Magnetic recording medium, method for production thereof, and magnetic recording and reproducing device

A magnetic recording medium and magnetic recording technology, applied in the directions of magnetic recording, data recording, recording information storage, etc., can solve the problems that the discrete magnetic track media manufacturing technology does not appear, achieve excellent track isolation characteristics, avoid the appearance of particles, and avoid signal The effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

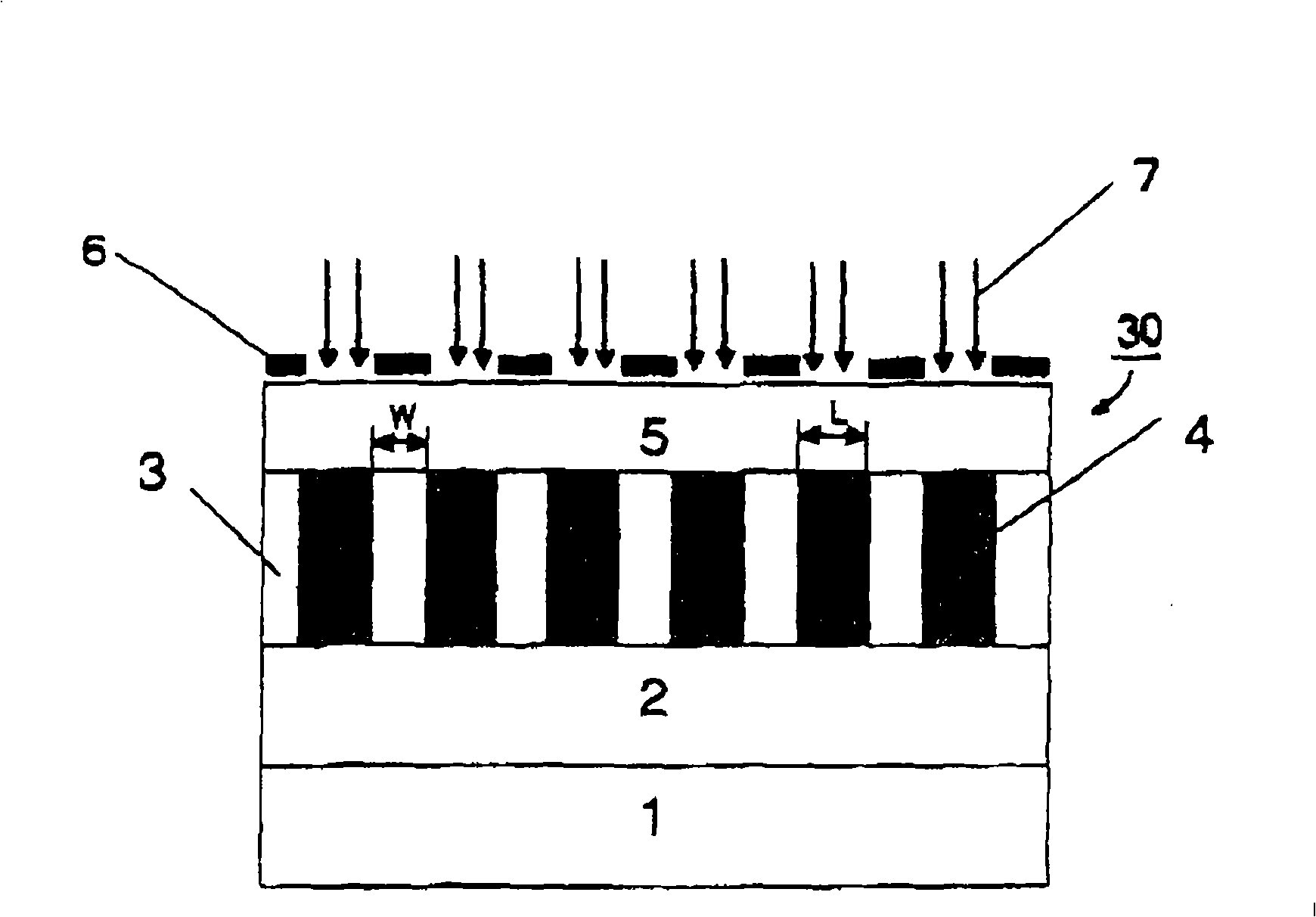

[0063] Similar to Comparative Example 2, the HD-oriented glass substrate was placed in a vacuum chamber, and the vacuum chamber was pre-evacuated to 1.0 × 10 -5 Pa or lower. The glass substrate used here is a Li 2 Si 2 o 5 、Al 2 o 3 -K 2 O, MgO-P 2 o 5 and Sb 2 o 3 - ZnO glass ceramics. The substrate had an outer diameter of 65 mm, an inner diameter of 20 mm, and an average surface roughness (Ra) of 2 Angstroms.

[0064] On the glass substrate, a FeCoB soft magnetic layer, a Ru interlayer and a 70Co-5Cr-15Pt-10SiO 2 Alloy magnetic layer, and further lamination of C (carbon) protective film layer and fluorine-based lubricating film by P-CVD method, the order of each layer is as described above. The thickness of the FeCoB soft magnetic layer is 600 angstroms, the thickness of the Ru intermediate layer is 100 angstroms, the thickness of the magnetic layer is 150 angstroms, and the average thickness of the C (carbon) protective film is 4 nm.

[0065] Afterwards, a mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com