Adjustable-depth counter boring device

A countersinking and depth technology, which is applied in the direction of manufacturing tools, drilling accessories, metal processing equipment, etc., can solve the problems of difficult manufacturing and processing and inconvenient operation, and achieve the advantages of reduced manufacturing and processing difficulty, convenient operation and simplified process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

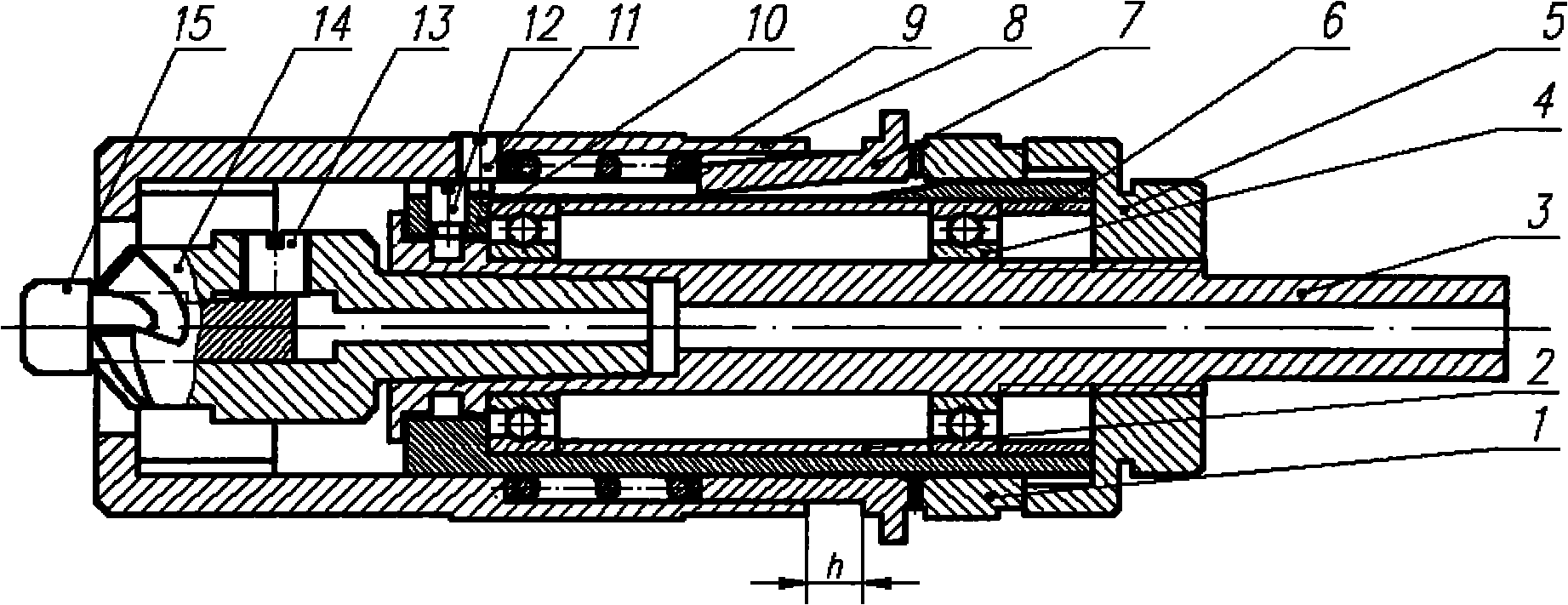

[0020] refer to figure 1 , The described countersinking tool of adjustable depth is mainly made up of three parts of countersinking bit 14, countersinking bit guide post 15, cutter bar 3 and adjustment mechanism.

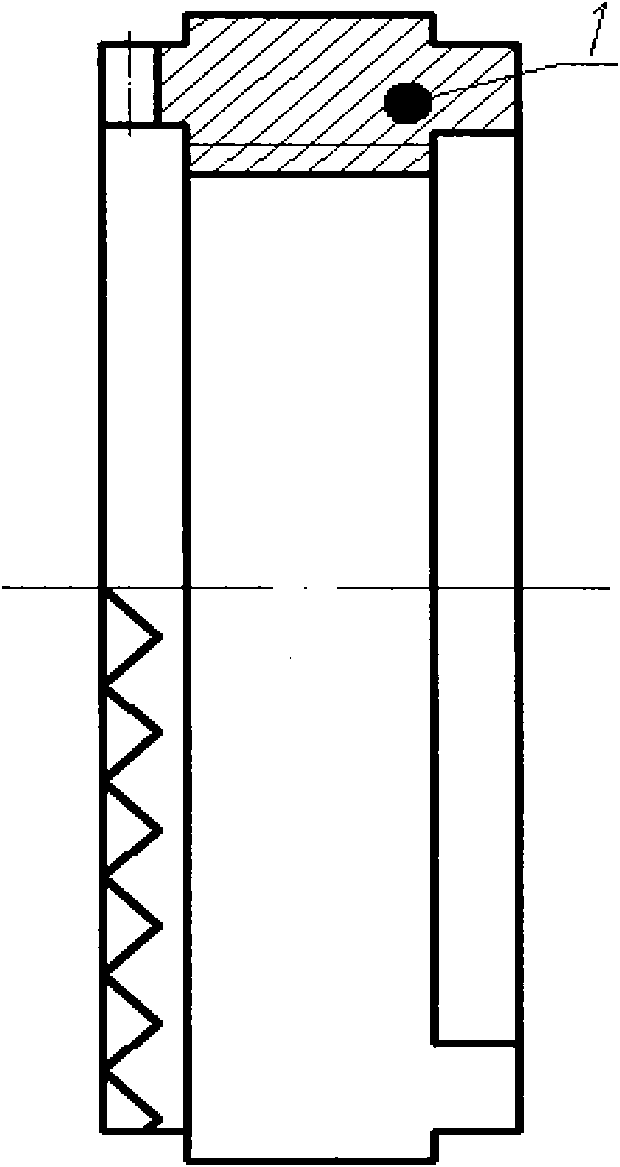

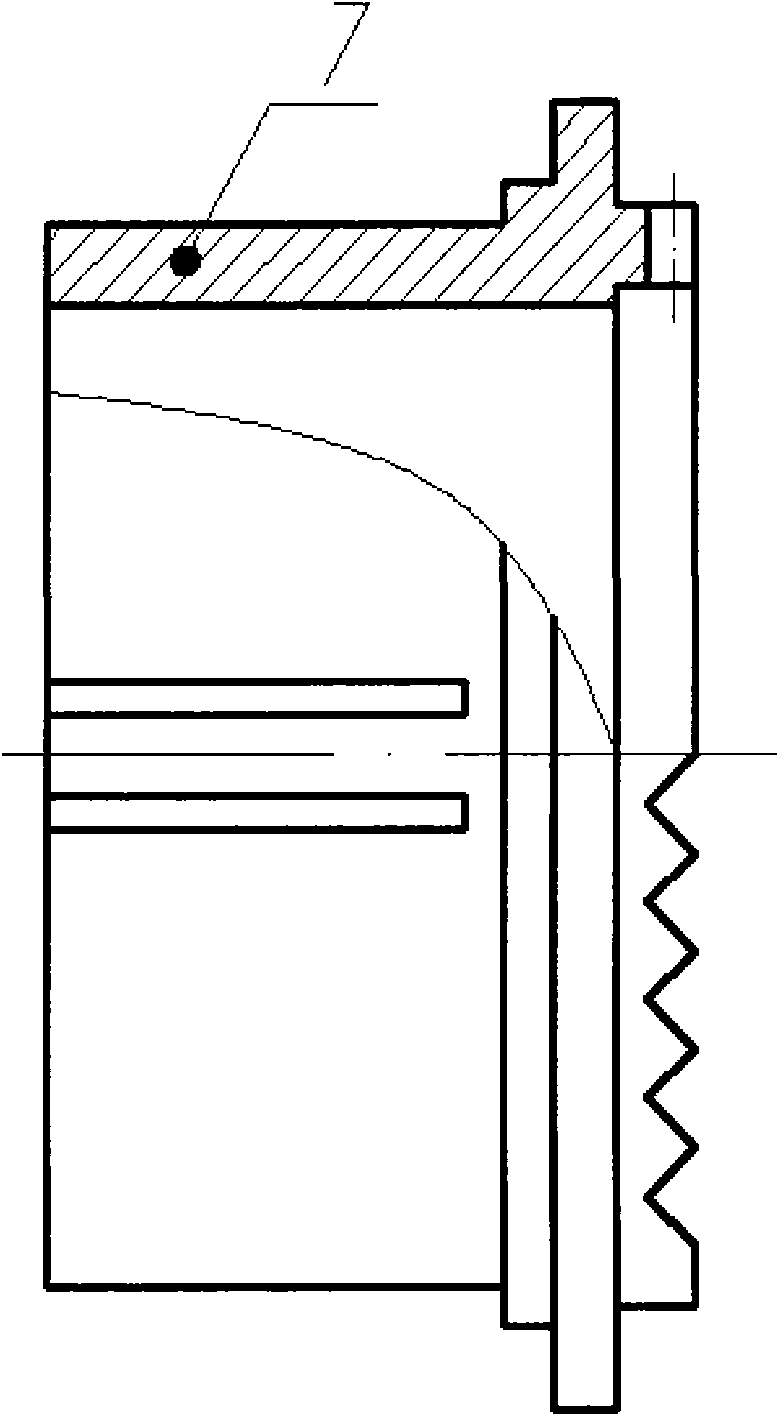

[0021] The countersink bit 14 is a rod-like structural part with a thick left side and a thin right side. A stepped through hole is arranged on the axial symmetry line of the countersink bit 14. The diameter of the through hole at the left end is greater than the diameter of the through hole at the right end. The left end of the countersink bit 14 In order to process a countersinking head with a cutting edge for countersinking on the left end conical surface, the cone angle of the countersinking head can be made into 60°, 90°, 120° or 150°, which can meet the requirements of different countersinking angles. The radial direction of the spot facing head 14 is provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap