Portable density testing device with high precision and testing method

A testing device and high-precision technology, applied in the direction of material analysis by measuring buoyancy, can solve problems such as poor measurement accuracy, and achieve the effects of easy disassembly and portability, simple structure, and high measurement accuracy

Inactive Publication Date: 2010-08-25

WANTONG ZHONGBAO ALUMINUM WHEEL ZHEJIANG +1

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved and the technical task proposed by the present invention are to overcome the defects of poor measurement accuracy of existing density testing instruments and provide a high-precision portable density testing device and method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

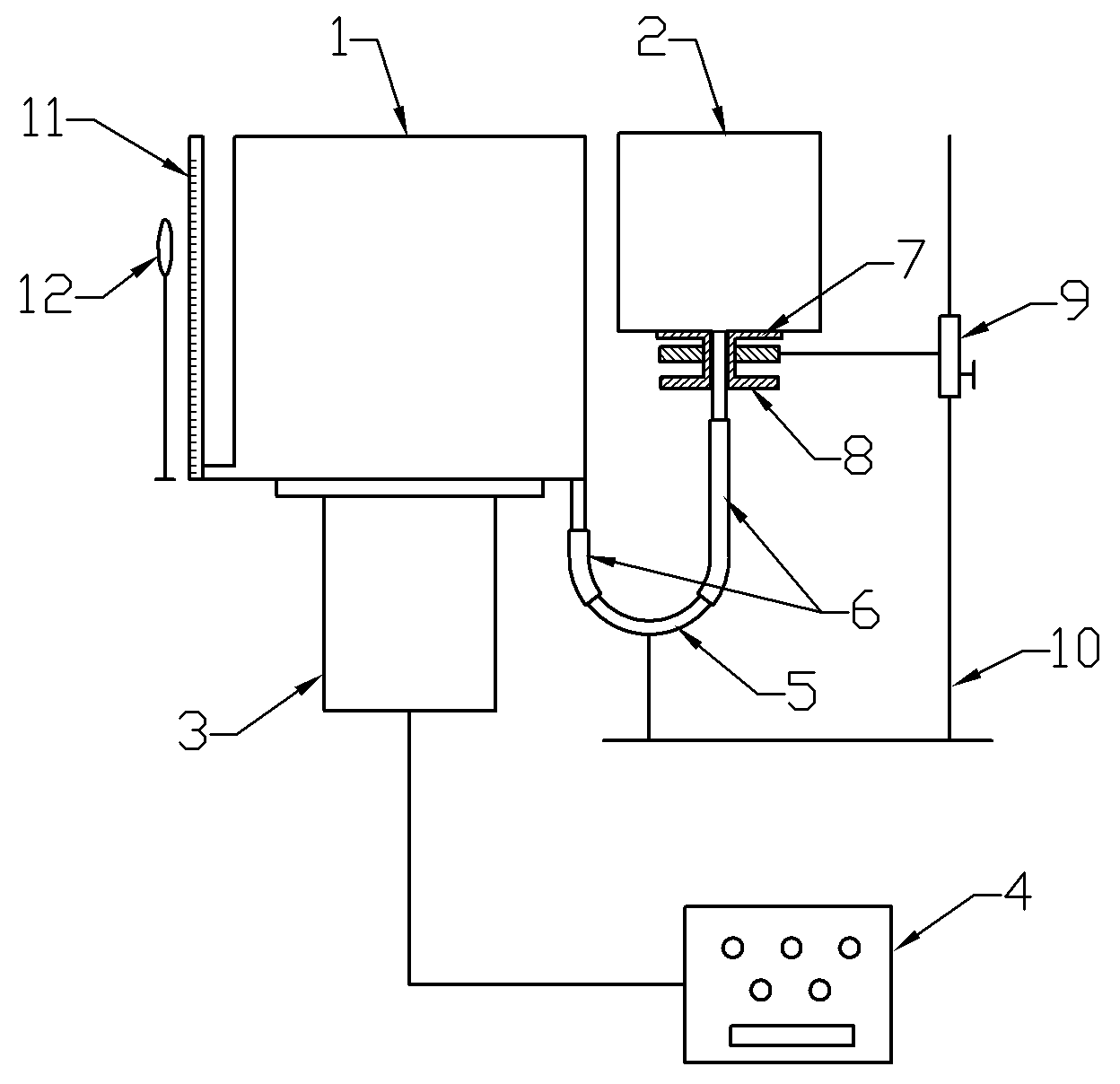

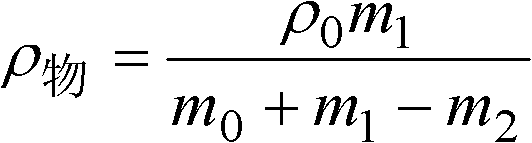

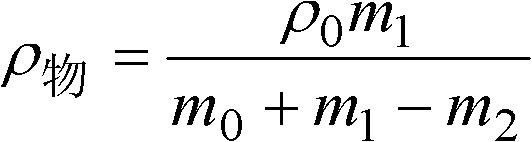

The invention discloses a portable density testing device with the high precision, belonging to the field of instruments and meters. A conventional density testing instrument has poor testing precision. The portable density testing device with the high precision comprises a measuring container and an auxiliary container with adjustable height, wherein the auxiliary container is communicated with the measuring container; the measuring container is placed on a weighing sensor connected with a digital display operating device; the digital display operating device comprises a data processing module, an input module, a registering module and a display module, and the input module, the registering module and the display module are connected with the data processing module. The portable density testing device with the high precision has the advantages of simple and convenient operation, easy implementation of digital display, high measuring speed and high measuring accuracy without manually calculating the density testing. The testing device is simple to construct, and easy to detach and carry with low manufacturing cost. The instrument can be applied to fields of chemical industry, mineral separation, substance evaluation and the like, and can be widely applied to precious stone evaluation, low-grade noble metal ore detection, die casting pore detection and the like requiring extremely high precision.

Description

High-precision portable density testing device and method technical field The invention belongs to instruments and meters, and is mainly used in chemical industry and mineral processing, especially in the identification of precious stones, the detection of low-grade precious metal ores, the measurement of pores in die-casting parts, etc., which require extremely high precision. Background technique In the fields of chemical industry, mineral processing, and material identification, density is the most basic constant of matter, and it is the data often used in production and scientific research. The measurement of material density is one of the main means of material quality control. Through density measurement, the fluctuation of material composition and process conditions such as temperature can be controlled. For example, in the process of oil drilling, abnormal formation pore pressure is extremely dangerous for oil wells, which may cause accidents such as well kick, blo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N9/08

Inventor 闫焉服

Owner WANTONG ZHONGBAO ALUMINUM WHEEL ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com