Method for simulating noise radiation and decomposing noise sources when automobile speeds up

A technology of accelerating driving and noise radiation, applied in the fields of automotive product development, noise control, and acoustic signal processing, which can solve the problems of increasing product development cycle and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

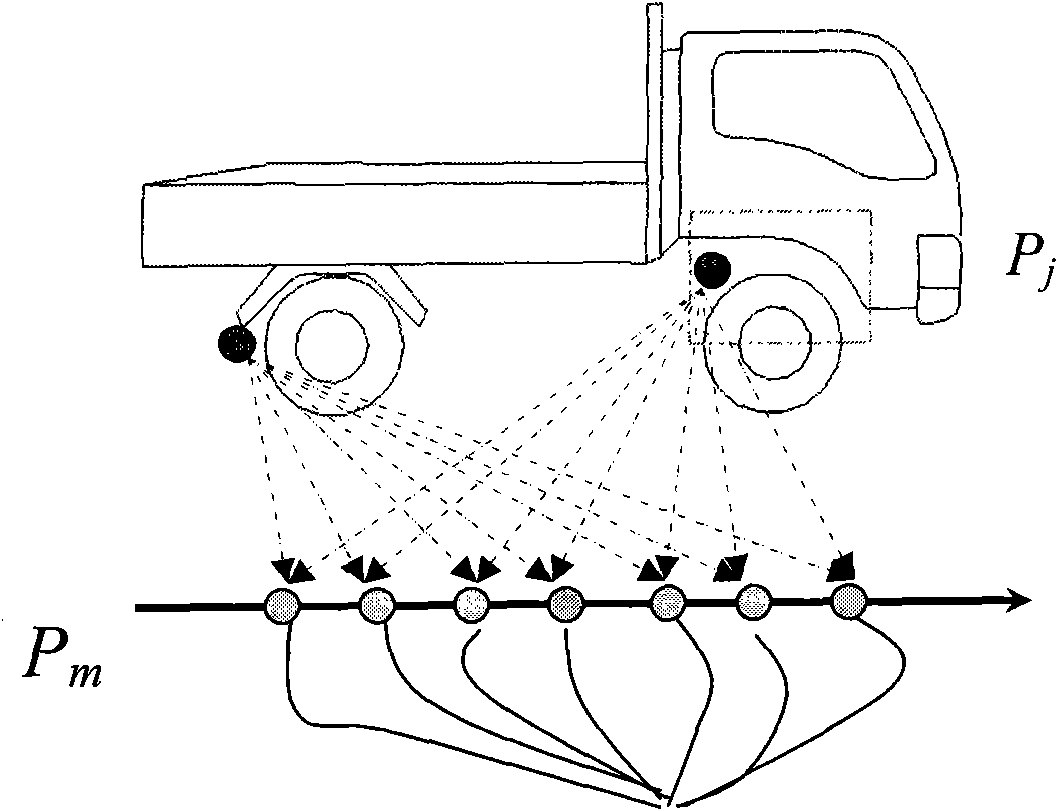

[0030] Such as figure 1 , 2 Shown is a principle schematic diagram and a dynamic schematic diagram thereof of the present invention;

[0031] 1.1 figure 1 It is a schematic diagram of the device, describing the general idea of the present invention, wherein the source refers to each noise source P j , figure 1 The noise source shown in is the engine and the exhaust port; the path is the transfer function in which the noise is emitted by the components and received by the receiver; the contribution is the total sound pressure level P received by the receiver m is the total contribution of each assembly component at this receiver.

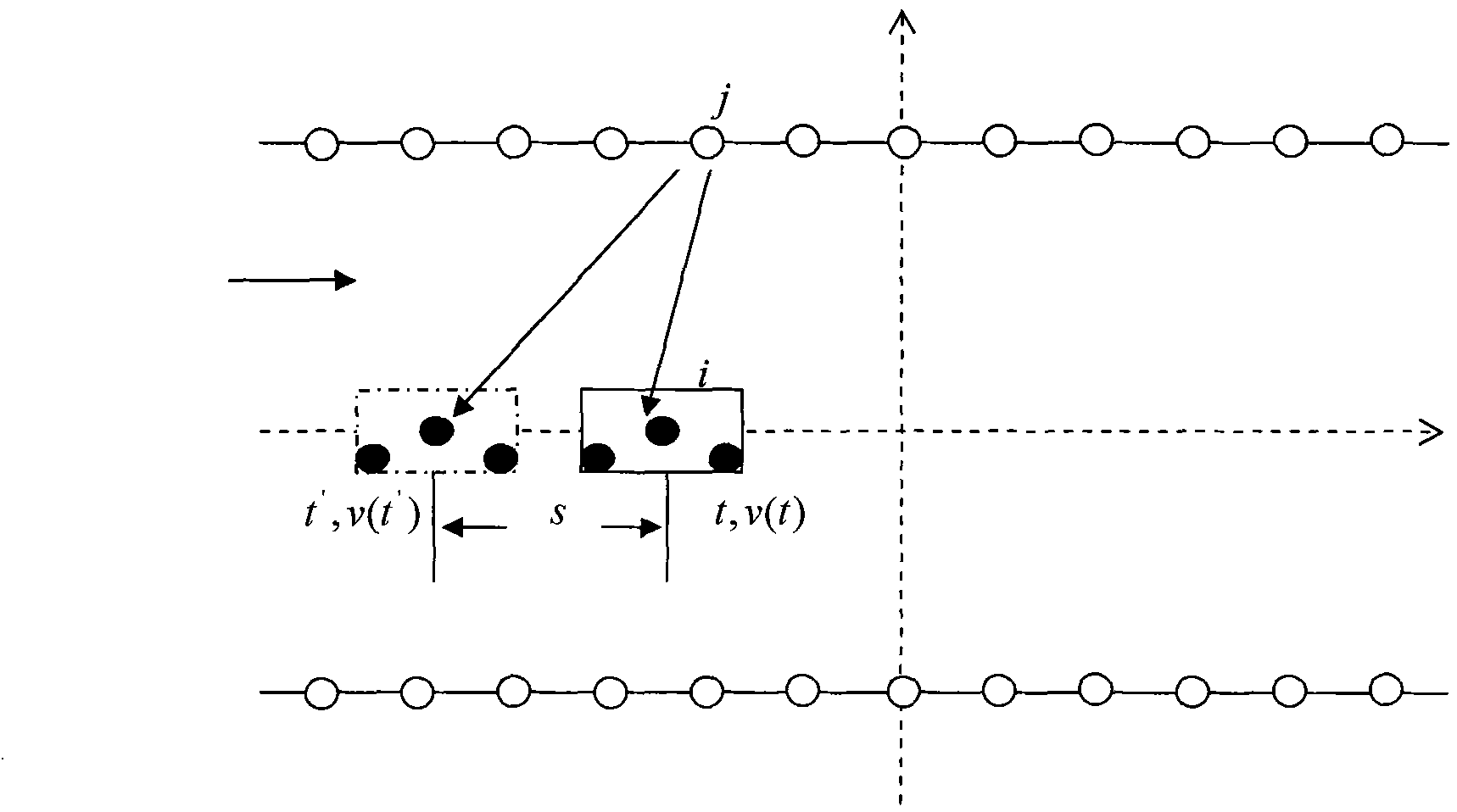

[0032] 1.2 Dynamic description of the exterior noise test of accelerating vehicles

[0033] Information at time t:

[0034] X(t) The spatial position of the vehicle at time t

[0035] v(t) The speed of the vehicle at time t

[0036] rpm(t) The speed of the vehicle at time t

[0037] load(t) The load of the vehicle at time t

[0038] x i ...

Embodiment 2

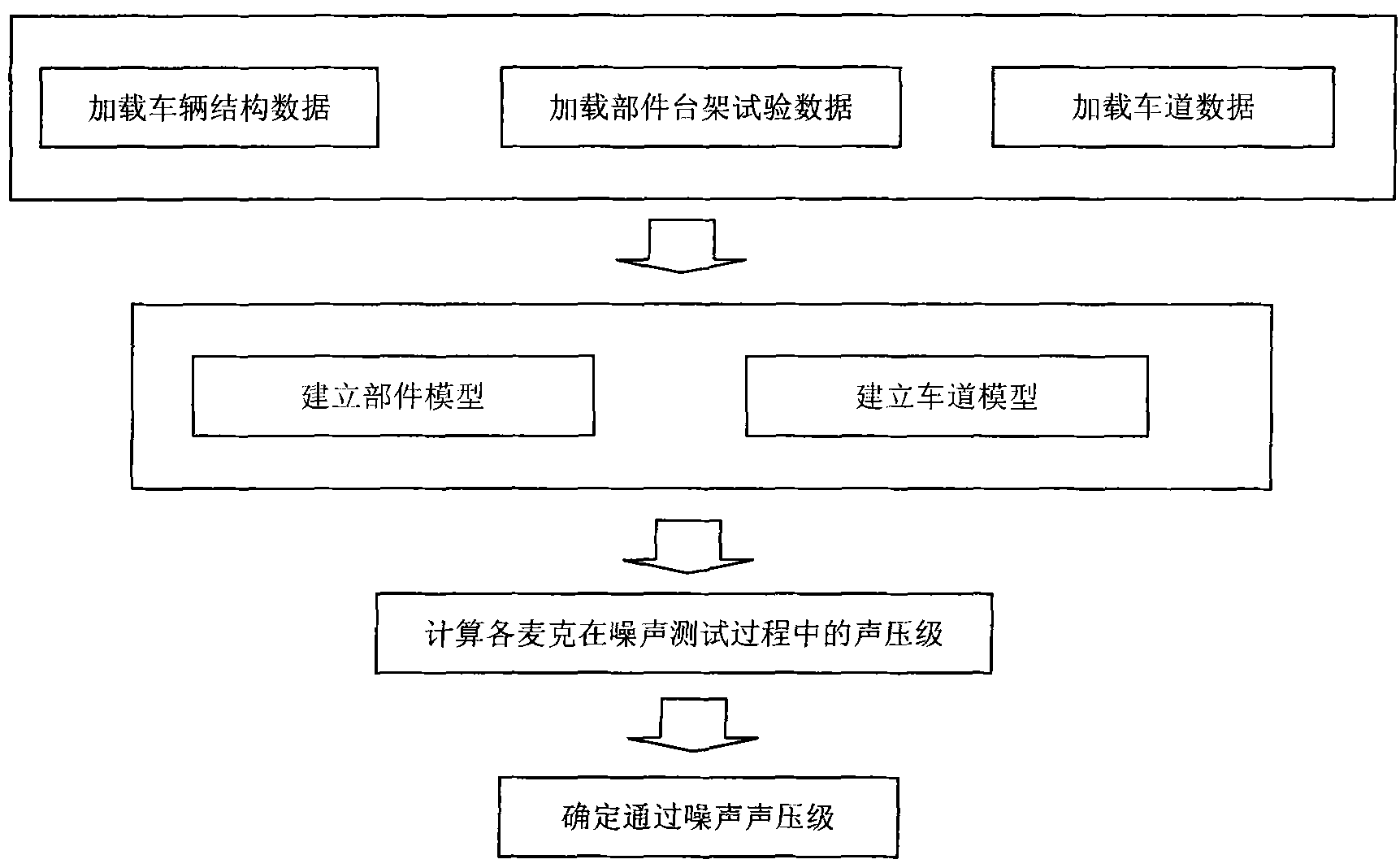

[0055] Such as image 3 Shown is a schematic diagram of the prediction algorithm of the present invention;

[0056] 2.1 Load data

[0057] 2.1.1 Load the vehicle structure data, including the length of the vehicle body and the spatial position of the geometric center of each assembly component relative to the front of the vehicle (see Table 2);

[0058] 2.1.2 Load the component bench test data, that is, the sound pressure level of each assembly component at different speeds (see Table 3-Table 10), the data of each component in Table 3-Table 10 indicates that the engine speed interval is: 1000 , 1500, 2000, 2400, 2500, 2600, 2700, 2800, 2900, 3000, 3100, 3200, 3300, 3400r. / min, the sound pressure level of each component measured by the microphone on the bench test.

[0059] 2.1.3 Load the lane data, load the data according to the test conditions described in ISO362- "Measurement Method for Exterior Noise of Accelerated Vehicles", including the incoming speed, outgoing speed, ...

Embodiment 3

[0082] Such as Figure 4 , 5 Shown is the operation result figure of the present invention;

[0083] in Figure 4 It represents the schematic diagram of the external noise of the simulated accelerating vehicle, Figure 5 Indicates the equivalent sound pressure level of each noise source and its contribution. List the final calculation results in Table 11;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com