Air inlet experimental facility capable of carrying out measurement on the same model and operating method thereof

An experimental device and air inlet technology, applied in the field of air inlet experiment, can solve the problem of not being able to know the real resistance of the air inlet

Inactive Publication Date: 2010-08-25

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF2 Cites 55 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention can solve the problem that the real resistance of the air inlet cannot be known during the current aircraft design, and can be used for comparative analysis of the resistance characteristics of different air inlet schemes, so as to obtain the real thrust resistance characteristics of the aircraft

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

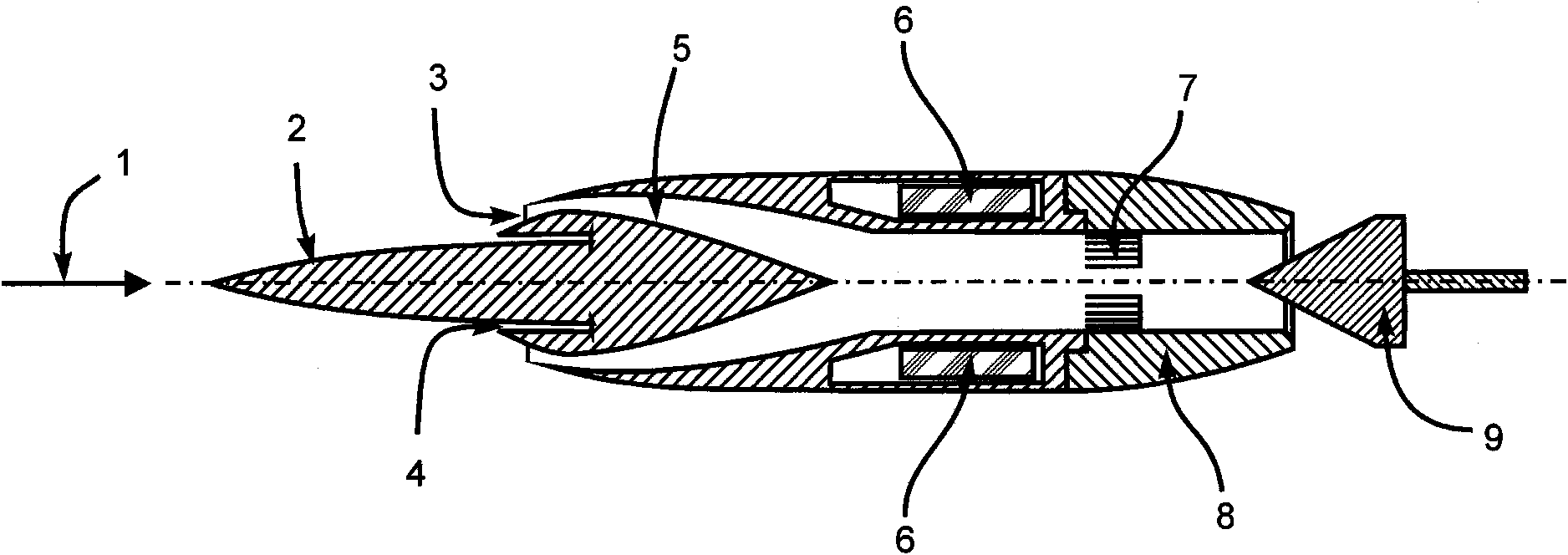

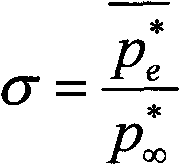

The invention provides an air inlet experimental facility capable of carrying out measurement on the same model and an operating method thereof, relating to the subsonic velocity and supersonic velocity technical field. The air plane body of the invention is provided with an air inlet, a boundary layer separation channel is arranged on the air plane body close to the air inlet, a built-in case type six component strain balance is arranged on the air plane body at the inner channel of the air inlet, the inner wall of the air plane body at the air plane body measuring section is respectively and uniformly distributed with air inlet exit total pressure measuring rakes and static vents, the front end of the total pressure measuring rake and the static vent are all arranged on the cross section of the air inlet exit and close to the tail part of the air plane body; the tail part exit of the air plane body measuring section is provided with a flow adjusting cone, and the flow adjusting cone is connected with a stepping motor by a drive screw. The experimental technology that air inlet characteristic and resistance measurement can be carried out on the same model of the invention solves the problem that the existing air plane can not acquire the actual resistance of air inlet when in designing process and can be applied to resistance characteristic comparison analysis of different air inlet schemes, thus the actual thrust resistance characteristic of air plane can be obtained.

Description

Inlet experimental device and working method that can be measured on the same model technical field The invention relates to an air inlet experiment technology capable of measuring performance and resistance on the same model, and belongs to the technical field of subsonic and supersonic air inlets and the technical field of aerodynamic experiments. Background technique The performance of the aircraft power plant has a great relationship with the working characteristics of the air inlet. The performance of the air inlet directly affects the thrust that the engine can produce and whether the engine can work normally. For a long time, researchers have been focusing on improving the aerodynamic performance of the inflow of the inlet and the flow field quality of the outlet of the inlet. There are few studies on the resistance characteristics of the inlet, and they are generally not measured in the performance research experiments of the inlet. Resistance, usually using theore...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M9/06G01M9/08

Inventor 李博梁德旺黄国平

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com