Manifold rock mass simulation test detection equipment

A technology for simulating testing and testing equipment, applied in the direction of using stable tension/pressure to test the strength of materials, etc., can solve the problems of test failure, poor accuracy, and inaccurate measurement, to improve the success rate, shorten the test time, The effect of improving stability

Inactive Publication Date: 2010-08-25

CHANGCHUNSHI HUAYU TESTING MACHINERIES INSTR

View PDF5 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Several series of products have been developed in China based on the "triaxial tester" for rock mass simulation test detection, but these products simulate the natural environment, the stress status of the sample in the deep crust and the creep properties of the rock (also The determination of "brittle-ductile critical strain rate" (called rock rheology) is not accurate enough

In addition, when using one host in the test, only one test can be done at a time (some tests need more than 180 days)

Since the deep underground is an invisible environment, detection tests and comparison tests must be carried out on rock samples at different depths or at different positions at the same depth. This is impossible for a host, and even if it is done, it will vary with time. Accidents lead to a large error between the test results and the actual data, and the test cycle is long, and the construction period will be seriously affected

In addition, the control system used by old equipment has slow data sampling speed and response speed, which often leads to test failure. The accuracy of the whole process curve and the critical strain rate test of brittle ductility is also very poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

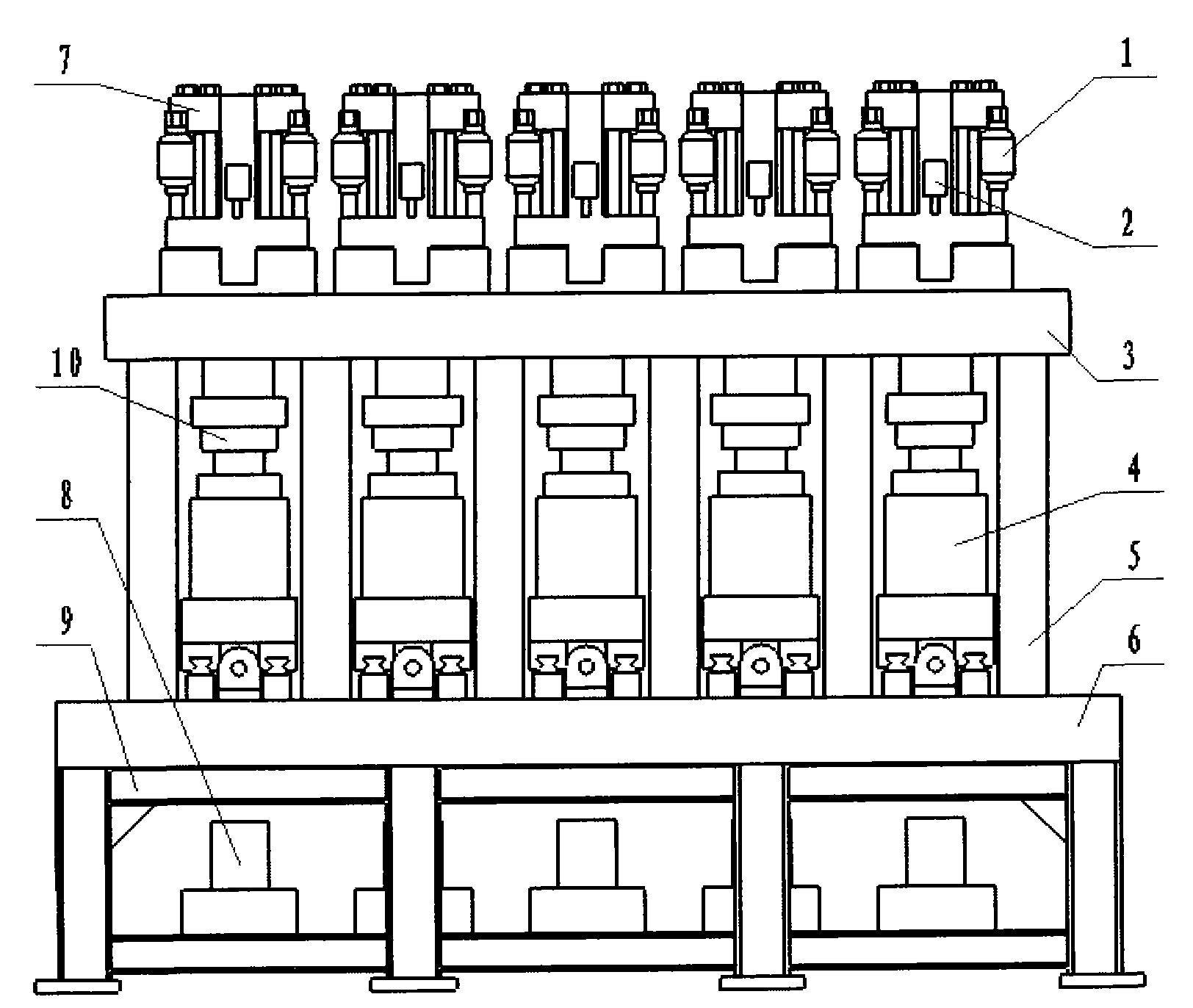

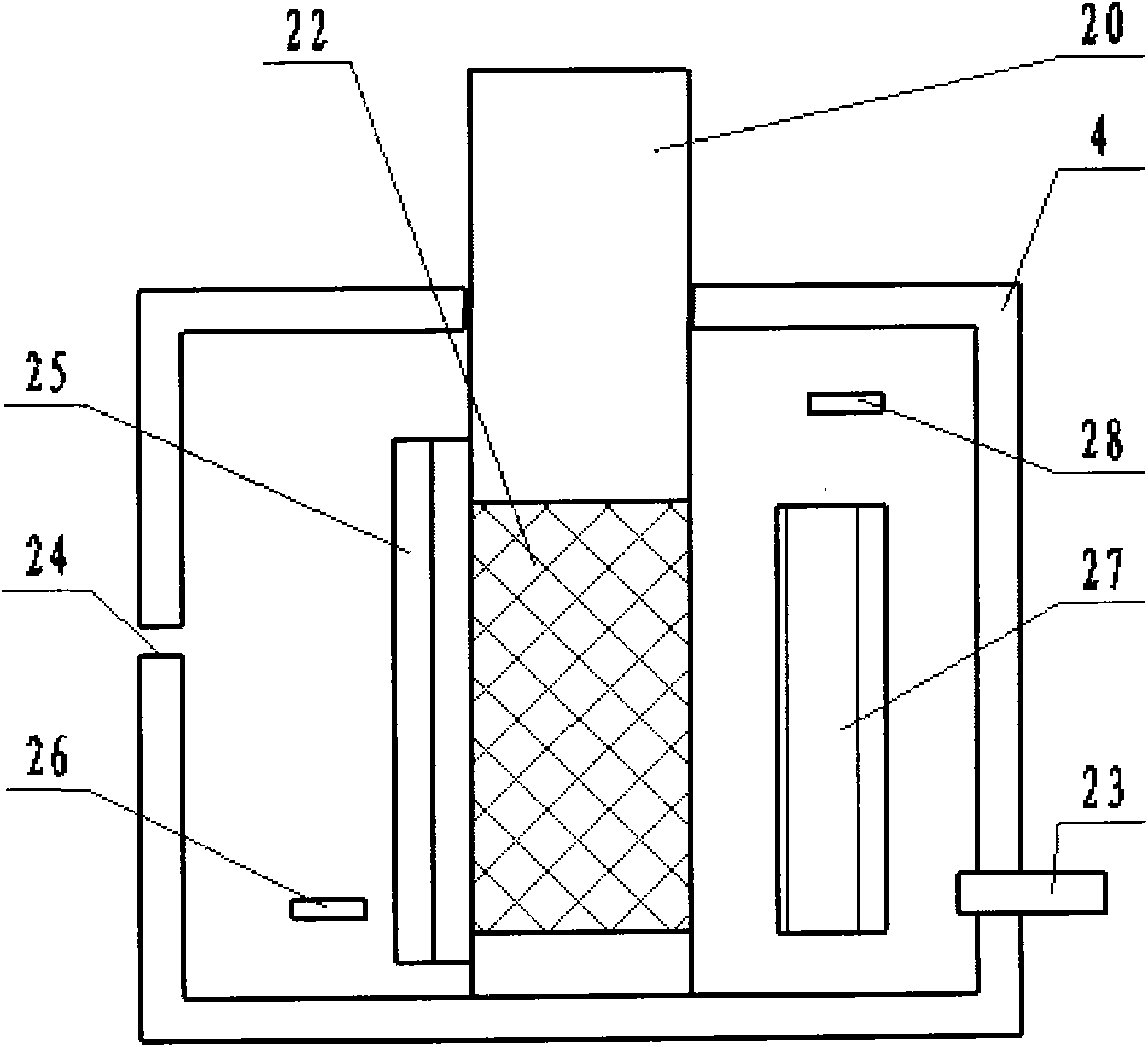

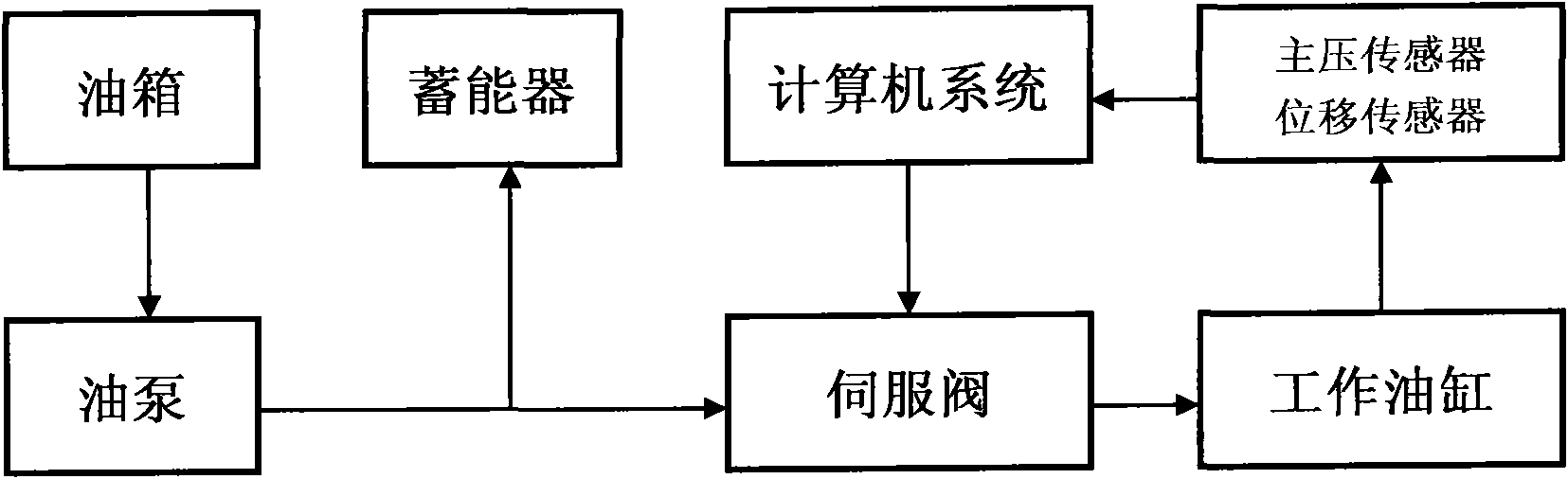

The invention relates to manifold rock mass simulation test detection equipment which is provided with more than 3 test groups, each test group comprises an axial loading system, a pressure chamber, a confining pressure loading system and a detection data recording system, and all test groups can carry out different simulation test detections. By adopting the structure, test time can be saved. All test groups are connected with a computer system and are controlled by the computer system, the computer system receives data output by the axial loading system and the pressure chamber and compares the data with preset simulation data, sends a regulation command to the axial loading system and the confining pressure loading system according to the comparison result to enable main pressure and confining pressure of the pressure chamber to be kept stable, and automatically records a detection result. The data sampling speed and the response speed of the computer system are high, therefore, the success rate and the accuracy of the test are high.

Description

Multiple rock mass simulation test testing equipment technical field The invention relates to a device for testing and detecting changes in physical properties of rock mass by simulating environment. Background technique The natural stress state of the crustal rock mass is closely related to human engineering activities. It is not only an important factor determining regional stability, but also often has a direct impact on the design and construction of various buildings. Practice has shown that the excavation of rock mass during the construction of surface and underground projects in high-stress areas can often cause a series of deformation and failure phenomena in the interior of the rock mass associated with unloading springback and stress release. The result is Not only will it deteriorate the engineering geological conditions of the foundation or slope rock mass, but the action itself will sometimes cause direct damage to buildings. It is an important task of engin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/12

Inventor 李岩

Owner CHANGCHUNSHI HUAYU TESTING MACHINERIES INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com