Aluminum alloy foil

A kind of aluminum alloy foil, aluminum alloy technology, applied in the field of aluminum alloy foil

Active Publication Date: 2010-08-18

TOYO ALUMINIUM KK +1

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at this time, since hard and coarse intermetallic compounds of the Al-Cr-Mn system are crystallized on the aluminum foil, when the container is formed from the aluminum foil, the possibility of defects such as pinholes may occur. In other words, there is room for improvement

In this way, there are problems or room for improvement in any of the above-mentioned ones. If it is possible to design a single aluminum alloy foil with a specific resistance value above a certain value, which is excellent in formability and corrosion resistance, it is suitable for use in electromagnetic cookers. The aluminum alloy foil forming container for heating and cooking can solve all the above problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

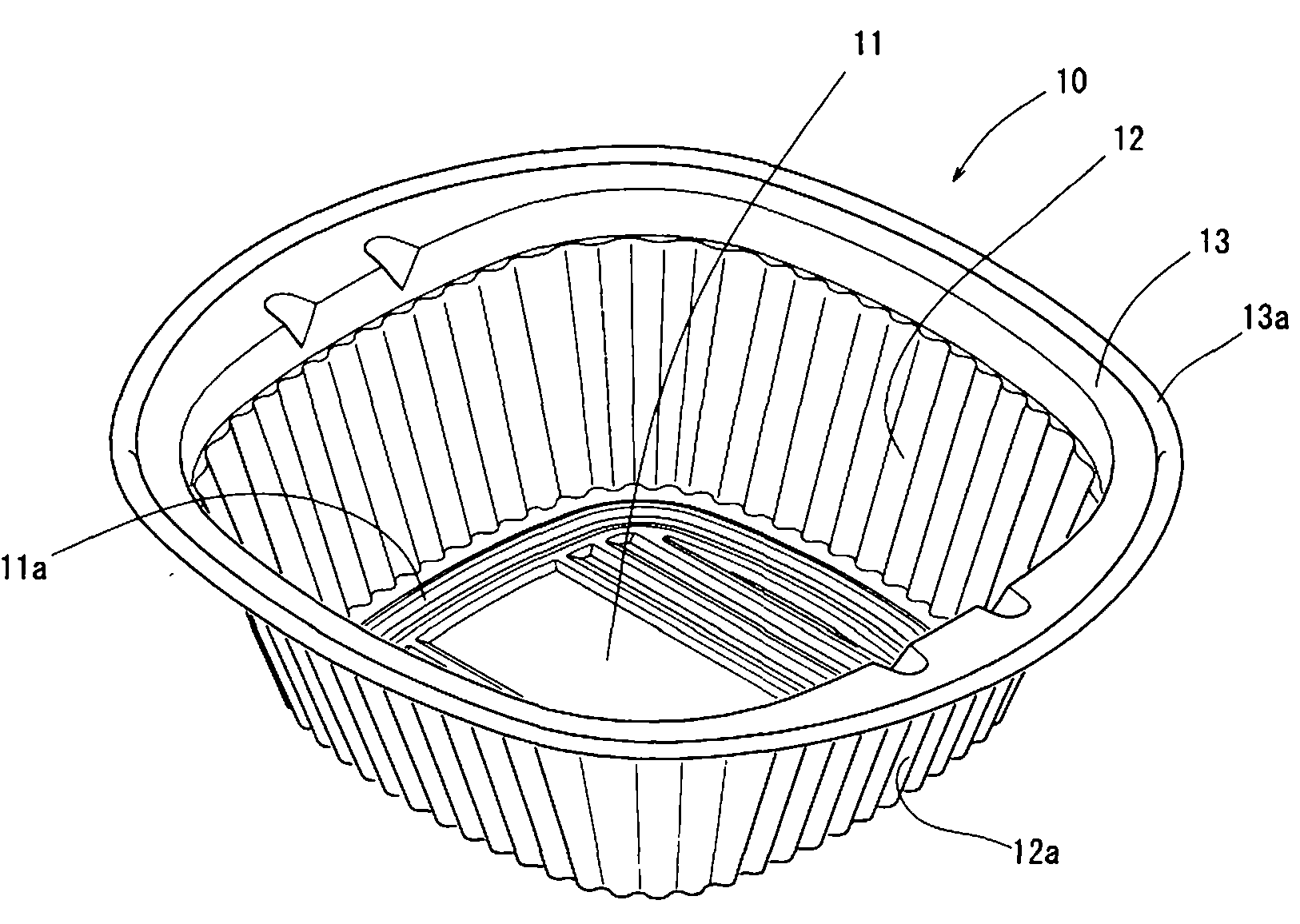

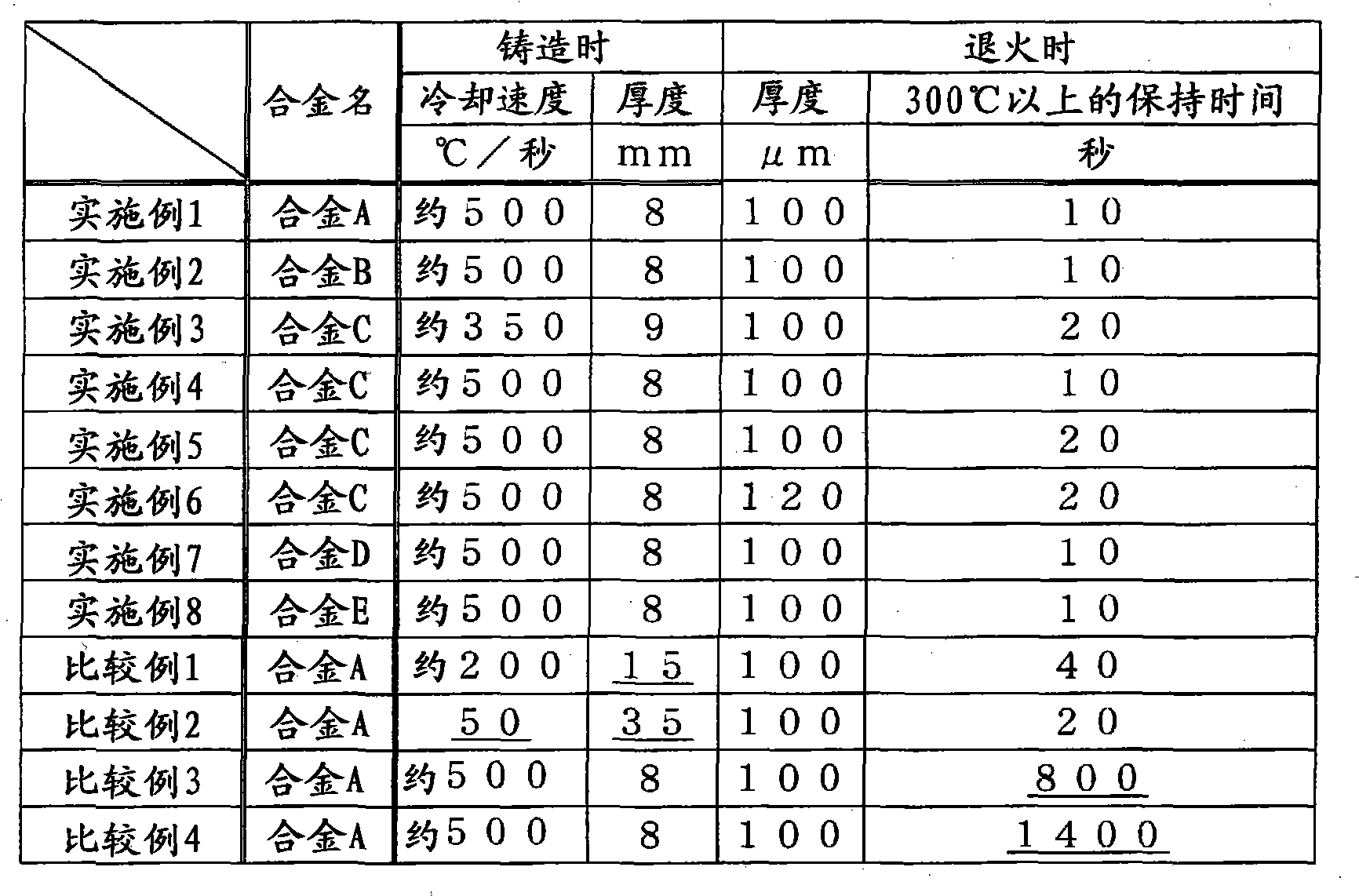

An aluminum alloy foil formed container is provided which is formed of a aluminum alloy foil single body having at least a specified electric specific resistance, is excellent in formability and corrosion resistance, and is suitable for cooking by an electromagnetic cooker. Molten aluminum alloy is cast to a thickness of up to 10mm at a cooling rate of at least 100 DEG C / second, then the cast product is cold-rolled to a thickness of 50-300[mu]m, then the rolled product is annealed at at least 300 DEG C for a heating retaining time of up to 10 minutes to form an aluminum alloy foil, 50-200[mu]m in thickness and at least 6.0 [mu]Omega cm in electric specific resistance, and it is press-formed to obtain an aluminum alloy foil formed container (10) having a bottom wall (11), a peripheral wall (12) and a flange (13). This container (10) is excellent in formability (especially pinhole resistance) and corrosion resistance, and has an electric resistance suitable for cooking by an electromagnetic cooker.

Description

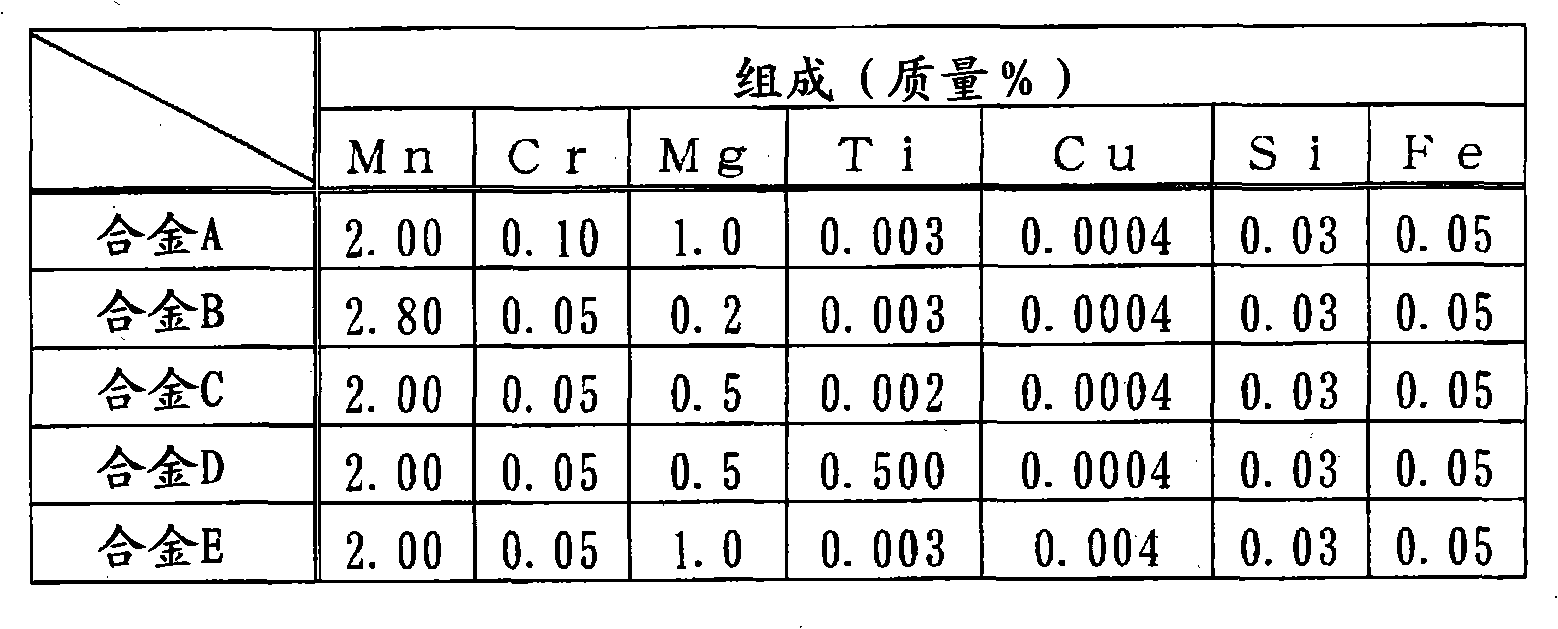

technical field The present invention relates to: a food package suitable for heating and cooking by an electromagnetic cooker, an aluminum alloy foil-shaped container used as a container for the food package, and a raw material of the container with a specific thickness obtained by a specific manufacturing method. Aluminum alloy foil with specific resistance value and resistivity value, and the manufacturing method of the aluminum alloy foil. Background technique The food package made of noodles, hot pot and other food in the aluminum foil forming container can be eaten directly by heating and cooking without transferring to other containers, and the container can be thrown away after eating, so it is very convenient. It is used in convenience stores. Sales and so on are widely popularized. In the past, these food packages were generally heated and cooked directly by a gas stove or the like. However, in recent years, electromagnetic cookers have been rapidly popularized i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C21/00A47J27/00A47J36/02B65D81/34C22F1/04C22F1/00

CPCB65D2581/3487A47J36/02B65D1/34C22F1/04B65D2581/3472B65D81/3453C22C21/00

Inventor 吕明哲多田裕志左近贵浩

Owner TOYO ALUMINIUM KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com