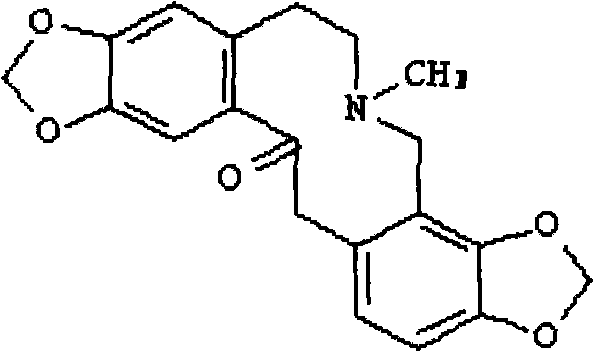

Method for purifying protopine from corydalis amabilis

A purification method and proto-opioid technology, applied in ultrafiltration, organic chemistry and other directions, can solve the problems of many toxic reagents and low resin specificity, and achieve the effects of increasing speed, reducing loss and increasing adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Extract. Weigh 20 kg of Xia Wu (original opium content 0.4%) and grind to 20 meshes, add 120L85% ethanol to reflux for extraction for 2 hours, filter, add 100L85% ethanol, reflux for 1 hour, filter, then add 100L85% ethanol, reflux for 1 hour; combine the three extracts to obtain 280L.

[0034] The second step: membrane separation. Concentrate the extract under reduced pressure until the alcohol concentration is 40%, and release it to obtain 80L of concentrated solution. Slowly add 240ml of concentrated acetic acid, fully stir, filter, add a microfiltration membrane system to filter, and then pass through a composite ultrafiltration membrane with a molecular cut-off of 3000. Ultrafiltration, Collect permeate.

[0035] The third step: mixed resin enrichment. The permeate was added to 10LAB-8 and 110 resin 3:1 mixed resin column for adsorption, the column flow rate was 5L / hour. During elution, first wash the neutral with deionized water, then use 60L of 50% et...

Embodiment 2

[0038] Step 1: Extract. Weigh 20 kg of Xia Wu (original opium content 0.4%) and pulverize into 40 meshes, first add 160L of 90% ethanol for reflux extraction for 2 hours, filter, then add 120L of 90% ethanol, reflux for 1 hour, and combine the extracts to obtain 240L .

[0039] The second step: membrane separation. Concentrate the extract under reduced pressure until the alcohol concentration is 30%, and release it to obtain 70L of concentrated solution, slowly add 140ml of concentrated acetic acid, stir well, filter, add microfiltration membrane system to filter, and then pass through a composite ultrafiltration membrane with a molecular cut-off of 3000. Collect permeate.

[0040] The third step: mixed resin enrichment. The permeate was added to 10LAB-8 and 110 resin 2:1 mixed resin column for adsorption, the column flow rate was 5L / hour. During elution, first wash the neutral with deionized water, then use 50L of 60% ethanol solution to elute impurities, and finally use ...

Embodiment 3

[0043] Step 1: Extract. Weigh 10 kg of Xia Wu (0.45% of the original opioid content) and pulverize into 20 meshes, first add 60L of 90% ethanol for reflux extraction for 2 hours, filter, then add 50L of 90% ethanol, reflux for 1 hour, filter, then add 50L of 90% ethanol was refluxed for 1 hour; the three extracts were combined to obtain 140L.

[0044] The second step: membrane separation. Concentrate the extract under reduced pressure until the alcohol concentration is 30%, and release it to obtain 40L of the concentrated solution, slowly add 40ml of concentrated acetic acid, stir thoroughly, filter, add a microfiltration membrane system to filter, and then pass through a composite ultrafiltration membrane with a molecular cut-off of 6000. Collect permeate.

[0045]The third step: mixed resin enrichment. The permeate was added to 5LAB-8 and 110 resin 3:1 mixed resin column for adsorption, the column flow rate was 5L / hour. During elution, first wash the neutral with deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com