Preparation method of double-mesopore silicon dioxide transparent gel monolith

A silica, double mesoporous technology, applied in crack-free, transparent silica gel monolith and its rapid preparation, double mesoporous silica transparent gel monolith and its preparation, large-scale field, can Solve the problems of industrial production of unfavorable materials, complex operation steps, low preparation efficiency, etc., to achieve the effect of shortening preparation time, simplifying preparation procedures, and improving preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

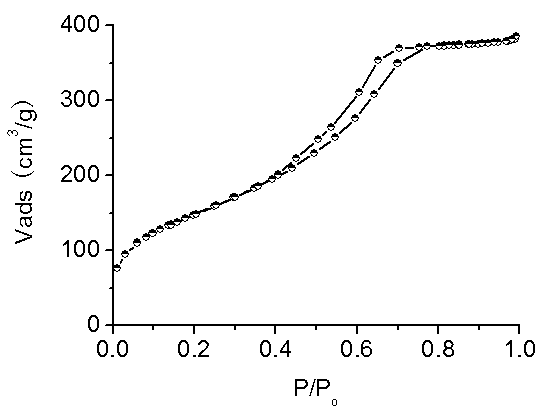

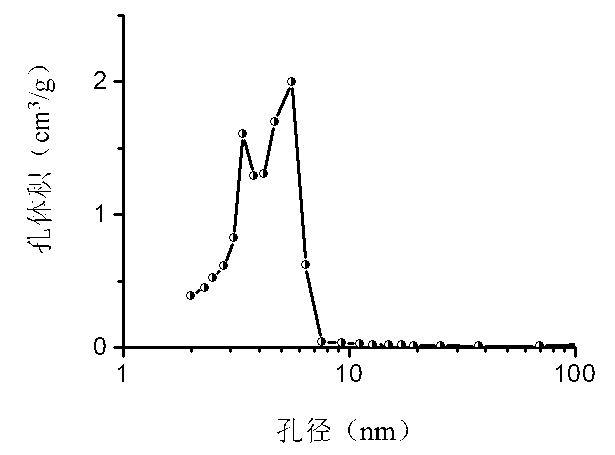

[0028] 1 g of P123, 2 g of TMB, 0.18 g of water, 0.2 g of 1M hydrochloric acid and 2.08 g of TEOS were mixed and stirred at room temperature for 30 minutes to form a homogeneous sol. The prepared sol was moved into a container with a certain shape, sealed, and left to stand at a constant temperature at 45° C. for 1 hour, and then left to stand at 45° C. for 6.5 hours to make the system gel. Then seal the container again and leave it to age at a constant temperature of 45°C for 1 day, and finally directly dry it in the open at 45°C, and obtain a complete double mesoporous silica transparent gel monolith after 48 hours. Then the temperature was raised to 550°C at a rate of 2°C / min and calcined for 6 hours to completely remove the surfactant template to obtain an ordered double mesoporous silica gel monolithic material, which was tested by XRD, TEM, N 2 Analytical tests such as isothermal adsorption show that the obtained material has a combination of cylindrical primary mesopore...

Embodiment approach 2

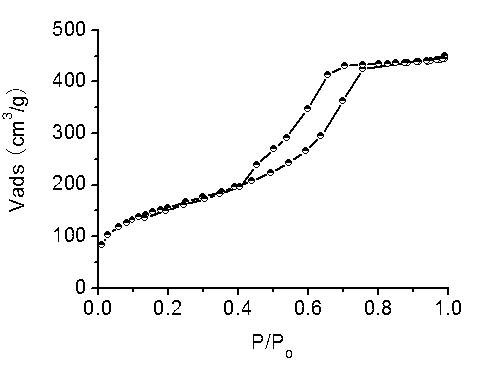

[0030]1.458 g of P123, 0.18 g of water, 0.2 g of 1M hydrochloric acid and 2.08 g of TEOS were mixed and stirred at room temperature for 30 minutes to form a homogeneous sol. The prepared sol was moved into a container with a certain shape and sealed, and then stood at a constant temperature at 45°C for 1 hour, and then left the container open at 45°C for 7.5 hours to gel the system. Then seal the container again and leave it to age at a constant temperature of 45°C for 1 day, and finally dry it in the open at 45°C. After 48 hours, a complete double mesoporous silica gel monolith is obtained, and then at 2°C / min The temperature was raised to 550°C at a high rate and calcined for 6 hours to completely remove the surfactant template to obtain an ordered double mesoporous silica gel monolithic material, which was tested by XRD, TEM, N 2 Analytical tests such as isothermal adsorption show that the obtained material has a combination of cylindrical primary mesopores and worm-shaped ...

Embodiment approach 3

[0032] 1.458 g of P123, 0.18 g of water, 0.2 g of 1M hydrochloric acid and 2.08 g of TEOS were mixed and stirred at room temperature for 30 minutes to form a homogeneous sol. The prepared sol was moved into a container with a certain shape, sealed, and left to stand at a constant temperature of 60° C. for 1 hour, and then left to stand at 60° C. for 5.5 hours to make the system gel. Then seal the container again and leave it to age at a constant temperature of 60°C for 1 day, and finally directly dry it in the open at 60°C, and obtain a complete double mesoporous silica transparent gel monolith after 40 hours, and the others are the same as in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com