Method for identifying plate defect and damage based on nonlinear acoustics and time reversal principle

A nonlinear acoustic and time-reversal technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, to achieve the effects of improving signal-to-noise ratio, accurate identification and evaluation, and avoiding complexity

Inactive Publication Date: 2010-08-25

HARBIN UNIV OF SCI & TECH

View PDF0 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the nonlinearity of the flaws in the plate breaks the symmetry of the time-reversal rule, then the energy will not focus where desired

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for identifying plate defect and damage based on a nonlinear acoustics and time reversal principle. In the traditional method, the detection on small cracks in a plate is difficult to satisfy people, and therefore, the accuracy and the sensitivity of the traditional method are lowered. The method comprises the steps of: 1, transmitting transducer pumping signals: arranging a defined quantity of transducer arrays on a plate to be measured, and generating two pulse signals by a random waveform signal generator to be used as pumping signals; 2, selection of time reversal window signals: receiving transmission signals of the step 1 in a medium by a receiving transducer, carrying out nonlinear spectrum analysis on the received signals, and carrying out time reversal on the selected time window signals with nonlinear characteristic parameters; 3, obtained focus signals: loading the signals subjected to the time reversal in the step 2 to the transmitting transducer arrays again, and receiving the focus signals at the receiving part; and 4, defect or damage identification evaluation: analyzing the focus signals in the step 3, and finding out the relation between the defect or damage and the nonlinear characteristic parameters. The invention is applied to detection and identification of a plate structural member.

Description

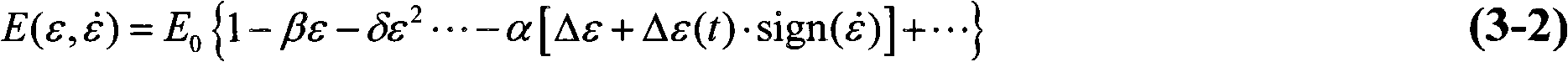

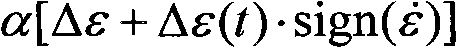

Technical field: The invention relates to the field of non-destructive testing, in particular to a plate defect and damage identification method based on nonlinear acoustic modulation spectrum technology and time reversal principle. Background technique: Sheet metal structures are widely used in aerospace, automobile industry and civil engineering, and play an indispensable role. Since the sheet will produce defects or damage during the forming and use process, when these defects or damage are located in the middle of the plate thickness, it is difficult to detect with the naked eye. resulting in fatigue damage. Therefore, it is very necessary to detect and identify the plate-shaped structural parts. Ultrasonic nondestructive testing is one of the widely used methods. However, the existing ultrasonic methods mainly use linear acoustic parameters such as sound velocity, impedance, and sound pressure to realize crack identification. Although the analysis process is simpli...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N29/12

Inventor 李大勇高桂丽董静薇石德全王利华

Owner HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com