Vertical centrifugal hydroextractor

A vertical centrifuge and dehydrator technology, applied in the direction of drying solid materials, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of reducing machine reliability, high equipment manufacturing costs, scraper and screen wear, etc., to achieve Eliminate scraping and pushing wear and energy consumption, simple and compact structure, accurate and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

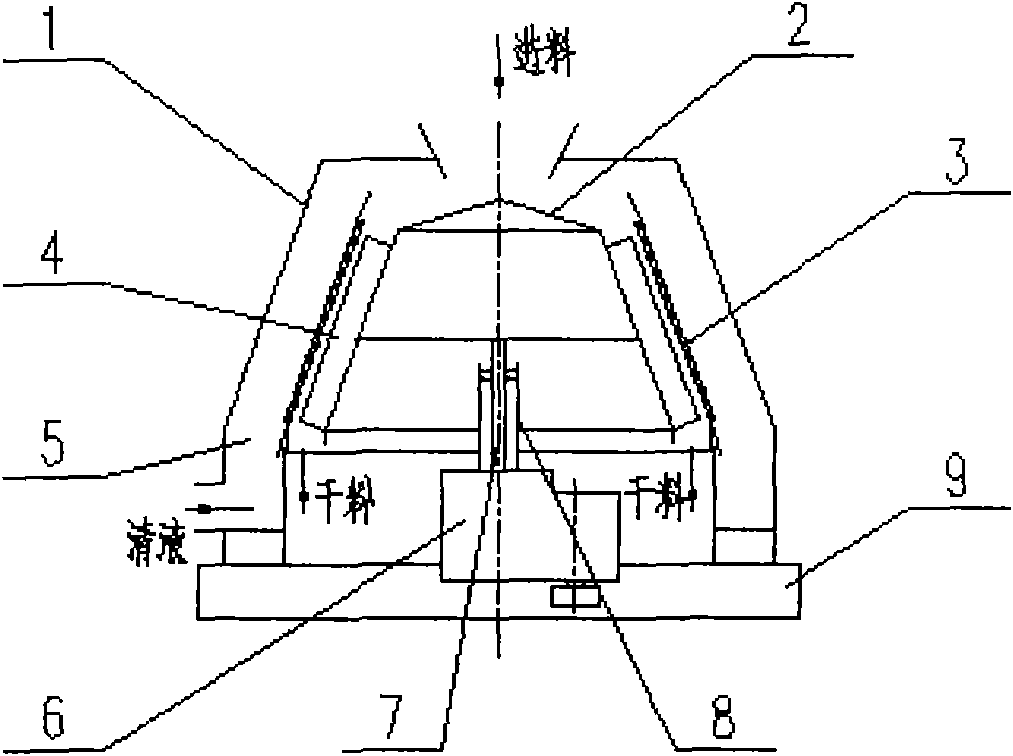

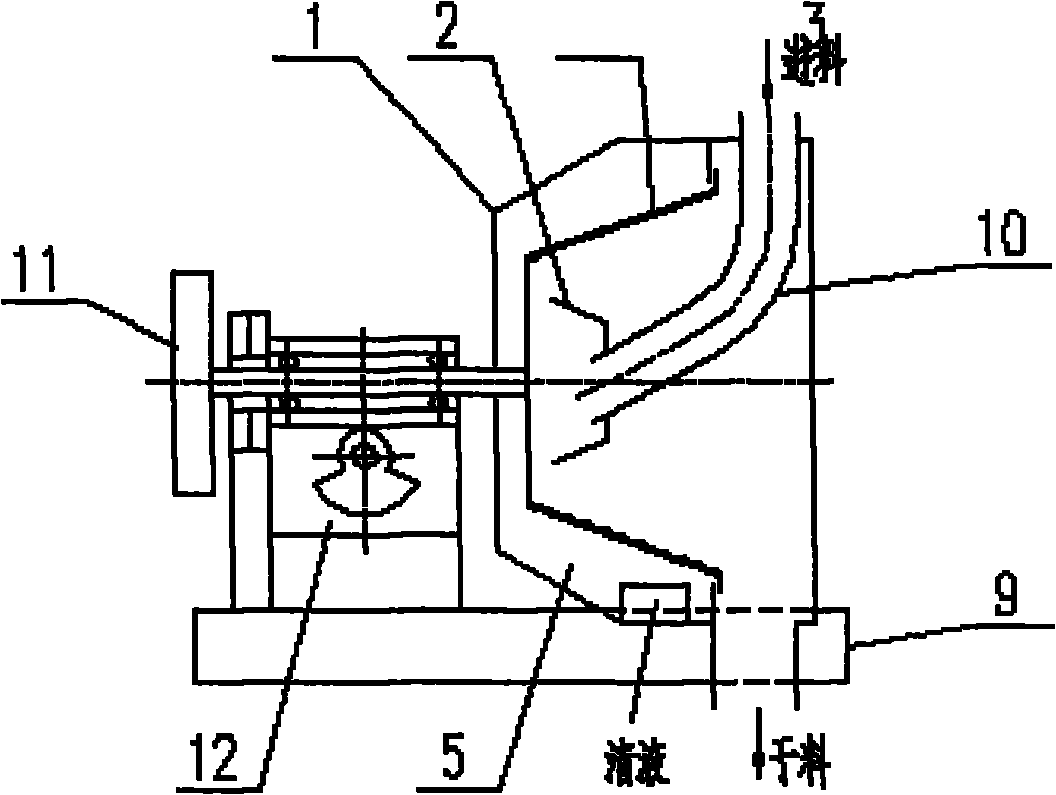

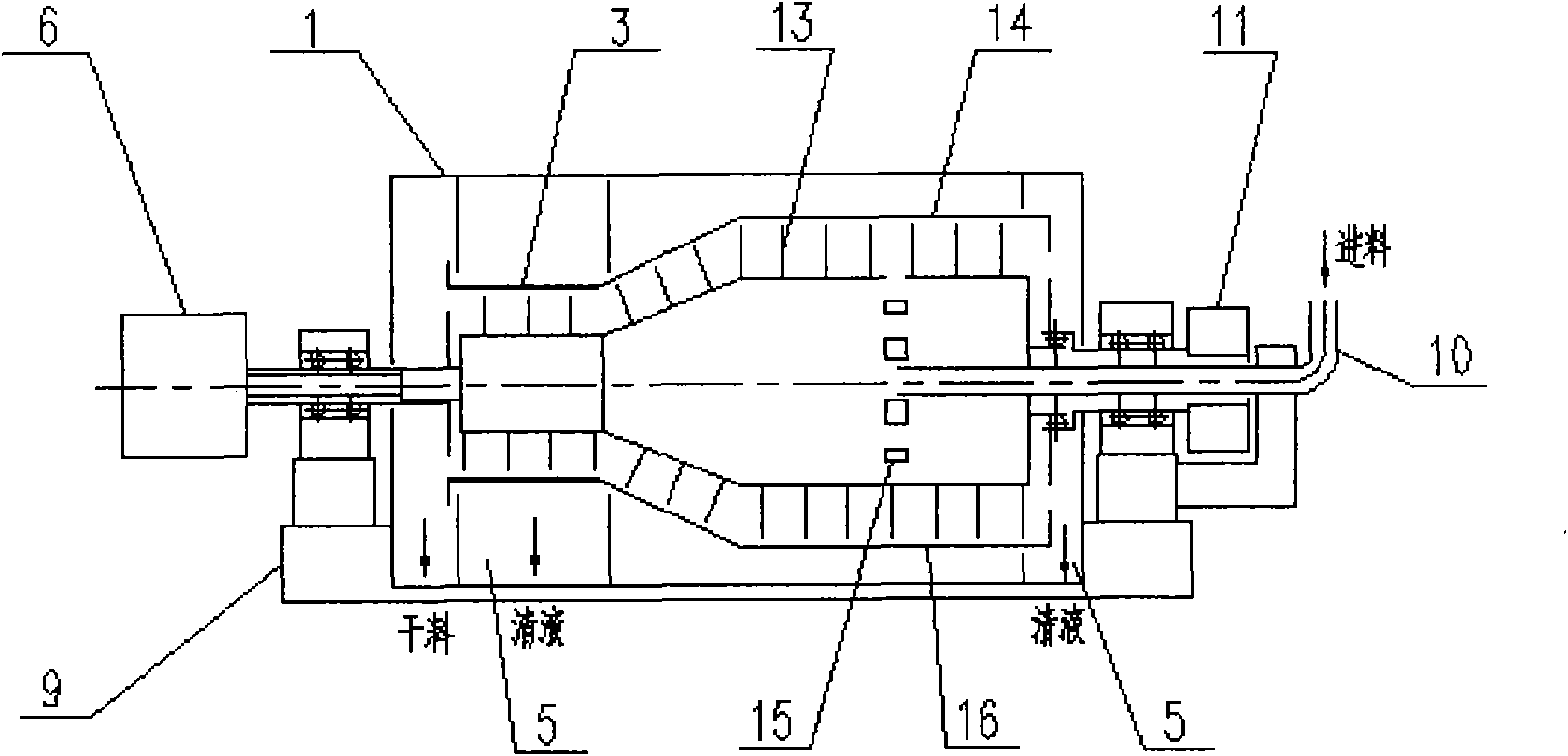

[0033] According to the present invention Figure 4 to Figure 7 According to the technical solution, the casing 1 and the differential gear 6 are respectively fixed on the base 9, and the output shaft of the differential gear 6 is an inner output shaft 7 and an outer output shaft 8 which are set together, and inner rotors 21 are respectively installed on the upper ends of the inner and outer output shafts. And the outer rotor 22, the upper and lower journals of the sieve plate 20 are rotationally connected with the outer rotor 22 through bearings, and the inner and outer rotors are established by a pin wheel rotation mechanism composed of a pin wheel 18 and a gear 19 (an incomplete gear transmission mechanism can also be used). Drive connection. When the machine is working, the motor drives the differential 6 to drive the inner and outer rotors to rotate at a differential speed through its inner output shaft 7 and outer output shaft 8, and the material is distributed from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com