Jet rod spraying machine and jet rod replacing method thereof

A sprayer and spray boom technology, applied in spraying devices, liquid spraying devices, etc., can solve the problems of affecting the quality of trellis-type plants, reducing the speed of sprayers, and low efficiency of trellis-type plants, so as to improve the deposition of droplets effect, reduce drift, improve the effect of spray application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

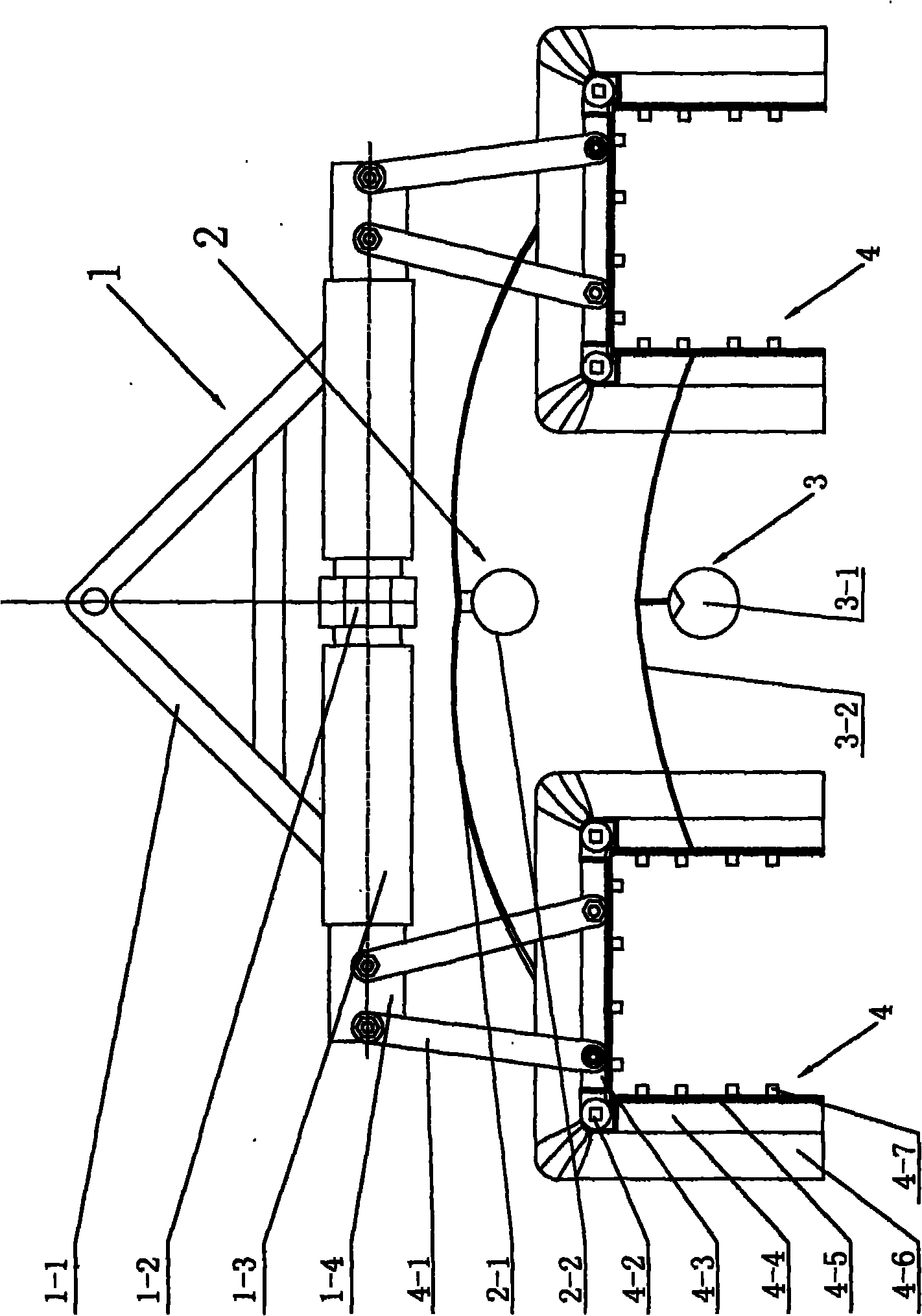

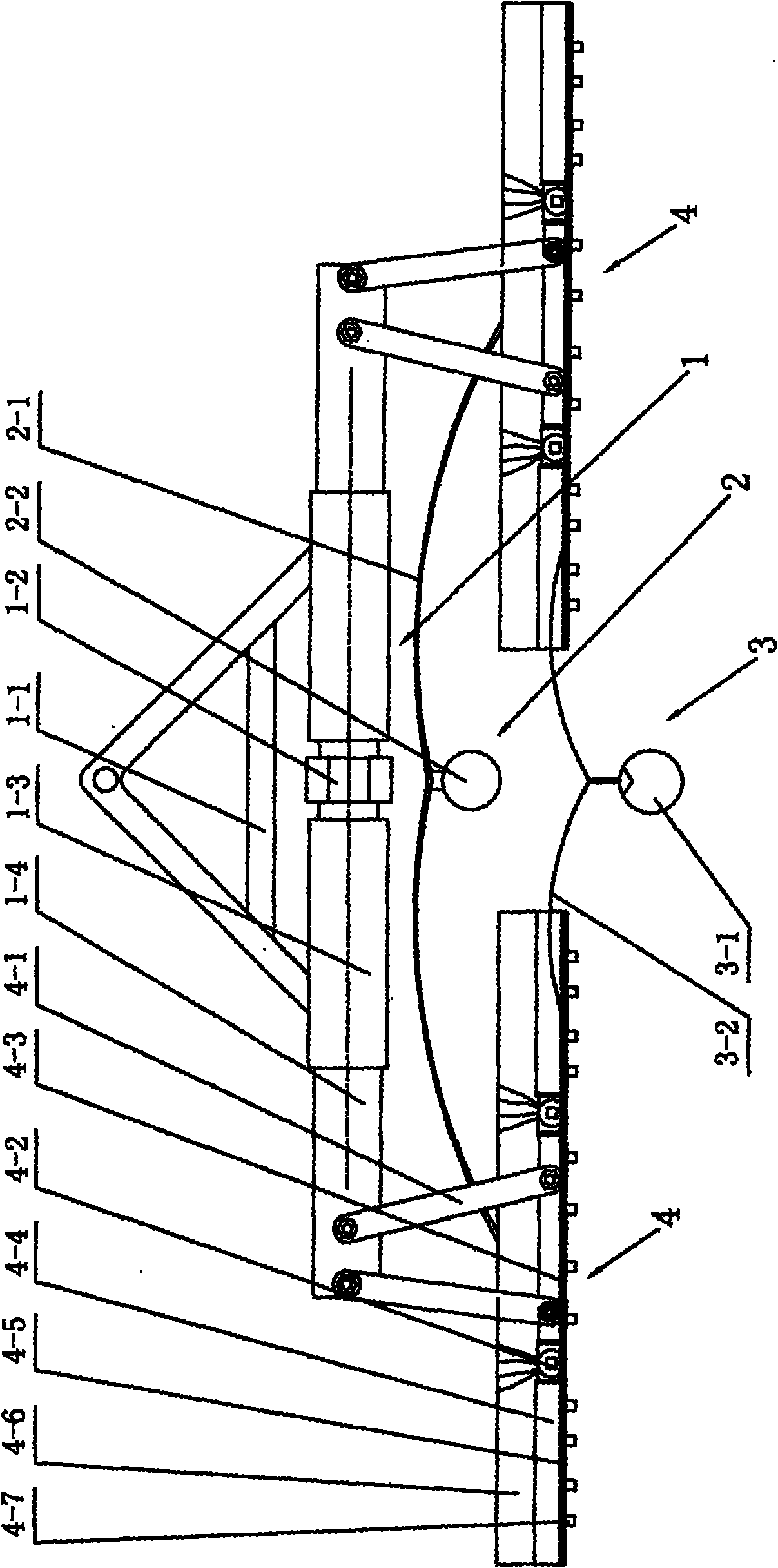

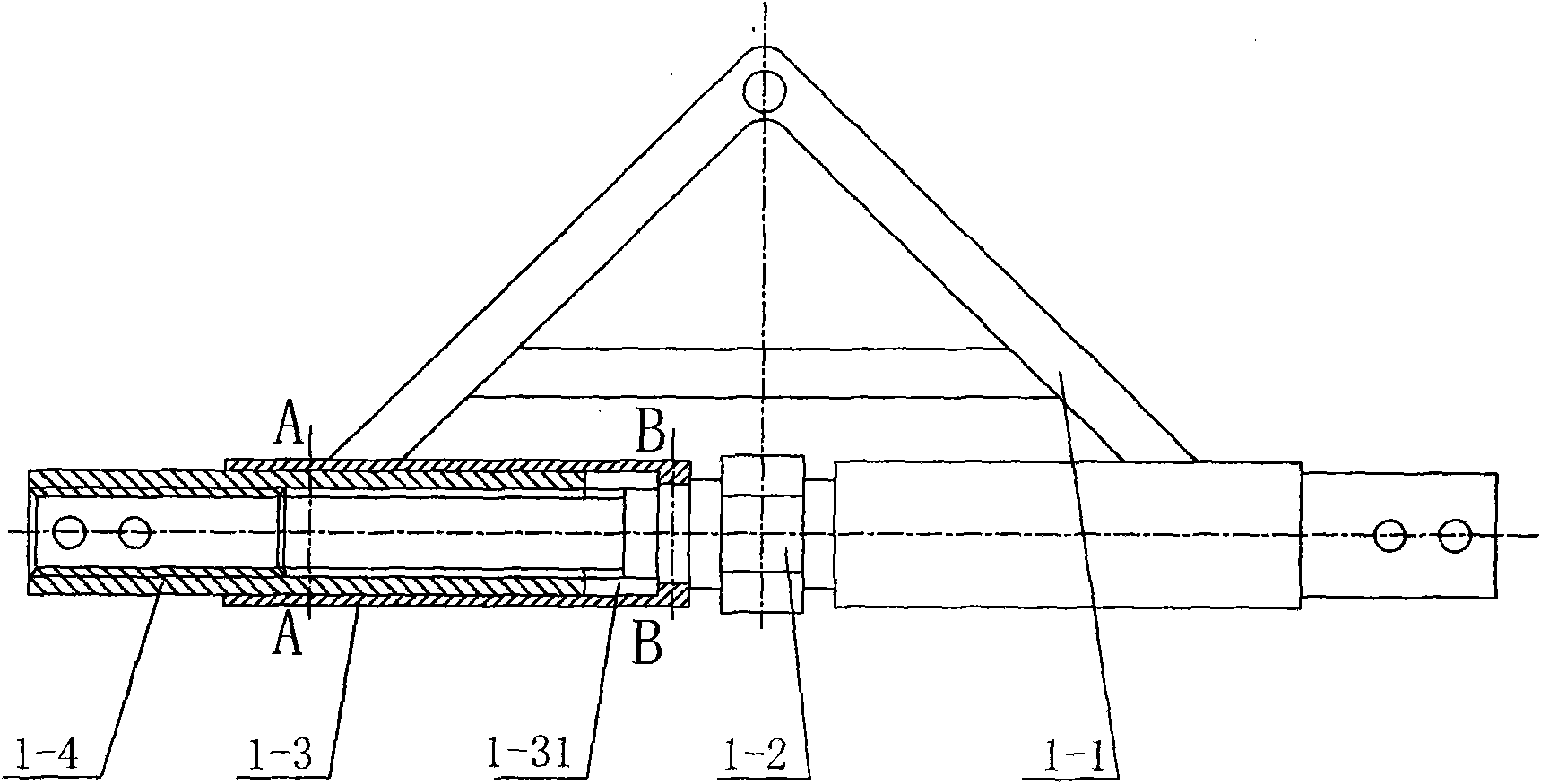

[0026] See figure 1 , 2 As shown, the boom sprayer of the present invention includes a suspension assembly 1, more than two boom air curtain assemblies 4, a liquid medicine delivery assembly 3 and an air supply assembly 2. See Figure 3-5 As shown, the suspension assembly 1 of the present invention includes a suspension frame 1-1, two telescopic rods 1-4 and an adjustment rod 1-2, the suspension frame 1-1 has two fixed mounts 1-3, and the suspension frame 1-1 1 Adopt a conventional triangular structure, or a suspension frame structure matched with different types of tractors or automobiles. There are threaded holes in the two telescopic rods 1-4, and the threaded holes of the two telescopic rods 1-4 rotate in opposite directions. That is, the two telescopic rods 1-4 have left-handed threaded holes and right-handed threaded holes respectively. For the convenience of positioning, the two telescopic rods 1-4 adopt a polygonal structure, such as Figure 4 Shown in the figure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com