Step-down constant current LED drive circuit for automobile lighting

A technology for LED driving and automotive lighting, which is applied in the field of electric lighting, and can solve problems that affect the service life of high-power LEDs, short circuits, open circuits, and LED driver module failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

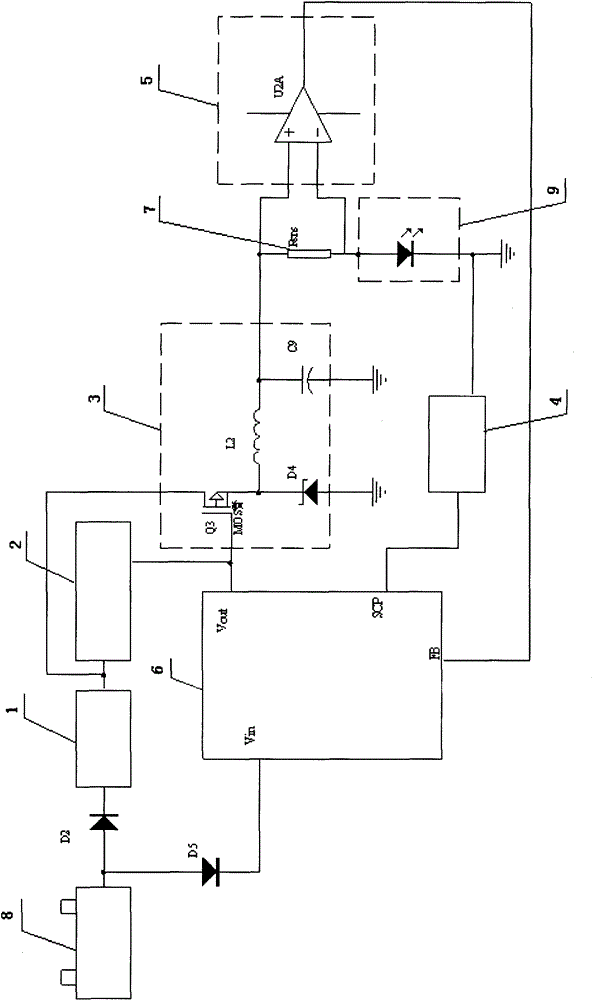

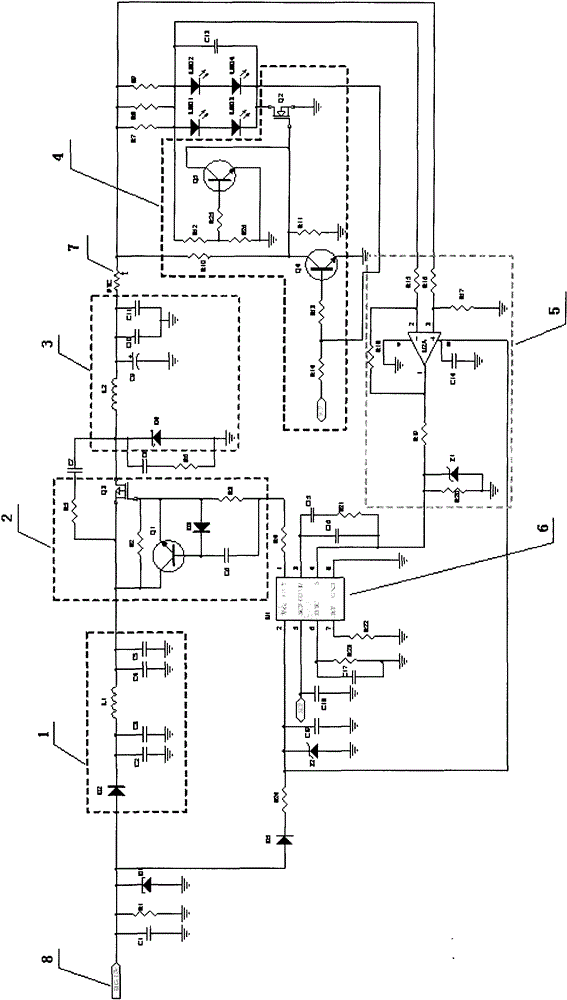

[0022] as attached figure 1 As shown, a step-down constant current LED drive circuit for automotive lighting includes: isolation circuit module 1, MOS tube drive circuit module 2, conversion circuit module 3, PWM control chip 6 (the chip model adopted is Texas Instruments TI The company's TL5001 series chip), feedback circuit module 5 and protection circuit module 4; the DC power supply 12V for automobiles supplies power to the isolation circuit module 1 through the anti-reverse diode D2, and the signal filtered by the isolation circuit module 1 is output to the MOS tube drive The circuit provides the MOS transistor Q3 with a gate-source voltage difference sufficient to turn it on and off, and at the same time, the PWM control chip 6 outputs a square wave pulse signal to the MOS transistor Q3 to control the opening and closing of the MOS transistor Q3, and the on-off duty ratio of the MOS transistor Q3 goes to To control the energy of the conversion circuit, the conversion cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com