Multi-zone separately controlled plasma sterilizer

A technology of plasma and sterilizer, which is applied in the direction of sanitary equipment for toilets, water supply devices, buildings, etc., can solve the problem that plasma sterilizers cannot meet large-scale applications, and solve the problem that it is not suitable for medical and scientific research purposes , Solve the effect of excessive load, flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

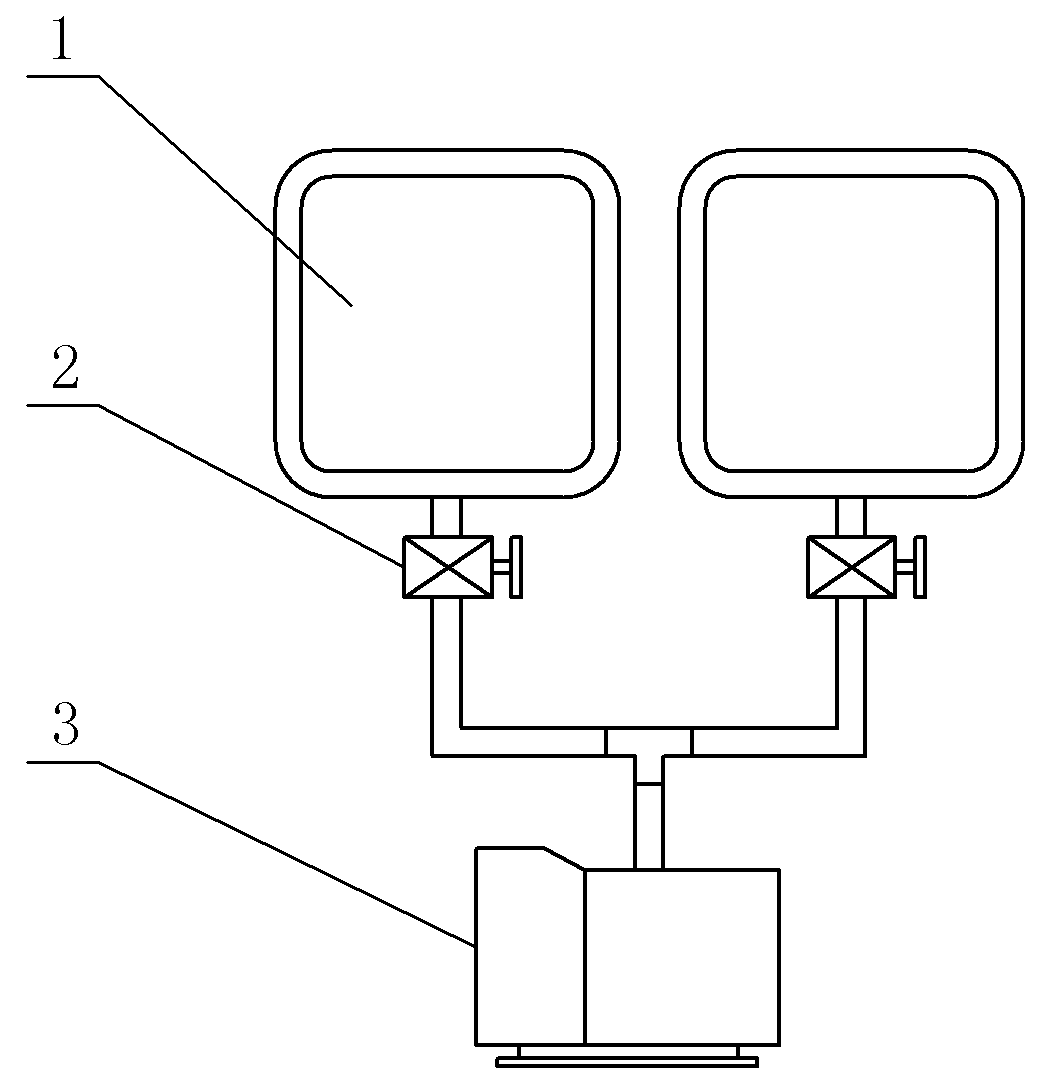

[0036] As shown in Figure 1: the number of inner chambers 1 is two, and the two inner chambers 1 are respectively connected to the vacuum system 3 through pipelines. The vacuum system 3 can be a vacuum pump or a vacuum pump group. Control valves 2 are provided on the connecting pipelines between the systems 3 .

[0037] When this embodiment is used, as required, the two inner chambers 1 and the vacuum system 3 can be controlled by synchronous sub-control, or by asynchronous sub-control.

Embodiment 2

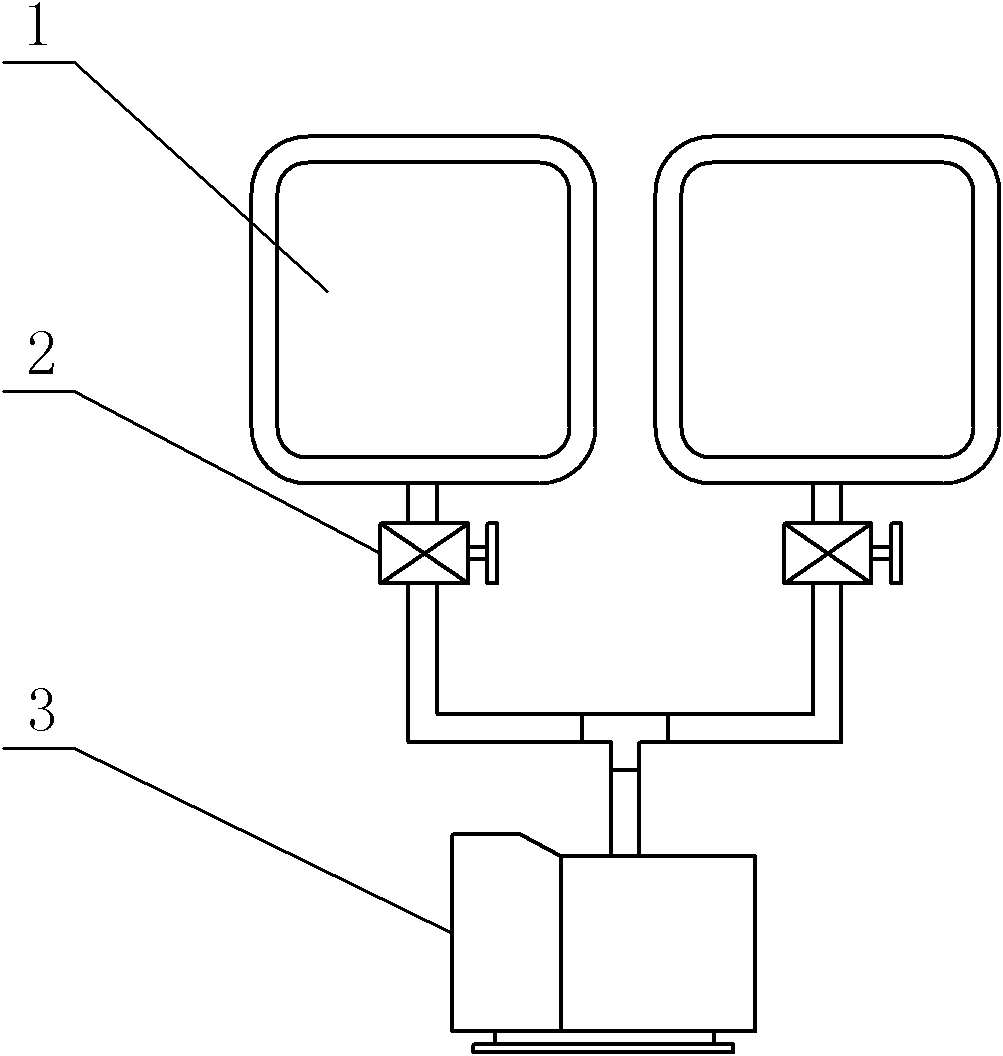

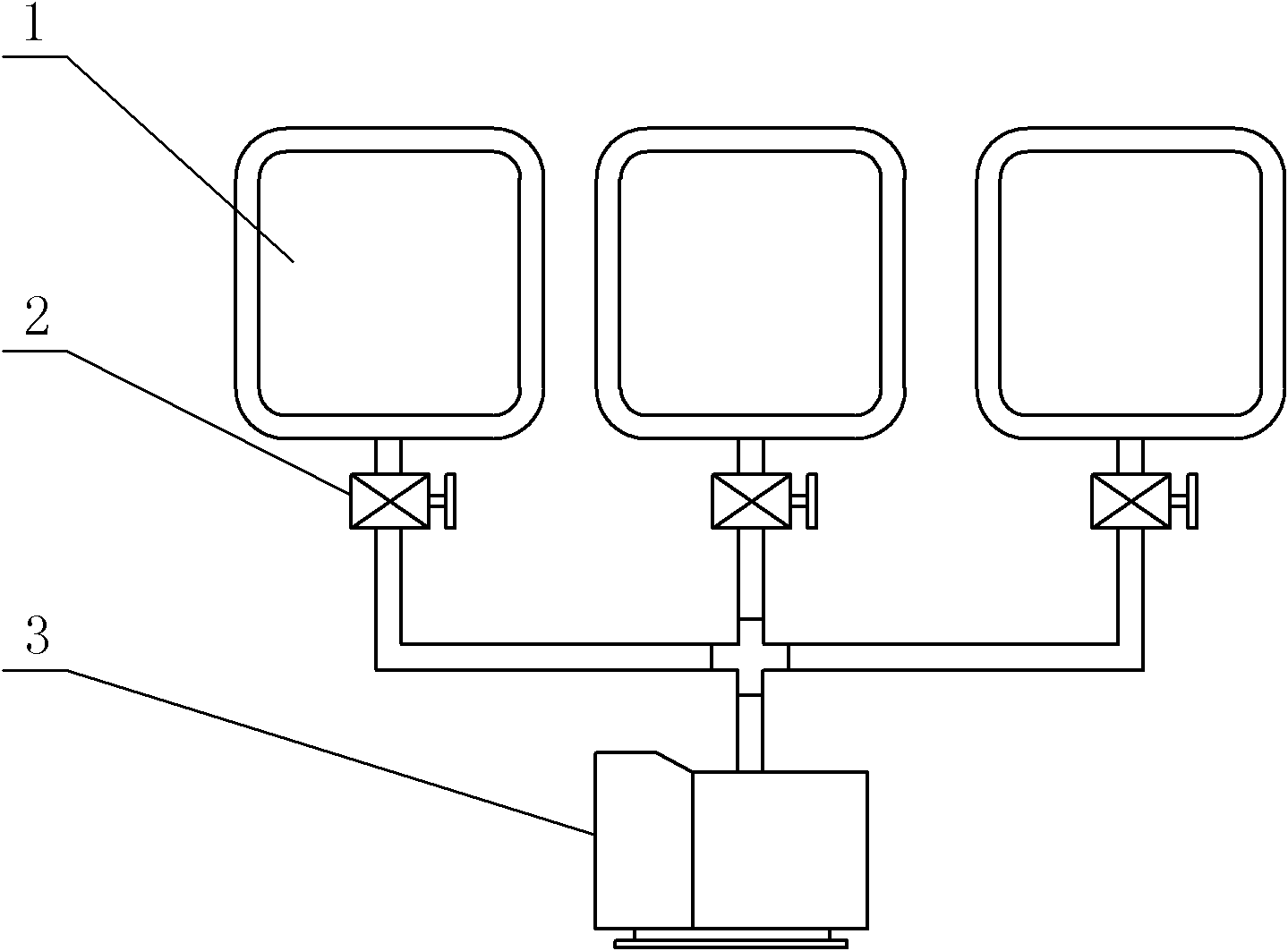

[0039] As shown in Figure 2: the number of inner chambers 1 is three, and the three inner chambers 1 are respectively connected to the vacuum system 3 through pipelines. The vacuum system 3 can be a vacuum pump or a vacuum pump group. Control valves 2 are provided on the connecting pipelines between the systems 3 .

[0040] As shown in Figure 3; the three inner chambers 1 and the vacuum system 3 are controlled by means of asynchronous sub-control.

[0041] As shown in Figure 4: the three inner chambers 1 and the vacuum system 3 are controlled by means of synchronous sub-control.

Embodiment 3

[0043] As shown in Figure 5: the number of inner chambers 1 is six, and the six inner chambers 1 are respectively connected to the vacuum system 3 through pipelines. The vacuum system 3 can be a vacuum pump or a vacuum pump group, and the six inner chambers 1 are connected to the vacuum system Control valves 2 are provided on the connecting pipelines between the systems 3 .

[0044] As shown in Figure 6: the six inner chambers 1 are divided into three inner chamber groups in pairs, and the two inner chambers 1 of each inner chamber group adopt synchronous separate control, while the three inner chamber groups adopt Asynchronous sub-control.

[0045] Compared with Embodiment 1 and Embodiment 2, the capacity expansion of this embodiment is easier, but the sterilization speed will be slightly affected, and generally speaking, the capacity increase is larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com