Two-dimensional plane air-floatation zero-gravity cradle

An air-floating guide, two-dimensional plane technology, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve problems such as inability to adapt to high-precision occasions, and achieve the effect of avoiding additional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

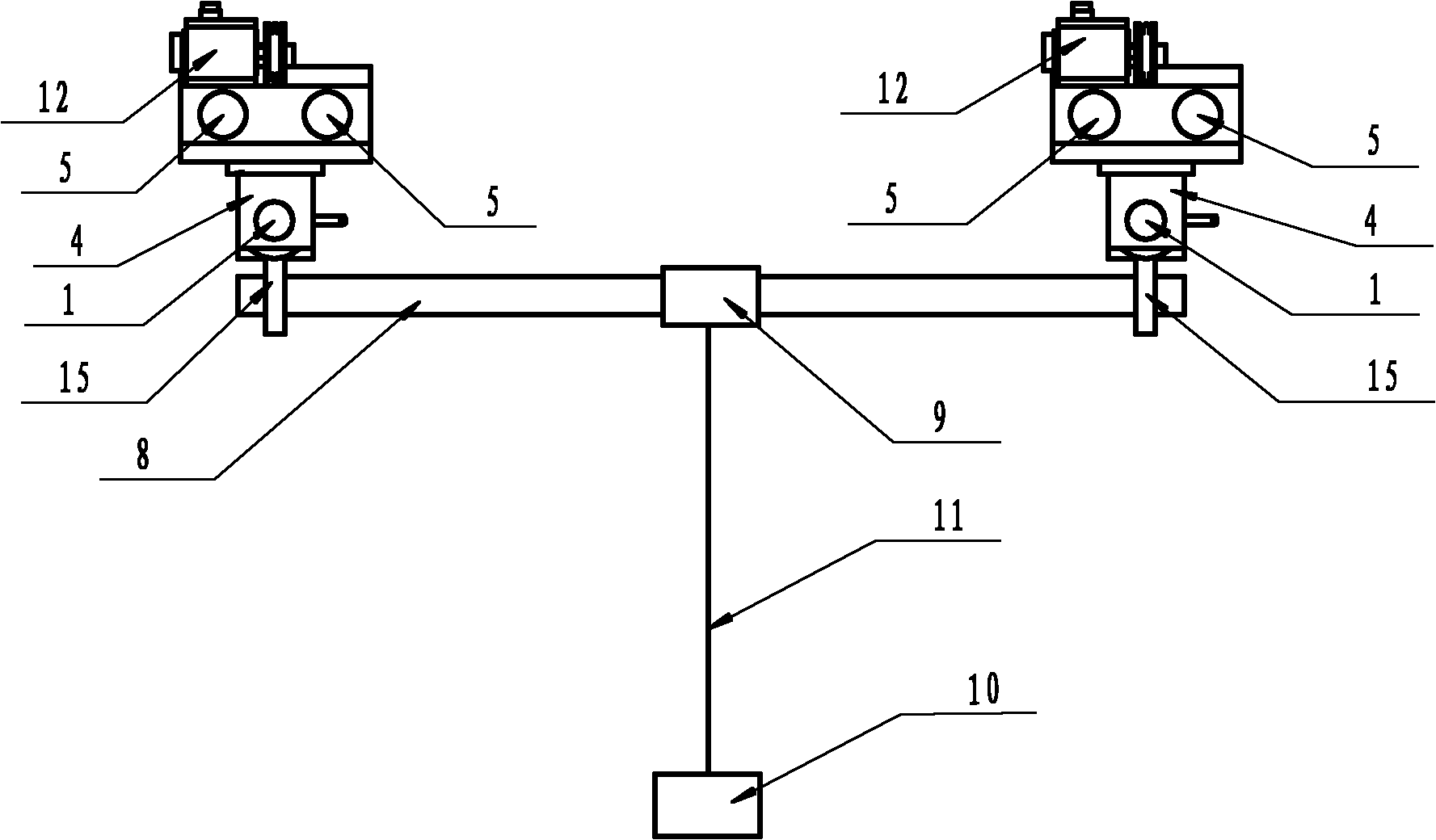

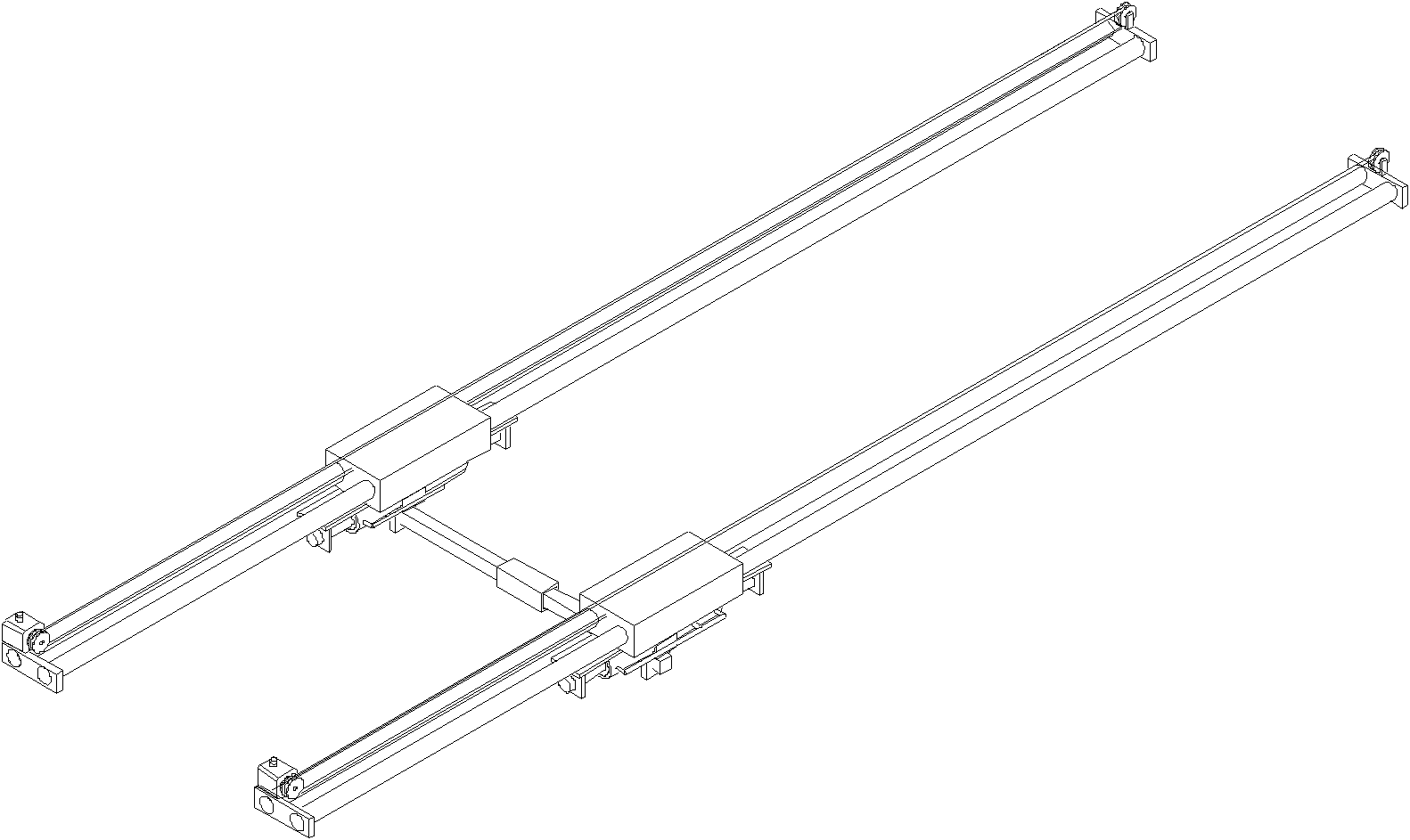

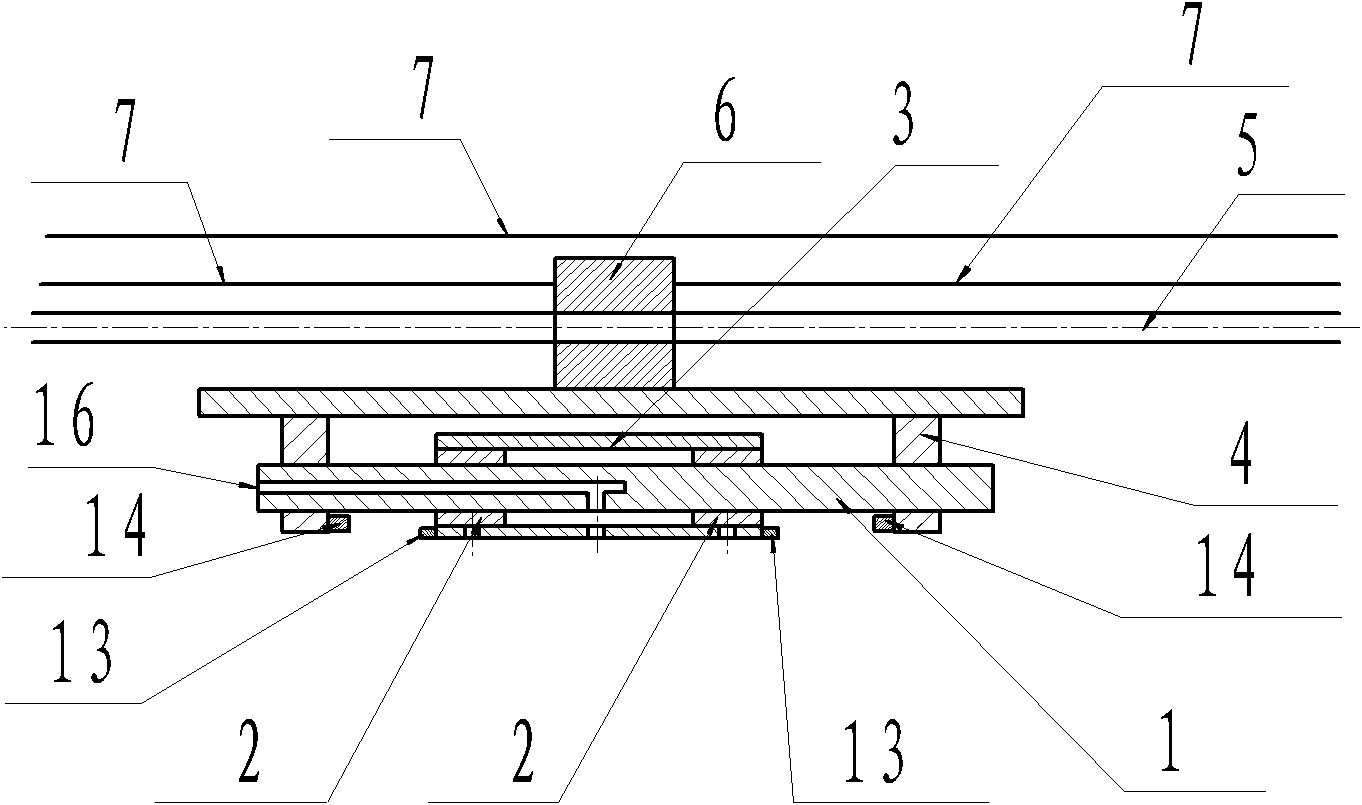

[0024] Referring to Figures 1 to 3, a zero-gravity hanger for a two-dimensional plane air-floating guide rail includes two long-distance air-floating linear guide rails, a Y-axis air-floating shaft, a Y-axis air-floating sleeve, and a suspension rope. The floating linear guideway includes an X-axis air bearing shaft 1, an X-axis air bearing sleeve 2, and a long-distance linear guide rail 5 for providing support and guidance for long-distance movement. The X-axis air bearing sleeve 2 is set on the X-axis air bearing On the floating shaft 1, there are at least two X-axis air bearing sleeves 2, and the X-axis air bearing sleeves 2 are all sealed and connected with the air storage sleeve 3, and a slider 6 is slidably installed on the long-distance linear guide rail 5 , the slider 6 is in transmission connection with the driving mechanism, the slider 6 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com