Automatic gauge block calibrating device based on stepper motor

A technology of stepping motor and verification device, applied in the direction of measuring device, optical device, instrument, etc., can solve the problems of high skill requirements of measuring personnel, uneven force on measuring block, affecting measuring accuracy, etc., and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

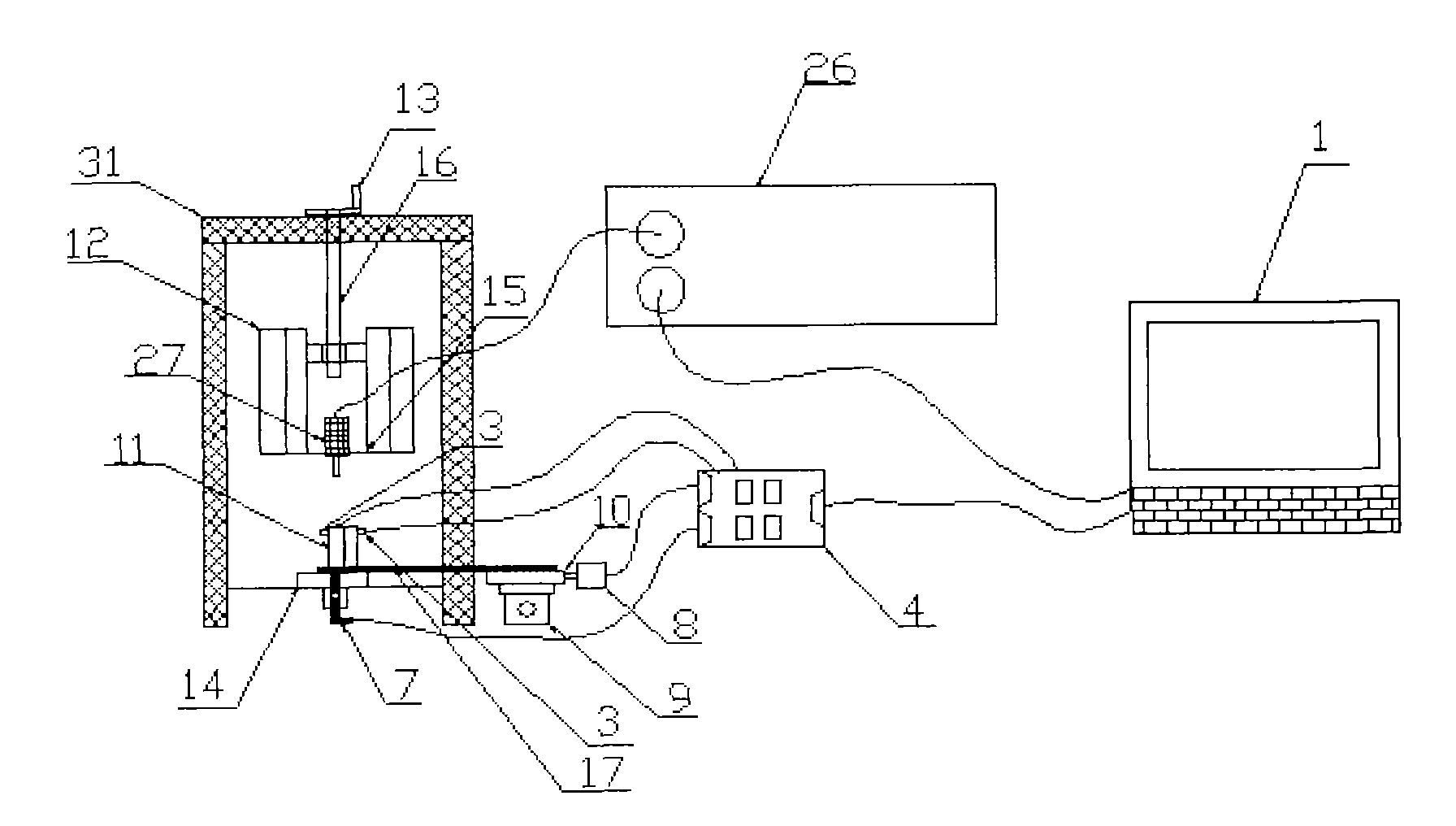

[0042] Specific embodiments are given below in conjunction with the accompanying drawings to further illustrate how the automatic verification device for gauge blocks based on stepping motors of the present invention is realized.

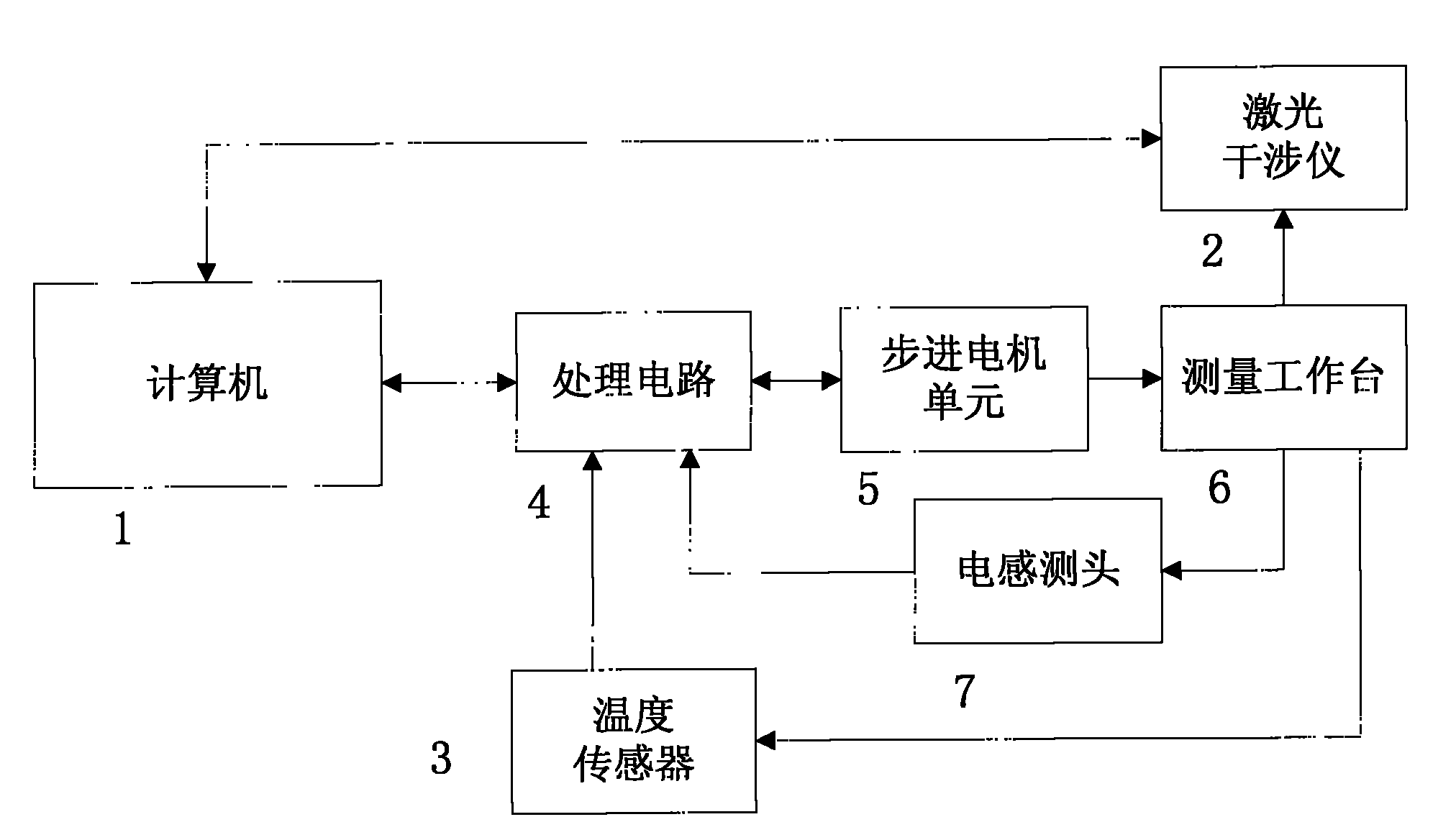

[0043] Such as figure 1 As shown, the automatic verification device for measuring blocks based on stepping motors of the present invention includes a computer 1, a laser interferometer 2, a temperature sensor 3, a processing circuit 4, a stepping motor unit 5, and a measuring block and a standard block Measuring workbench 6 and electric probe 7, wherein, described processing circuit 4 is connected with computer 1 by RS232, the input end of described stepper motor unit 5 is connected the processing circuit 4 that controls stepper motor work, output end Connect the measurement workbench 6 to drive the measurement workbench 6, the laser interferometer 2 and the electrical probe 7 are respectively clamped on the measurement workbench 6 for the detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com