Full-automatic transport vehicle carriage device

A transport vehicle, fully automatic technology, applied to vehicles with wheels, vehicles with chains/belts, etc., can solve the difficulty of loading large-quality goods, hinder the efficiency of modern manufacturing, and restrict the development of the logistics industry, etc. problems, to achieve the effect of improving the quality of transportation, improving the efficiency of loading and unloading, and improving the speed of logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

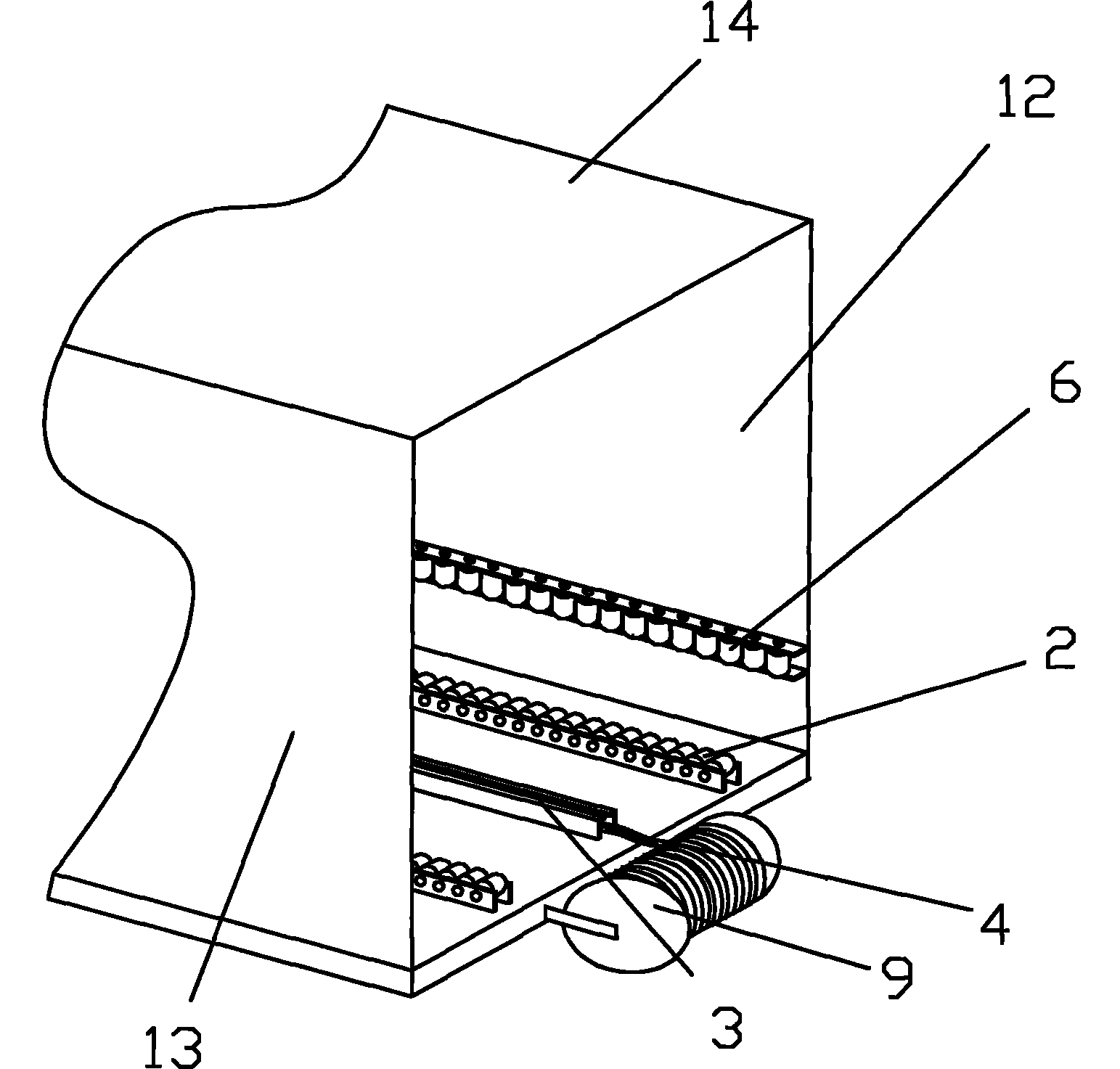

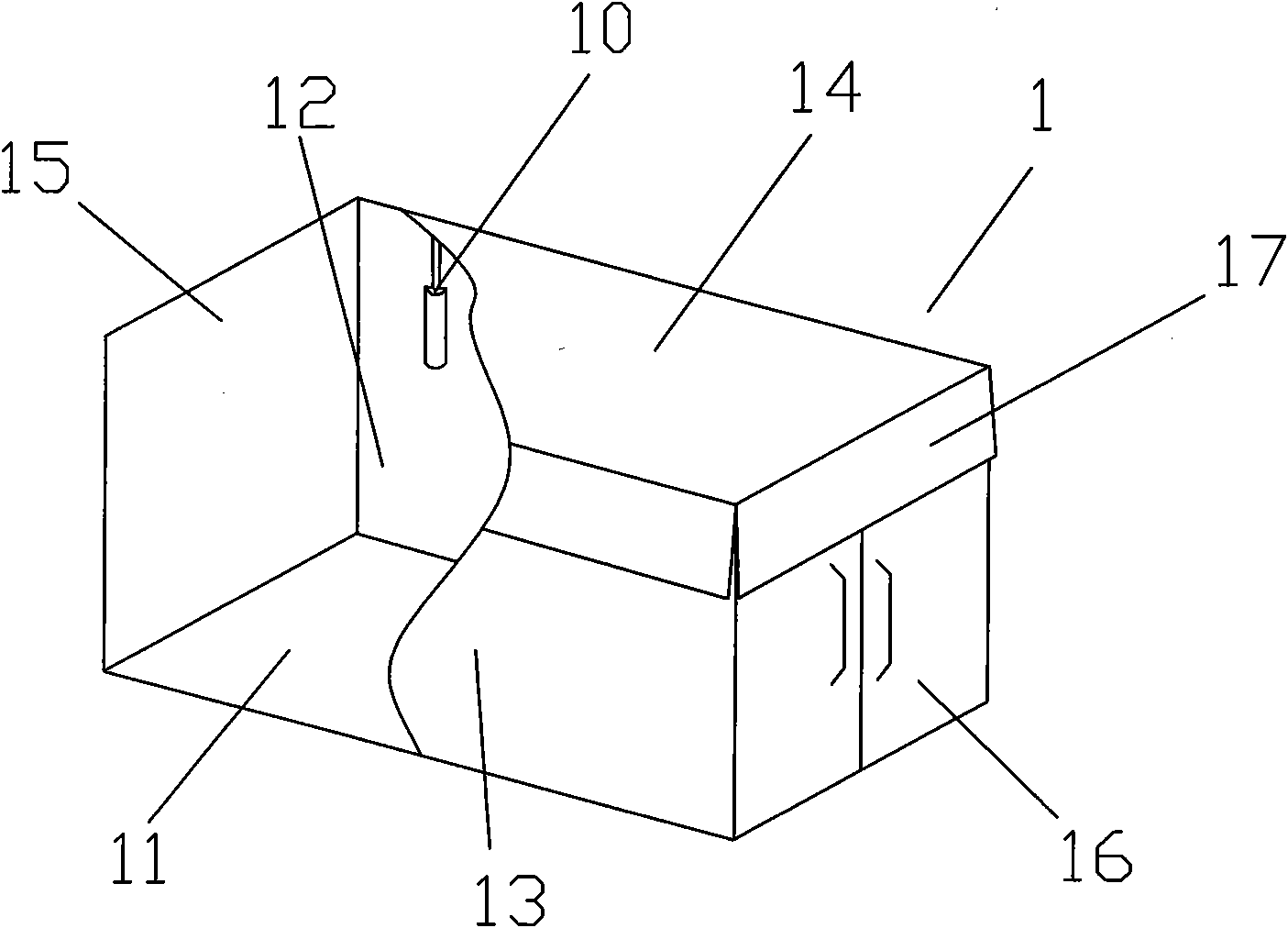

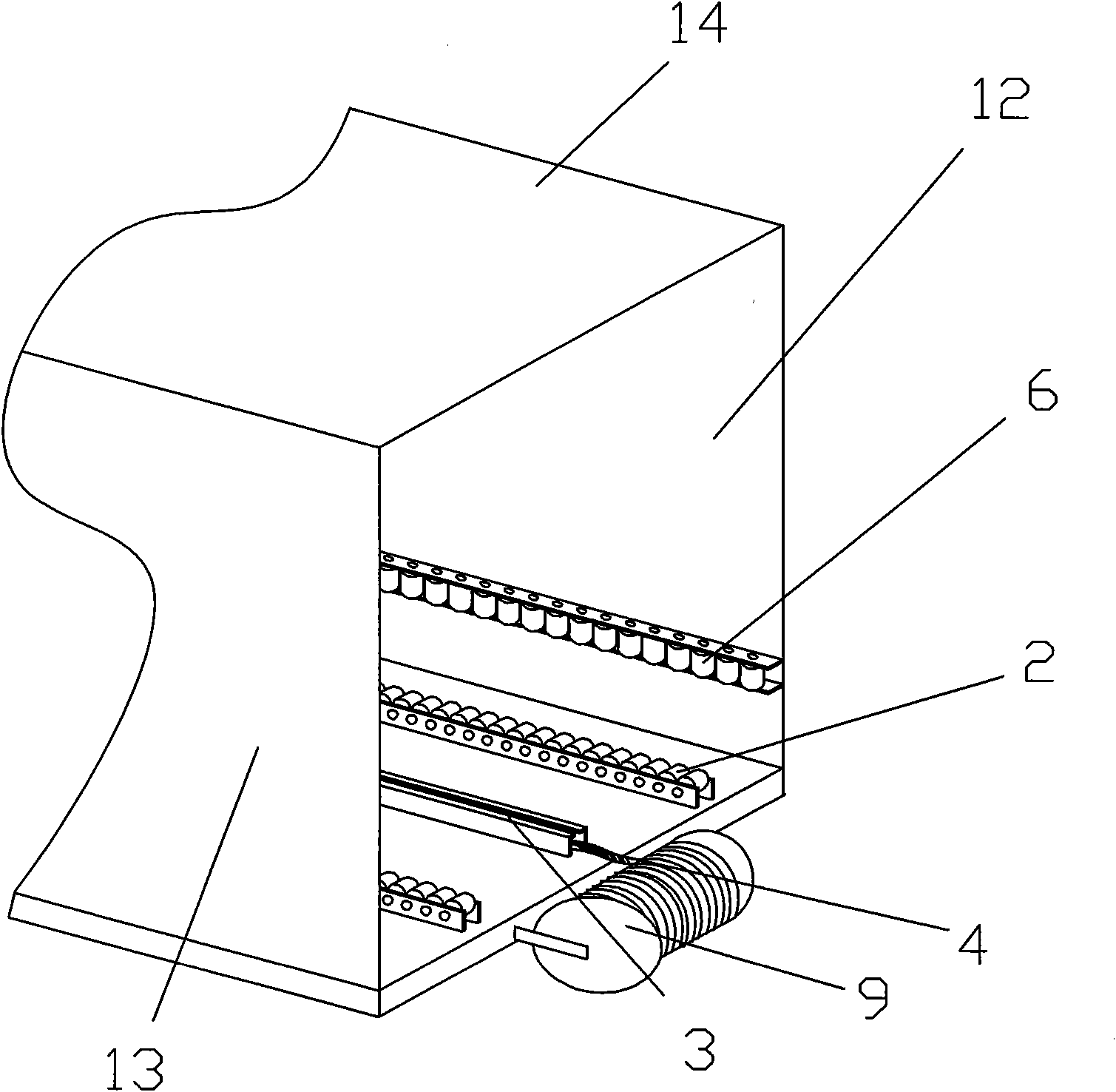

[0018] With reference to Fig. 1, Fig. 2 and Fig. 3, a kind of full-automatic transportation vehicle carriage device comprises the carriage 1 that is made up of base plate 11, side wall 12,13, top cover 14, front cover 15 and openable back cover 16, The base plate 11 of the compartment 1 is provided with several groups of rollers 2, and the base plate 11 is also provided with a chute 3 whose height is not higher than the rollers 2, and a cable 4 is arranged in the chute, and the cable 4 is located on the vehicle. One end inside is connected with a transverse baffle 5 that can pull out the goods, and the other end of the cable 4 is connected to a hoist 9 located outside the compartment 1, and the transverse baffle 5 can be pulled along the chute under the pull of the cable 4. 3 movement, the top cover 14 is sleeved on the box frame composed of the side walls 12, 13, front cover 15 and rear cover 16, and a hydraulic cylinder 10 is also installed on the side walls 12, 13, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com