Piezoresistive sensor circuit capable of automatically correcting zero-bias

A sensor circuit and automatic correction technology, applied in the direction of instruments, etc., can solve the problems of difficulty in guaranteeing capacitance, automatic correction circuit not suitable for piezoresistive sensors, inconvenience in use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

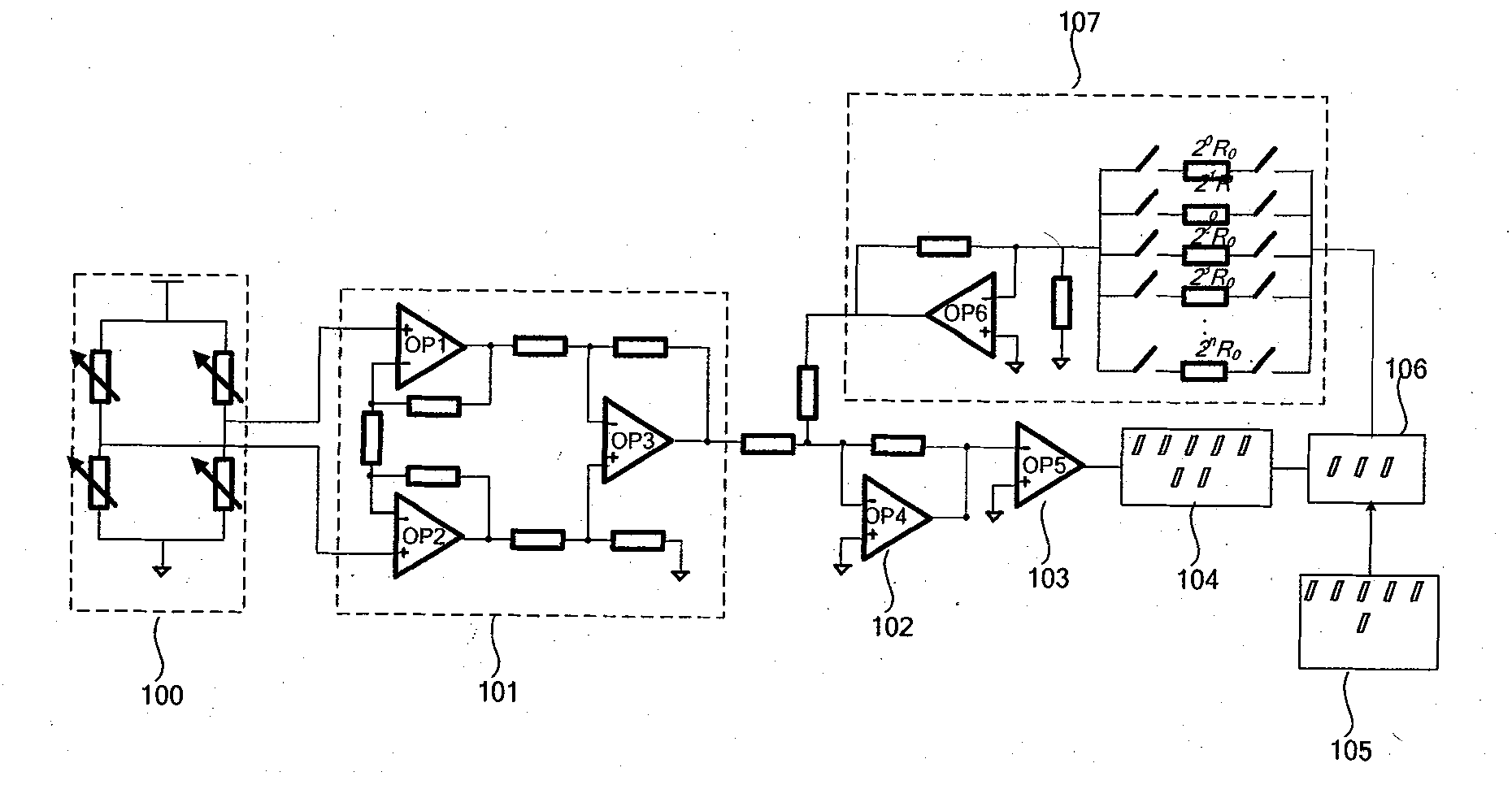

[0013] figure 1 A schematic diagram showing the circuit structure of the piezoresistive sensor with automatic zero point offset correction in this embodiment.

[0014] Such as figure 1 As shown, the interface circuit has: instrumentation amplifier part (101), subtractor part (102), comparator part (103), bidirectional reversible counter part (104), start control unit part (105), latch part ( 106), D / A converter part (107), subtractor part (108).

[0015] The instrument amplifier part (101) amplifies the differential mode voltage output by the piezoresistive sensor structure (100), which includes the zero point offset voltage of the piezoresistive sensor structure (100) caused by asymmetry, differential mode voltage and D / A conversion The correction voltage output by the device part (107) is output through the subtractor part (102), and the output result of the subtractor part (102) is compared with the center potential through the comparator part (103), and the output result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com