Laser processing head

A laser processing head and laser processing technology, used in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as increased processing costs and high cost constraints, to reduce overall costs, achieve miniaturization, and achieve high density. integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific embodiments.

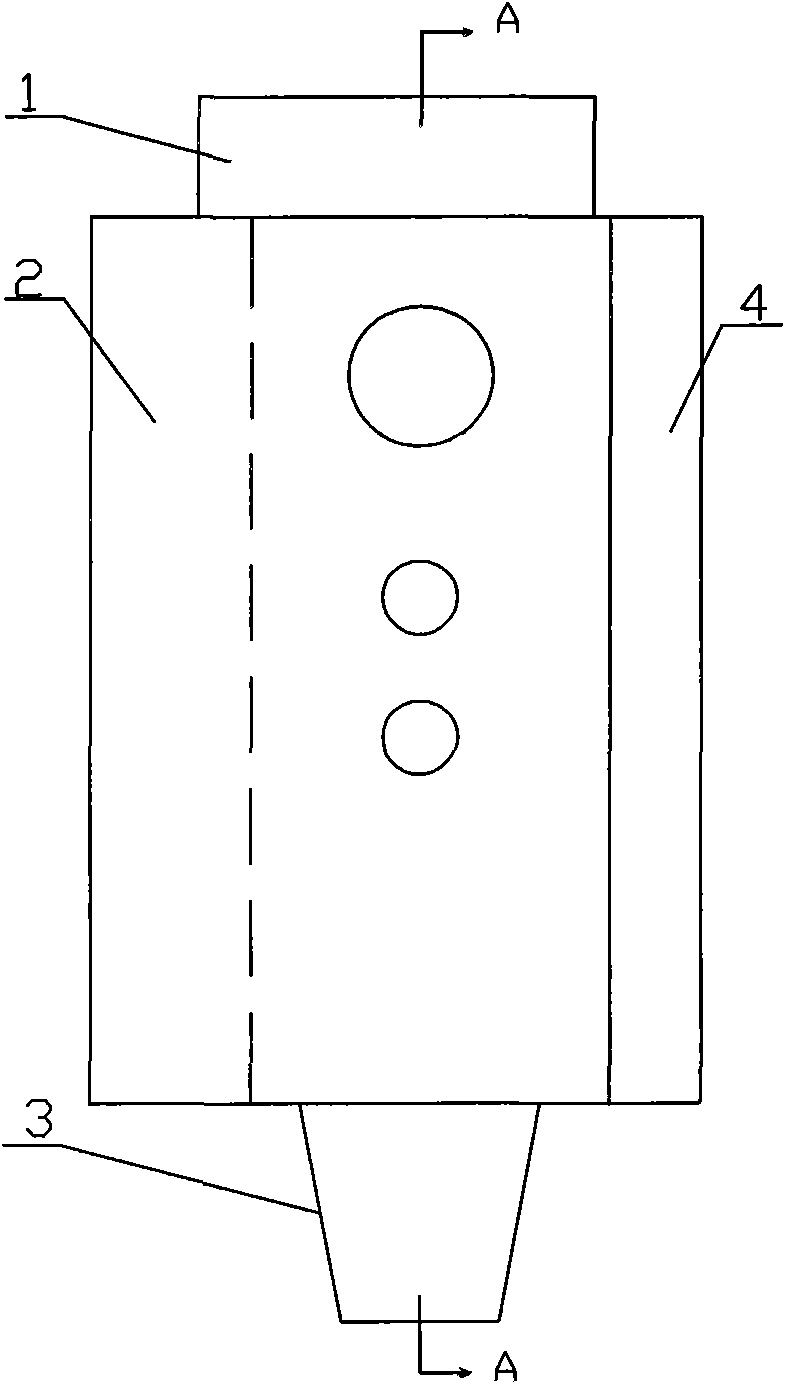

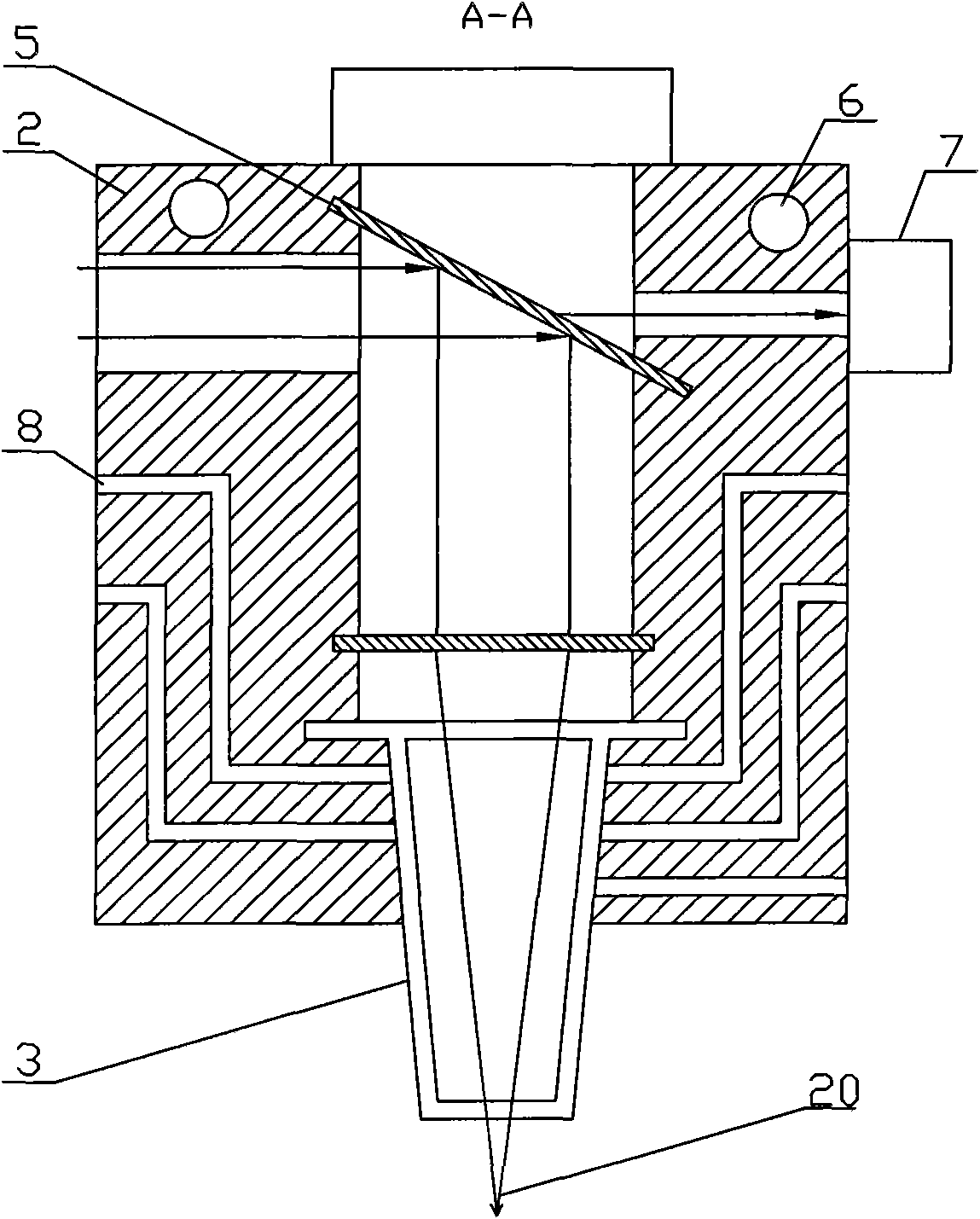

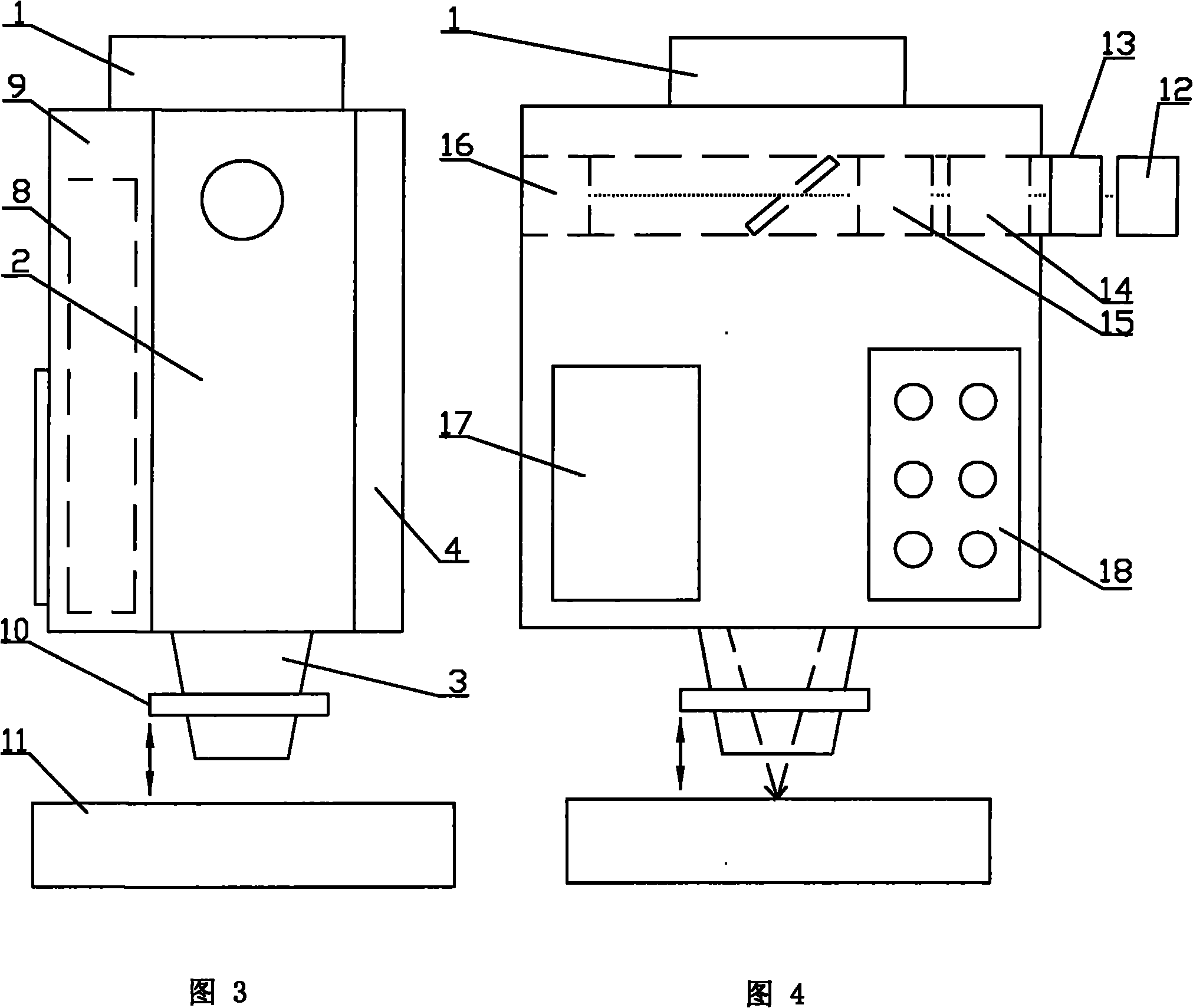

[0034] like figure 1 , figure 2 As shown, the main board is assembled and connected to the packaging board. The laser processing head in the present invention simplifies numerous cylindrical parts into a three-dimensional structure in which the board unit is superimposed. The board unit mainly includes the main board 2 and the packaging board 4, and the main board 2 and the packaging board 4 Assembly connections. The main board 2 is a flat plate made of high thermal conductivity materials such as copper and aluminum. The top of the main board 2 is connected to the CCD 1 , and the bottom is connected to the nozzle 3 . A cavity required for the nozzle 3 is formed between the main board 2 and the packaging board 4 , and the upper part of the nozzle 3 is accommodated in the cavity. There are mounting holes 6 on the main board 2 . A series of optical structures ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com