore, the formation of 91 (Co19Cr19Pt)-9 (SiO 2 ) film as a magnetic recording layer and a carbon film as a protective layer to make a perpendicular magnetic recording medium.

[0070] For Examples and Comparative Examples, the high signal-to-noise rati...

Embodiment 3

[0073] A soft magnetic layer was formed on a glass substrate in the same manner as in Example 1. Cu10Nb and Cu10Mo films with a film thickness of 8 nm were formed as seed layers in an Ar atmosphere at a gas pressure of 0.6 Pa (Examples 3-1 and 3-2). In addition, as Comparative Example 2, Cu10Ni, Cu10Pt, Cu10Mn, and Cu10Mg films each having a film thickness of 8 nm were formed as seed layers in an Ar atmosphere at a gas pressure of 0.6 Pa (Comparative Examples 3-1 to 4).

[0074] Next, in the same manner as in Example 2, a 10 nm thick Ru film was formed in an Ar atmosphere with a gas pressure of 0.6 Pa as the first intermediate layer, and a 10 nm thick Ru-2TiO film was formed in an Ar atmosphere with a gas pressure of 10 Pa. 2 (mol%) film as the second intermediate layer. Furthermore, the formation of 91 (Co19Cr19Pt)-9 (SiO 2 ) film as a magnetic recording layer and a C film as a protective layer to make a perpendicular magnetic recording medium.

[0075] For Examples and Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com