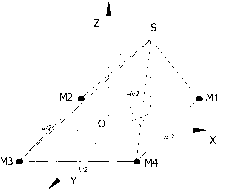

Boiler pressure-bearing pipe leakage positioning method for planar four-element array power station

A technology of power plant boilers and plane four, which is applied in the directions of positioning, boiler working status indication, radio wave measurement system, etc., can solve the problem of spending a lot of manpower and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

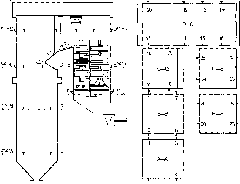

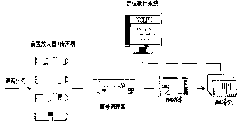

Method used

Image

Examples

Embodiment 1

[0054] When the time delay estimation error is 1 μs, the adaptive Gauss mutation genetic algorithm is used, the population evolves through 16 generations, and the minimum fitness of the population is 26.1769, as Figure 5a As shown, the positioning result is (4.8805, 2.6297, 9).

Embodiment 2

[0056] When the time delay estimation error is 0.1μs, the adaptive Gauss mutation genetic algorithm is adopted, the population evolves through 157 generations, and the minimum fitness of the population is 0.1332, as Figure 5b As shown, the positioning result is (4.8693, 2.8716, 9.5692).

Embodiment 3

[0058] When the time delay estimation error is 0, the adaptive Gauss mutation genetic algorithm is adopted, the population evolves through 16 generations, and the minimum fitness of the population is 0.0071, as Figure 5c As shown, the positioning result is (5.007, 3.006, 10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com