Composite inhaul cable with totally-closed carbon fiber wires and high-strength steel wire

A carbon fiber filament and high-strength steel wire technology, applied in bridge parts, textiles and papermaking, textile cables, etc., can solve the problems of gas and harmful substances erosion, and achieve the effect of easy production quality, reducing the dead weight of the cable body, and improving the structure spanning ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

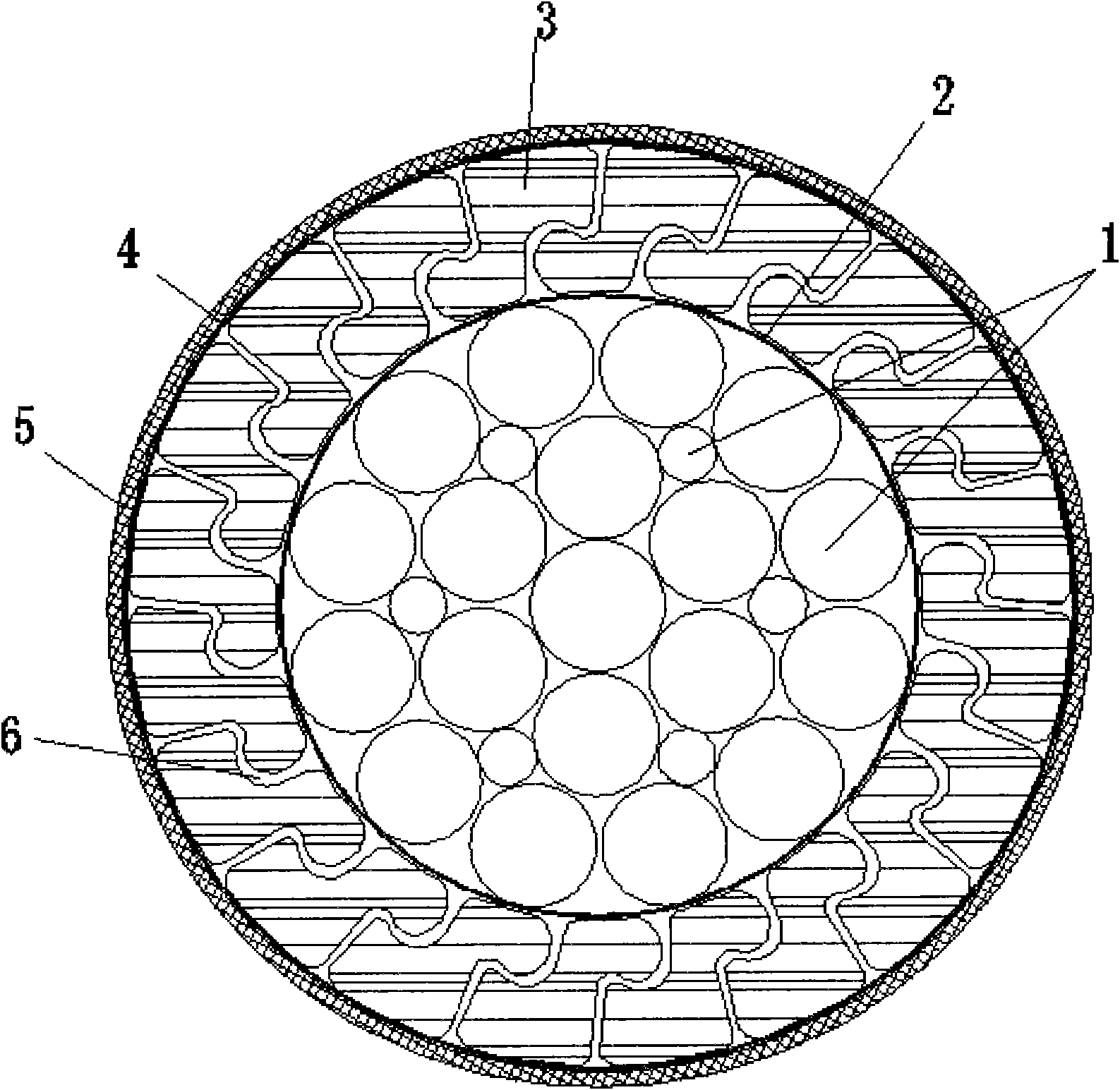

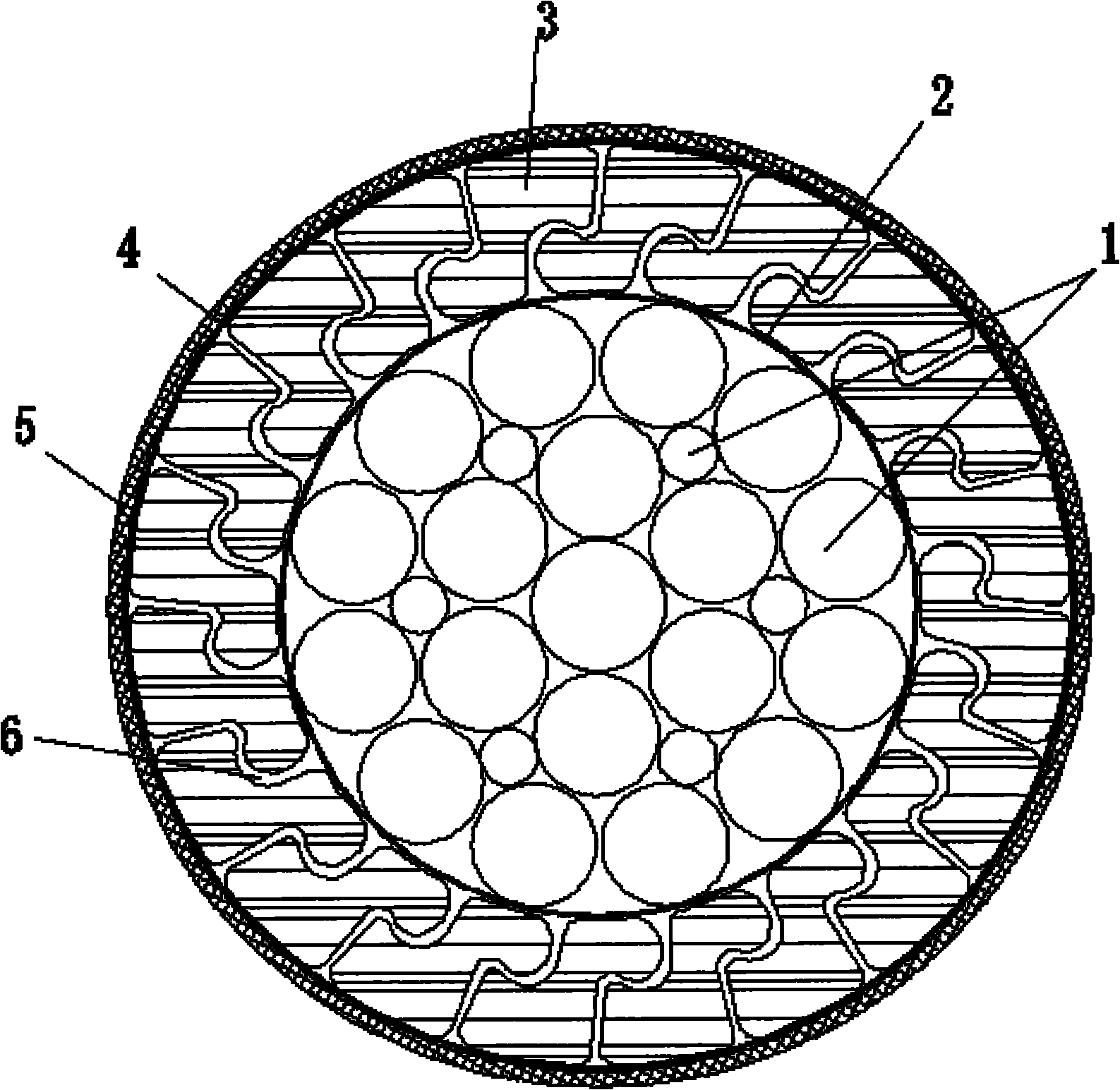

[0016] The fully enclosed carbon fiber wire and high-strength steel wire composite cable of the present invention includes a high-strength steel wire 1, an inner layer of polyester fiber high-strength wrapping tape 2, an outer layer of polyester fiber high-strength wrapping tape 4, external Z-shaped carbon fiber wires 3 and Outer peripheral high-density polyethylene sheath 5; wherein, the high-strength steel wire 1 is located at the core of the composite cable, and the inner layer of polyester fiber high-strength wrapping tape 2 is wound around the outer periphery of the high-strength steel wire 1, and the inner layer of polyester fiber high-strength wrapping tape The belt 2 is covered with Z-shaped carbon fiber filaments 3 interlocking with each other, and the outer polyester fiber high-strength wrapping tape 4 is wrapped around the Z-shaped carbon fiber filaments 3 interlocking with each other, and the outer polyester fiber high-strength wrapping tape 4 is wrapped Covered wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com