Pressure head device for loading normal triaxial rheology and testing acoustic emission under high confining pressure

A triaxial rheological and acoustic emission technology, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve problems such as unsatisfactory test results, failure, oil leakage, etc., and achieve ideal test results , to avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

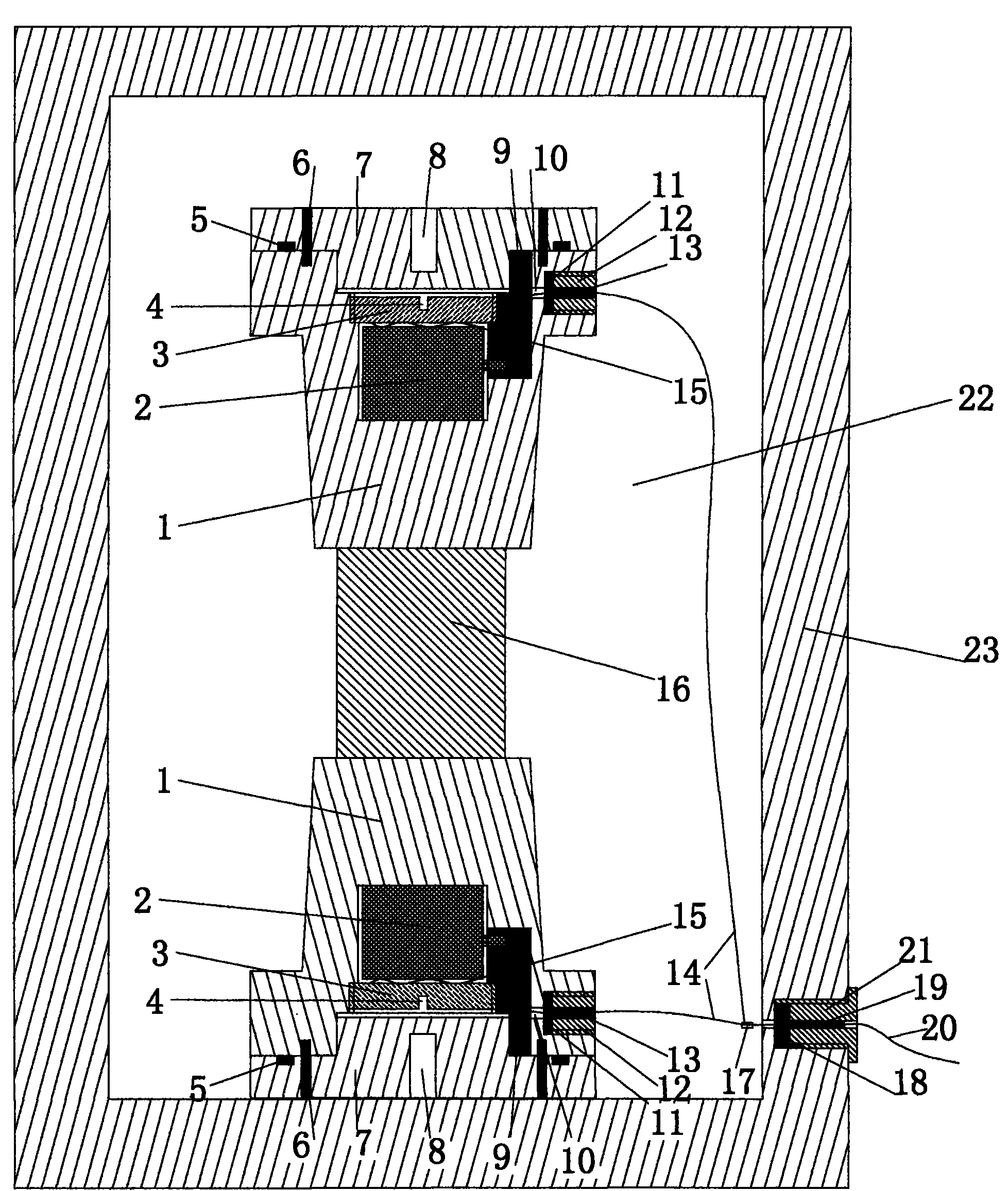

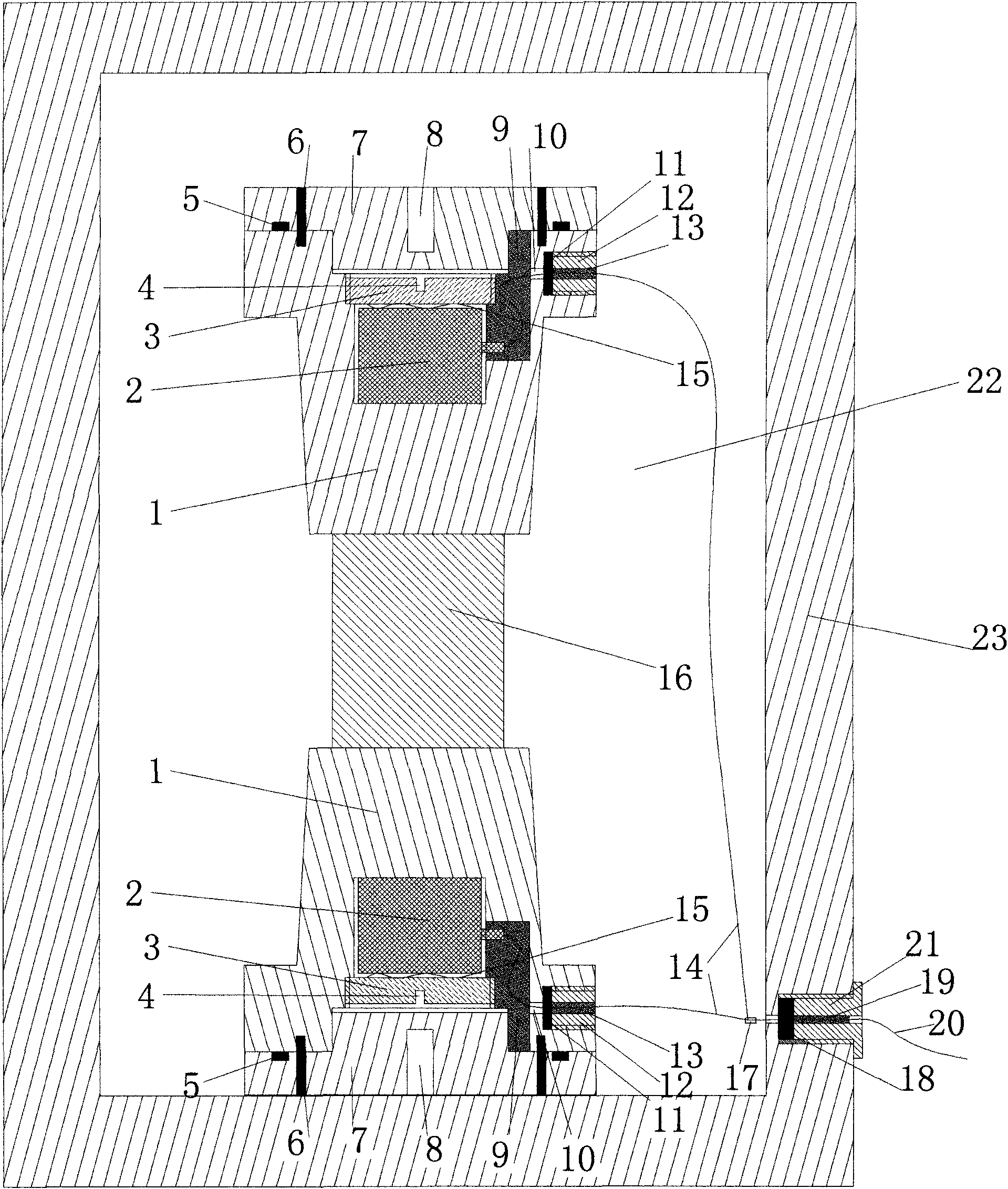

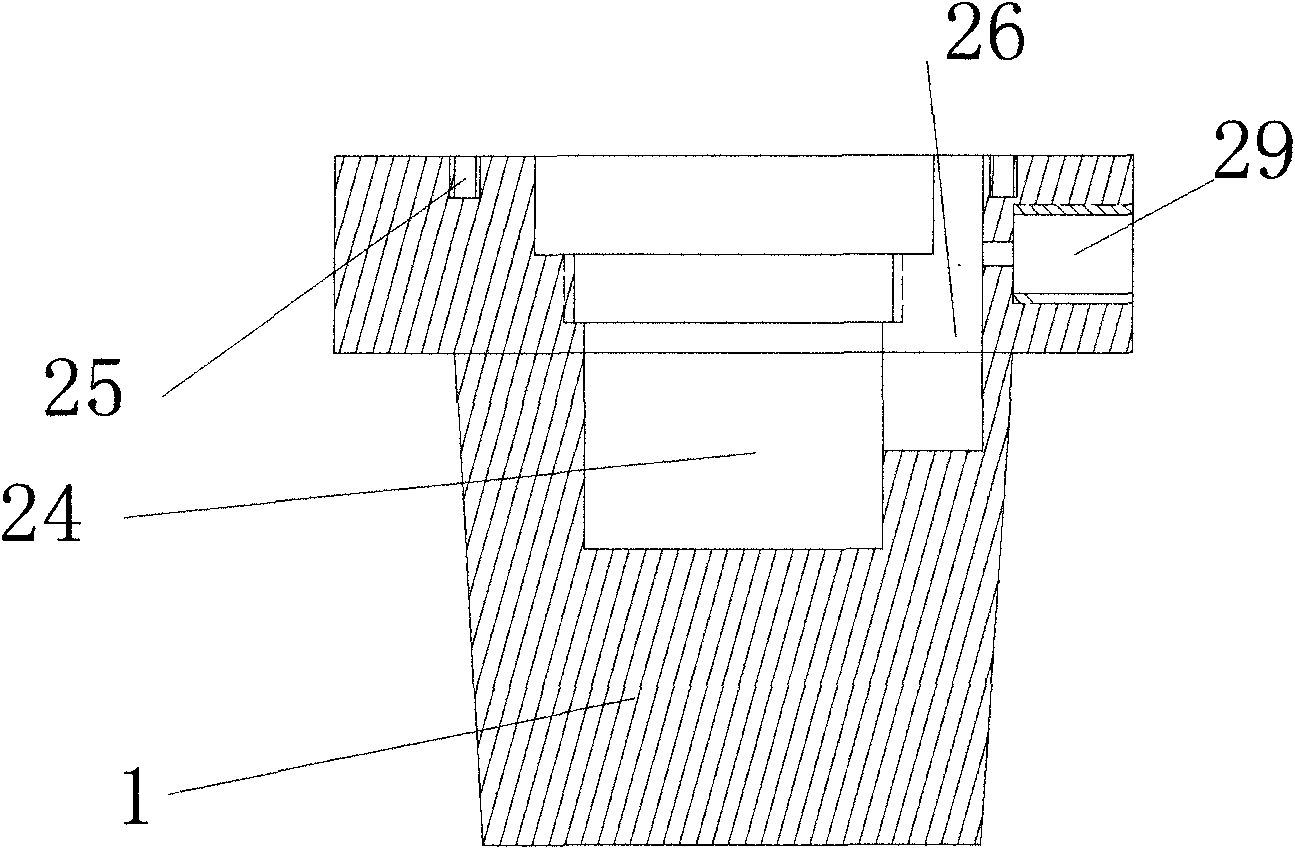

[0028] A high confining pressure conventional triaxial rheological loading and acoustic emission test indenter device, which includes an indenter base 1, an R6a sensor 2, a fastening bolt 3, a groove for the fastening bolt 4, a main sealing ring 5, a main Sealing cover bolt 6, main sealing cover 7, centering guide groove 8, E44 type epoxy resin 9, outlet hole 10, side sealing ring 11, side sealing cover 12, YZJ-1 bonded steel structure adhesive 13, BNC coaxial Cable 14, flexible gasket 15, rock sample 16, coaxial cable convex-concave joint 17, warehouse body sealing ring 18, YZJ-2 bonded steel structure glue 19, syv-50-3 coaxial cable 20, warehouse Body sealing cover 21, pressure chamber 22, pressure chamber body 23, sensor chamber 24, main sealing cover nut 25, outlet groove 26, main sealing groove 27, side sealing cover groove 28, side sealing cavity 29, side sealing cover outlet Hole 30, bin body sealing cover groove 31.

[0029]Taking the rheological acoustic emission tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com