Water-mixing regulating method and device of secondary network system of heat exchange unit

A technology of heat exchange unit and adjustment method, which is applied in the directions of heating system, heating method, space heating and ventilation details, etc., can solve the problems of increasing the area of the plate heat exchanger and increasing the cost, and achieves obvious energy saving effect and prolonged The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

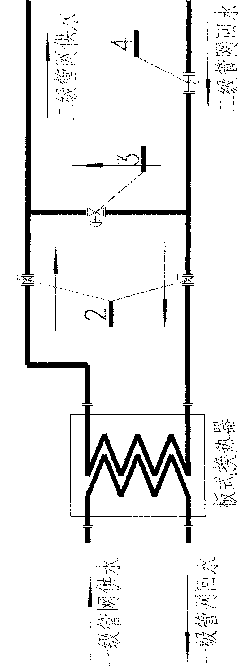

Image

Examples

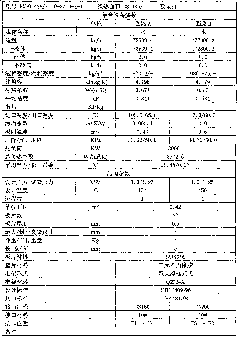

Embodiment 1

[0016] Compared with Table 1, for a set of 3MW heat exchange units, the design temperature of the inlet / outlet of the primary network is 100 / 65°C, and the design requirement of the inlet / outlet temperature of the secondary network is 45 / 55°C. Through the solution of the present invention, the flow regulating valve on the parallel connecting pipe is adjusted so that 2 / 3 of the water volume of the secondary network at a temperature of 45°C enters the plate heat exchanger, and the temperature of the water outlet of the plate heat exchanger is 60°C; the temperature is 45°C The other 1 / 3 of the water in the stage network is mixed with the water at the outlet temperature of the heat exchanger at 60°C through the connecting pipe, and the temperature after mixing is exactly 55°C, which meets the design requirements. The selected model of the plate heat exchanger is BRb0.42m-28.14m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com