Self-propelled tray

A self-propelled, palletized technology, applied in rigid containers, containers, packaging, etc., can solve the problem of inconvenient movement of workpieces, and achieve the effects of stable items, speeding up, and convenient and flexible movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

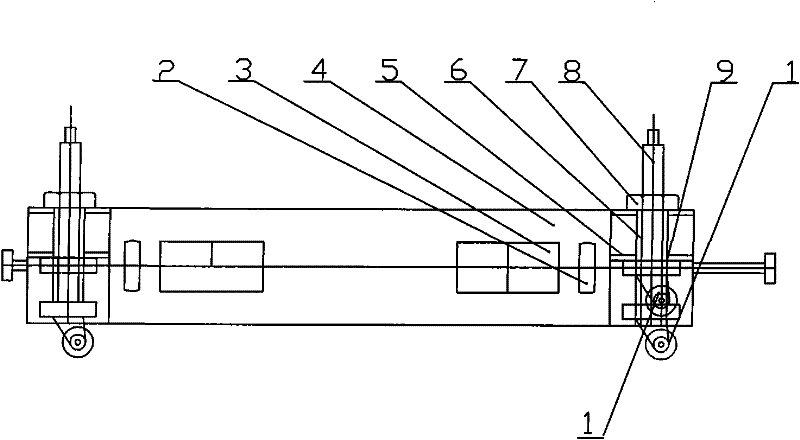

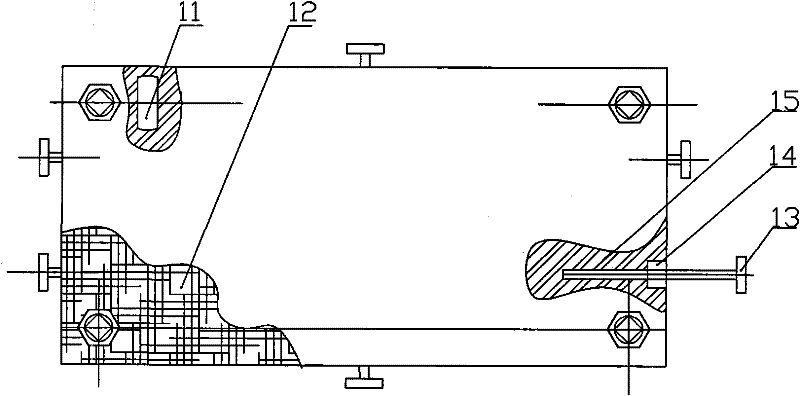

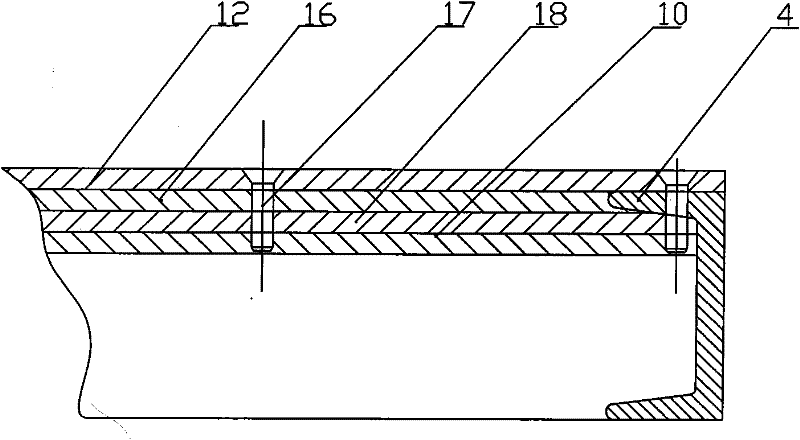

Embodiment 1

[0027] As shown in the figure, the outer dimensions of the tray body are designed as follows: length 1860mm, width 1360mm, height 185mm. Each of the four corners of the tray is equipped with a liftable universal caster 1 assembly. The caster 1 adopts a low-center-of-gravity structure. The load capacity of each caster 1 is 540kg. The caster model can be adjusted according to different needs, and the total load of the pallet is 2160kg. , the caster 1 can also be adjusted up and down, and the lifting stroke is 100mm. When the caster 1 retracts to the bottom plane of the tray body, it can be used as an ordinary tray, such as figure 1 Casters shown in retracted state. When the casters extend out of the bottom plane of the tray body, they can easily move by themselves, such as figure 1 Casters shown extended. The assembly structure of lifting caster is that caster 1 and connecting plate 9 are screwed together with four bolts. The connecting plate 9 is welded together with the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com