Easy-to-strip skeleton type optical cable

A skeleton-type optical cable and skeleton technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of destroying the overall structure of the optical cable, troublesome marking lines, poor skeleton extrusion, etc., and achieve the effects of simple identification, long service life and convenient branching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

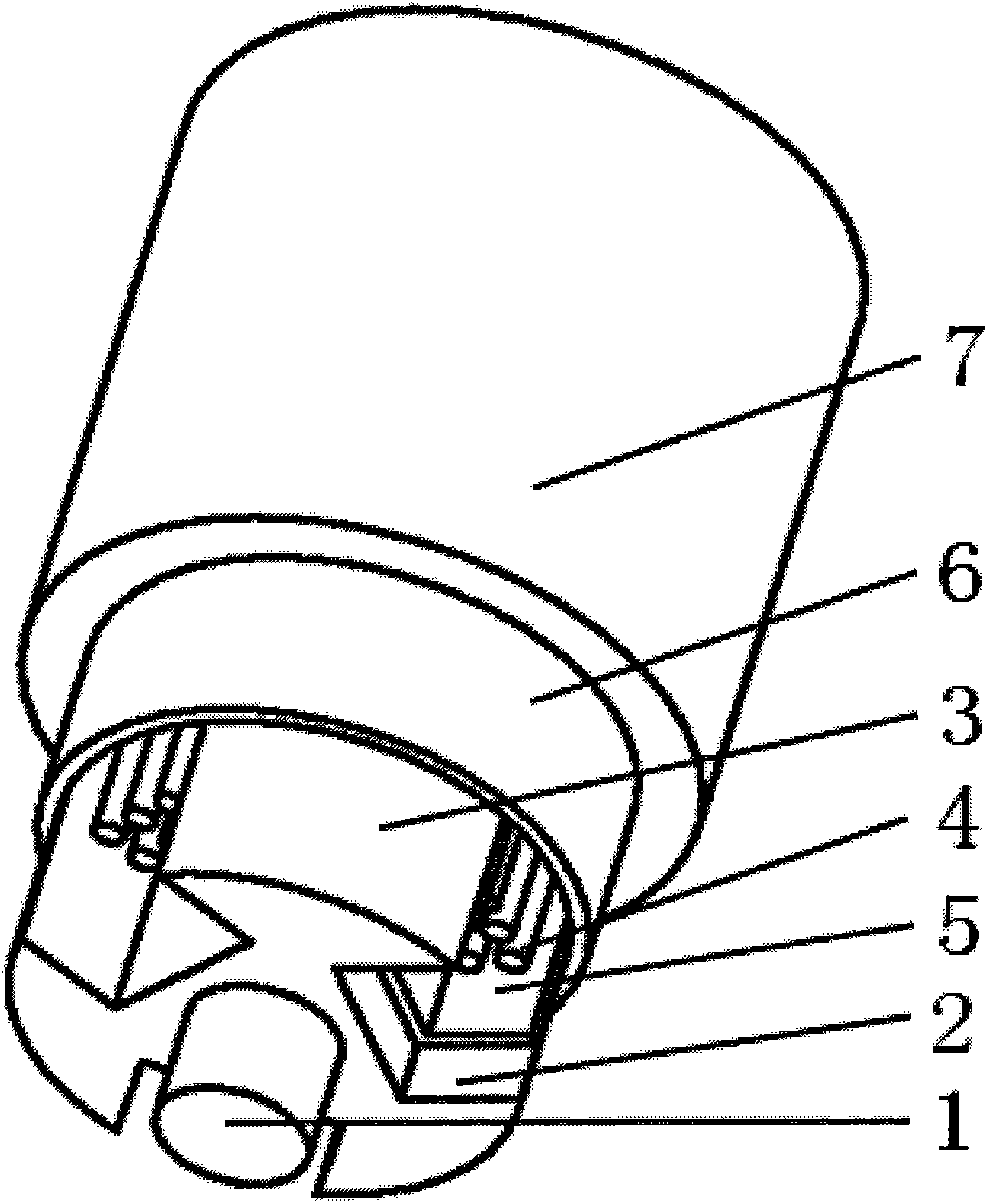

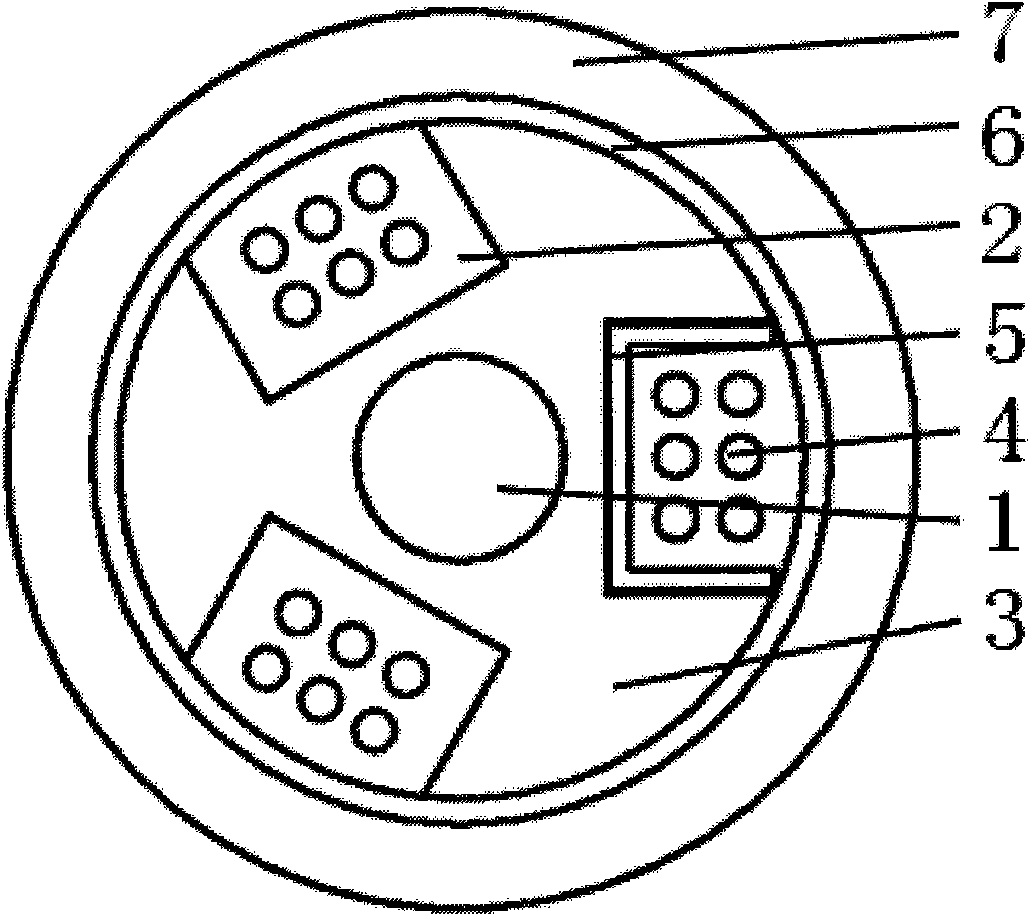

[0025] see figure 1 and figure 2 , an easy-to-peel skeletal optical cable, which includes: a central strength member 1 in the center, a skeleton 3 formed by a cylinder with a skeleton groove 2 surrounding the central strength member, an optical fiber 4 or an optical fiber ribbon located in the skeleton groove 2, Covering the tape layer 6 of the skeleton 3 and the skeleton groove 2 and the outer sheath 7 extruded outside the tape layer; it is characterized in that: in the optical cable, there is a marking tape 5 in the skeleton groove 2; The identification band is conductive; the central reinforcement is non-metallic; there are three skeleton grooves; the central reinforcement is glass fiber reinforced plastic; the skeleton is made of plastic; The outer sheath is low-density polyethylene; the tape layer is a water-blocking tape covered longitudinally; the identification tape contains iron; the identification tape is laid on the bottom and side of the skeleton groove, and the ...

Embodiment 2

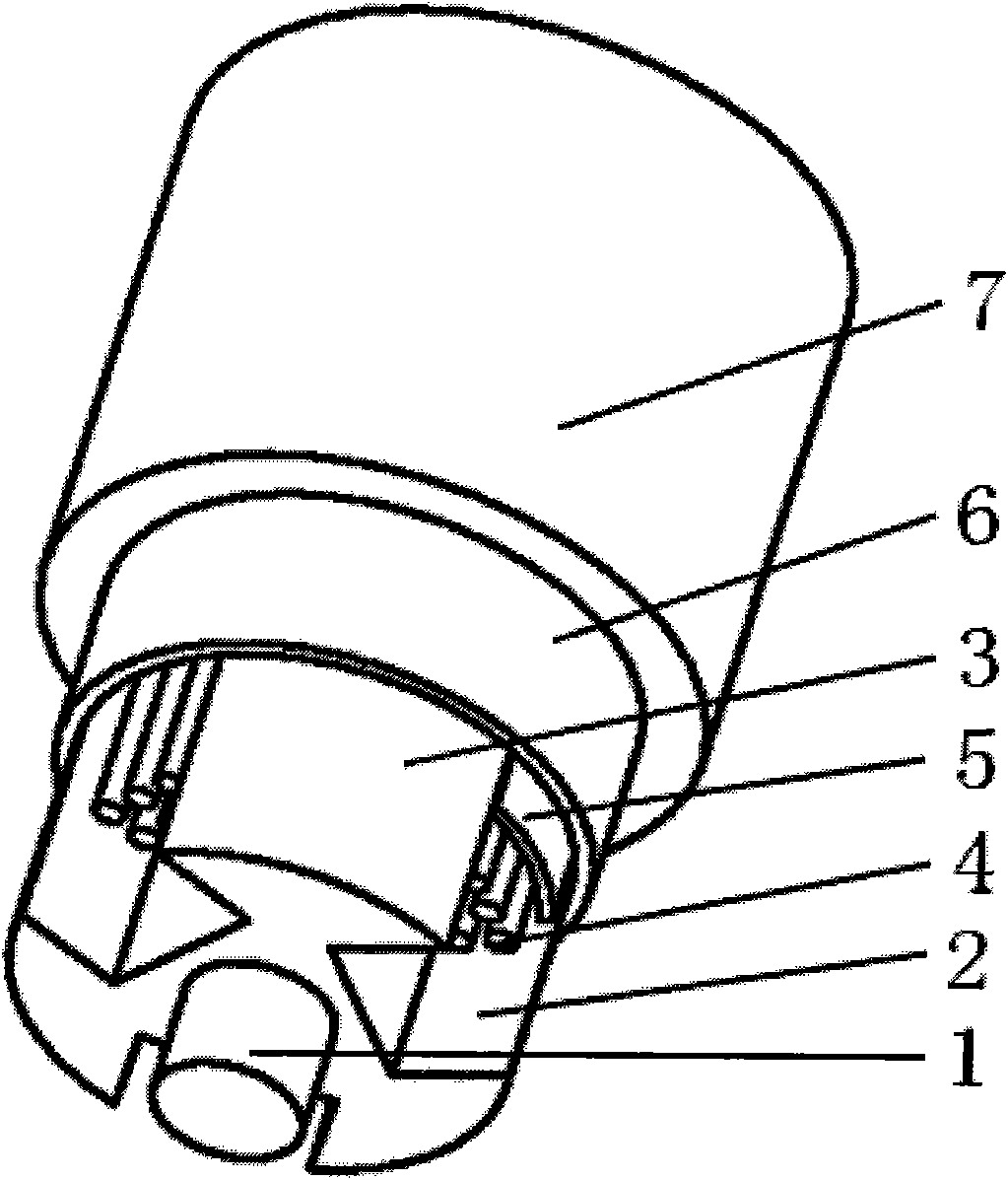

[0026] see image 3 and Figure 4 , an easy-to-peel skeletal optical cable, which includes: a central strength member 1 in the center, a skeleton 3 formed by a cylinder with a skeleton groove 2 surrounding the central strength member, an optical fiber 4 or an optical fiber ribbon located in the skeleton groove 2, Covering the tape layer 6 of the skeleton 3 and the skeleton groove 2 and the outer sheath 7 extruded outside the tape layer; it is characterized in that: in the optical cable, there is a marking tape 5 in the skeleton groove 2; The identification band is conductive; the central reinforcement is non-metallic; there are three skeleton grooves; the central reinforcement is glass fiber reinforced plastic; the skeleton is made of plastic; The outer sheath is low-density polyethylene; the cladding layer is a water-blocking tape covered longitudinally; the identification tape contains iron; the identification tape is located on the top of the skeleton groove and above the ...

Embodiment 3

[0027] see Figure 5 , an easy-to-peel skeletal optical cable, which includes: a central strength member 1 in the center, a skeleton 3 formed by a cylinder with a skeleton groove 2 surrounding the central strength member, an optical fiber 4 or an optical fiber ribbon located in the skeleton groove 2, The tape layer 6 covering the skeleton 3 and the skeleton groove 2 and the outer sheath 7 extruded outside the tape layer; it is characterized in that: in the optical cable, there are three skeleton grooves 2 with identification tapes 5; The identification band is conductive; the central reinforcement is non-metallic; there are three skeleton grooves; the central reinforcement is glass fiber reinforced plastic; the skeleton is made of plastic; The outer sheath is low-density polyethylene; the cladding layer is a water-blocking tape covered longitudinally; the identification tape contains iron; the identification tape is located on the top of the skeleton groove and above the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com