Liquid crystal display device and manufacturing method thereof

A liquid crystal display and device technology, applied in the field of liquid crystal displays, can solve problems that affect the brightness and contrast of the display screen, reduce the clarity of the display screen, and reduce the light transmittance of the liquid crystal panel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

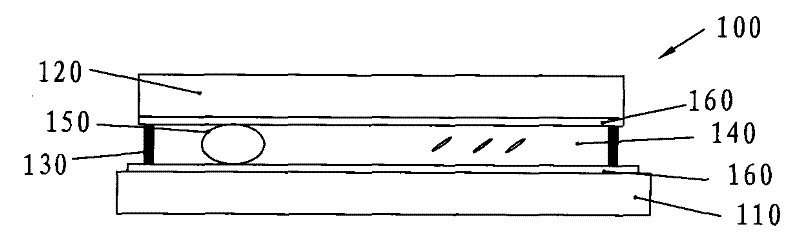

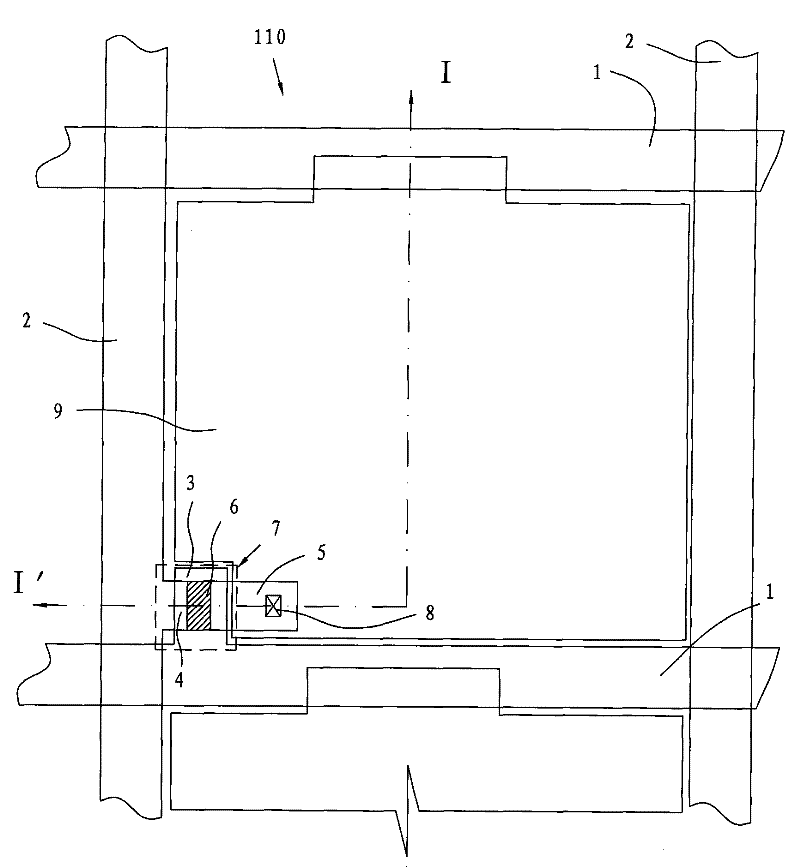

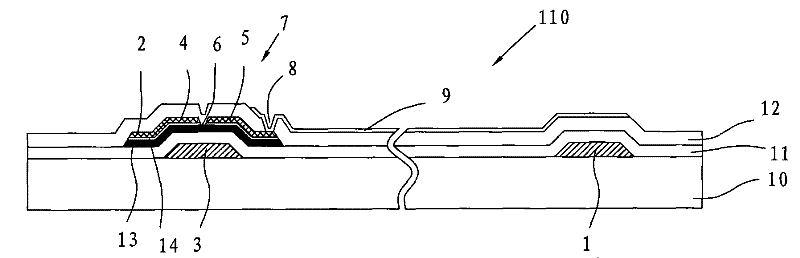

[0038] An embodiment of the present invention provides a liquid crystal display device, such as Figure 4 and Figure 5 As shown, the thin film transistor array substrate of the liquid crystal display device includes gate scan lines 420 and data scan lines 410 intersecting each other on the substrate 456, The thin film transistor 450 is switched, and a pixel electrode 440 is also included in the area defined by the intersection of the gate scan line 420 and the data scan line 410 . The cross-sectional structure of the switching thin film transistor 450 is as follows Figure 5 As shown, the switching thin film transistor 450 includes a gate 451 connected to the gate scanning line 420, a source 452 connected to the data scanning line 410, a drain 453 connected to the pixel electrode 440, and a gate electrode 453 overlapping with the gate scanning line 420 and The semiconductor layer 459 a defines the channel 454 between the source electrode 452 and the drain electrode 453 . A...

Embodiment 2

[0050] An embodiment of the present invention provides a method for manufacturing a liquid crystal display device. In the process of manufacturing a TFT array substrate, a photosensitive thin film transistor and a signal line parallel to a data scanning line are formed while manufacturing a switching thin film transistor; The source and gate of the light-sensitive thin film transistor are connected to one of the gate scanning lines that define the pixel unit, and the drain is output to the signal line; then an auxiliary barrier with a reflective layer on the surface is prepared on the color filter glass substrate A spacer, the auxiliary spacer is correspondingly disposed directly above the channel of the light-sensing thin film transistor, and there is a space reserved between the light-sensing thin film transistor and the light-sensing thin film transistor.

[0051] In order to convert the photocurrent generated by the photosensitive thin film transistor into a more obvious si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com