Control method of construction quality of deep mixing piles based on energy consumption monitoring

A technology for deep mixing piles and construction quality, applied in the field of construction engineering, can solve problems such as waste of resources, difference in construction quality, and poor rationality, and achieve the effect of accurate construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

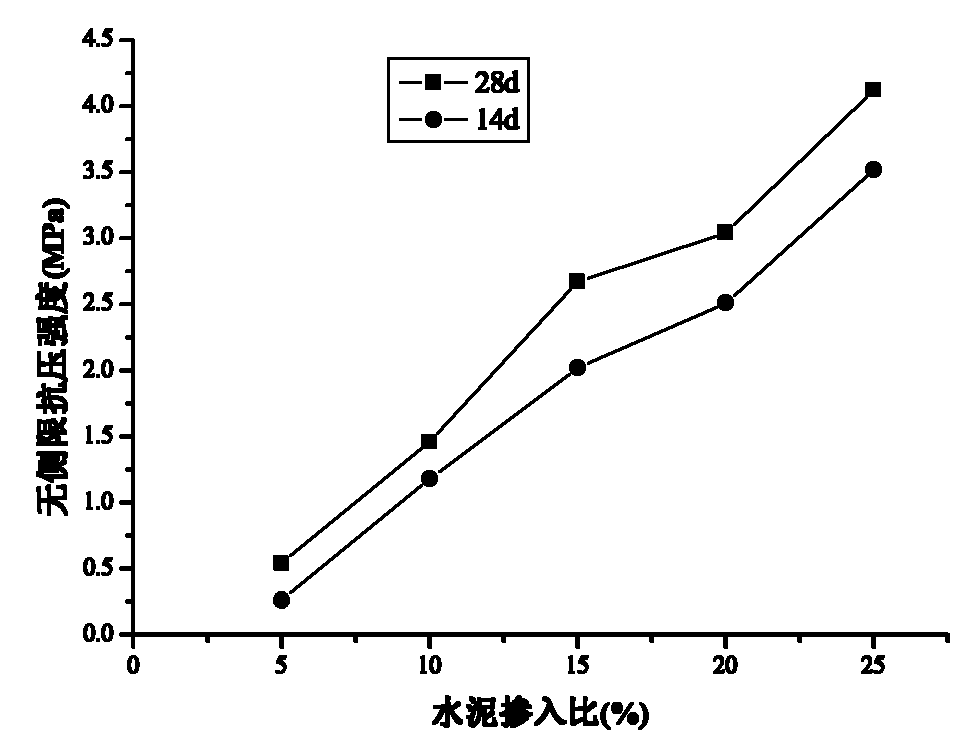

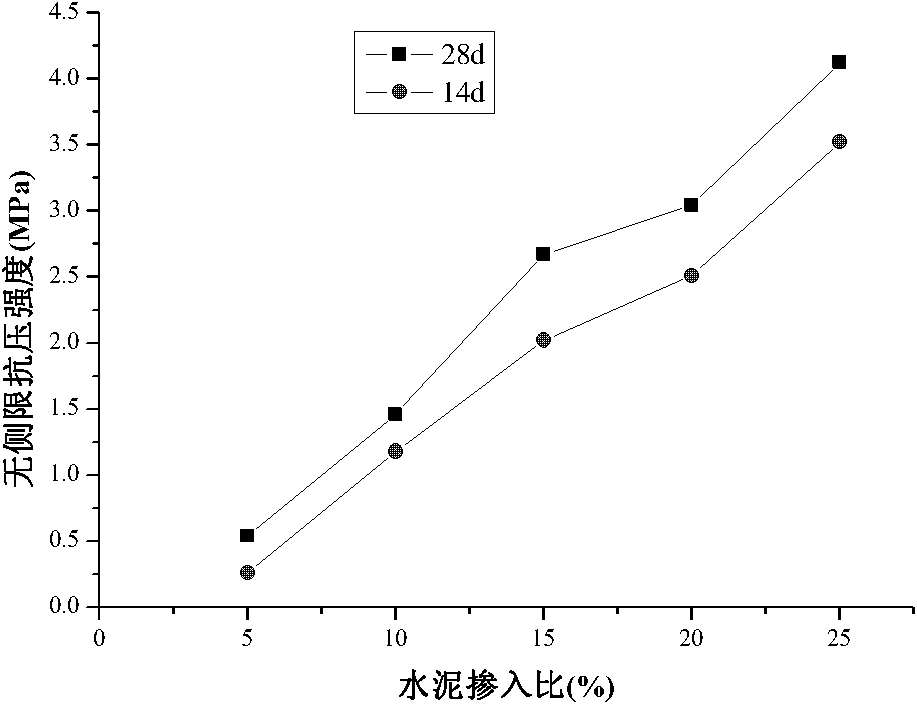

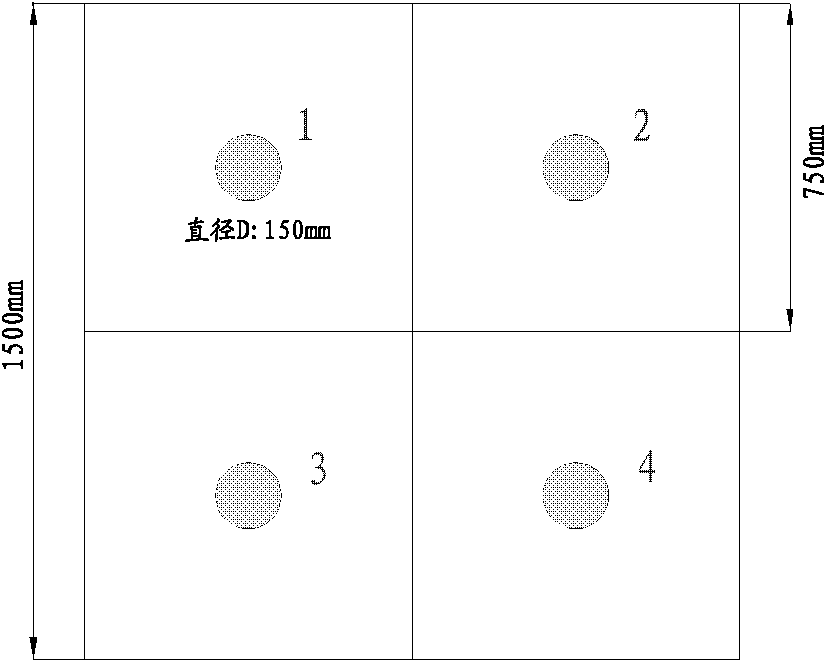

[0031] As shown in Figure 1 and Figure 2, the following steps in this embodiment are carried out:

[0032] (1) Clarify the site geological conditions: the uppermost layer (0.0-0.6m) is an unsaturated soil layer formed by weathering; the lower layer (0.6-13.5m) is a clay layer, which is blue-gray; the lower layer is a sand layer , that is, the upper deep layer of clay and the lower part of sandstone. The water content of the soil samples taken is between 90% and 150%, the clay content is 60%, the silt content is 35%, and the sand content is 5%.

[0033] (2) Carry out indoor mix ratio test, and make test pieces by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com