Valve arrangement structure for cylinder head of air-cooled diesel engine

A technology of layout structure and cylinder head, which is applied in the direction of cylinder, cylinder head, air cooling, etc., can solve the problems of increased valve movement difference, cooling dead angle, and influence of cylinder head cooling effect, etc., so as to achieve the effect of motion balance and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

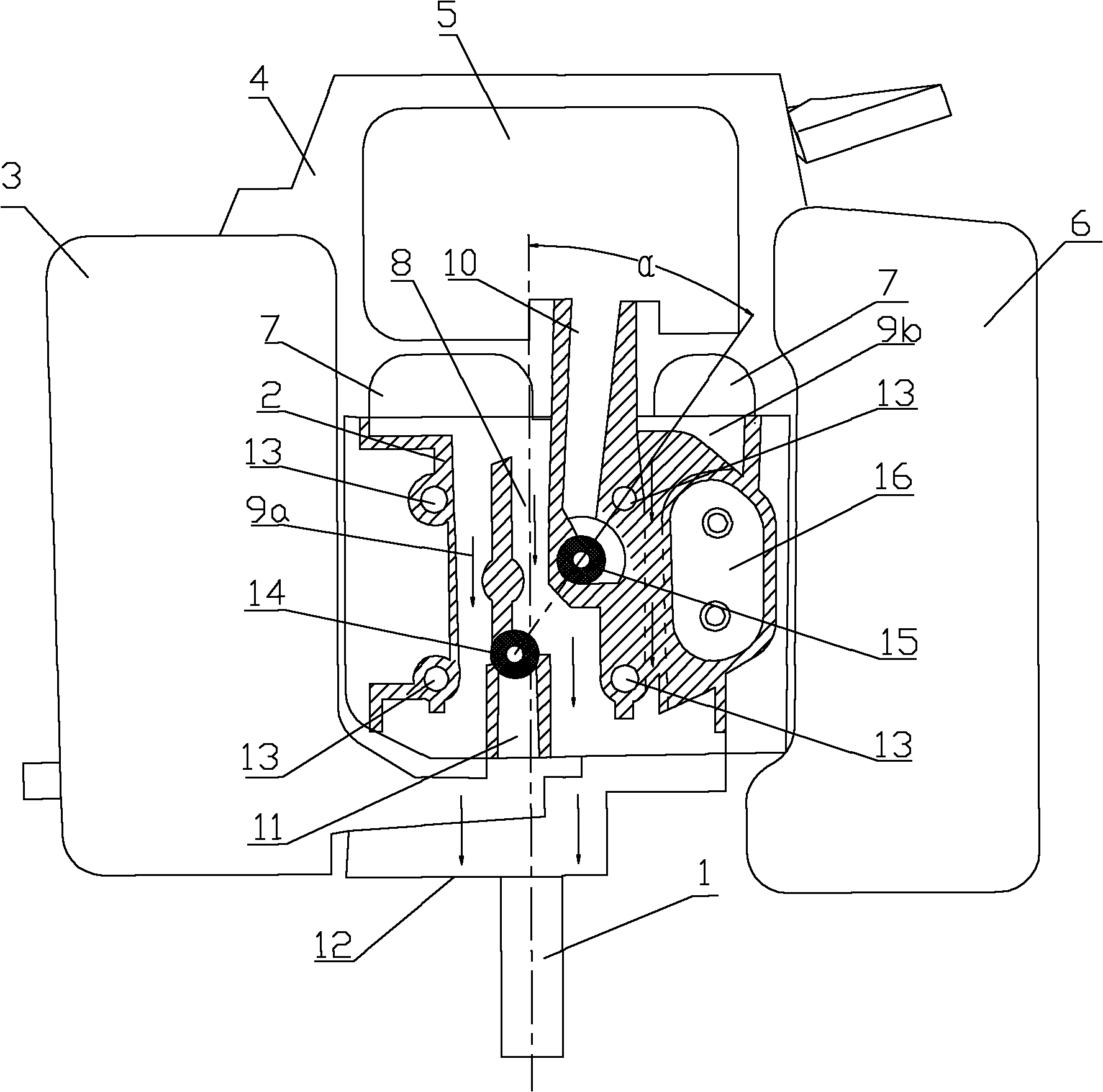

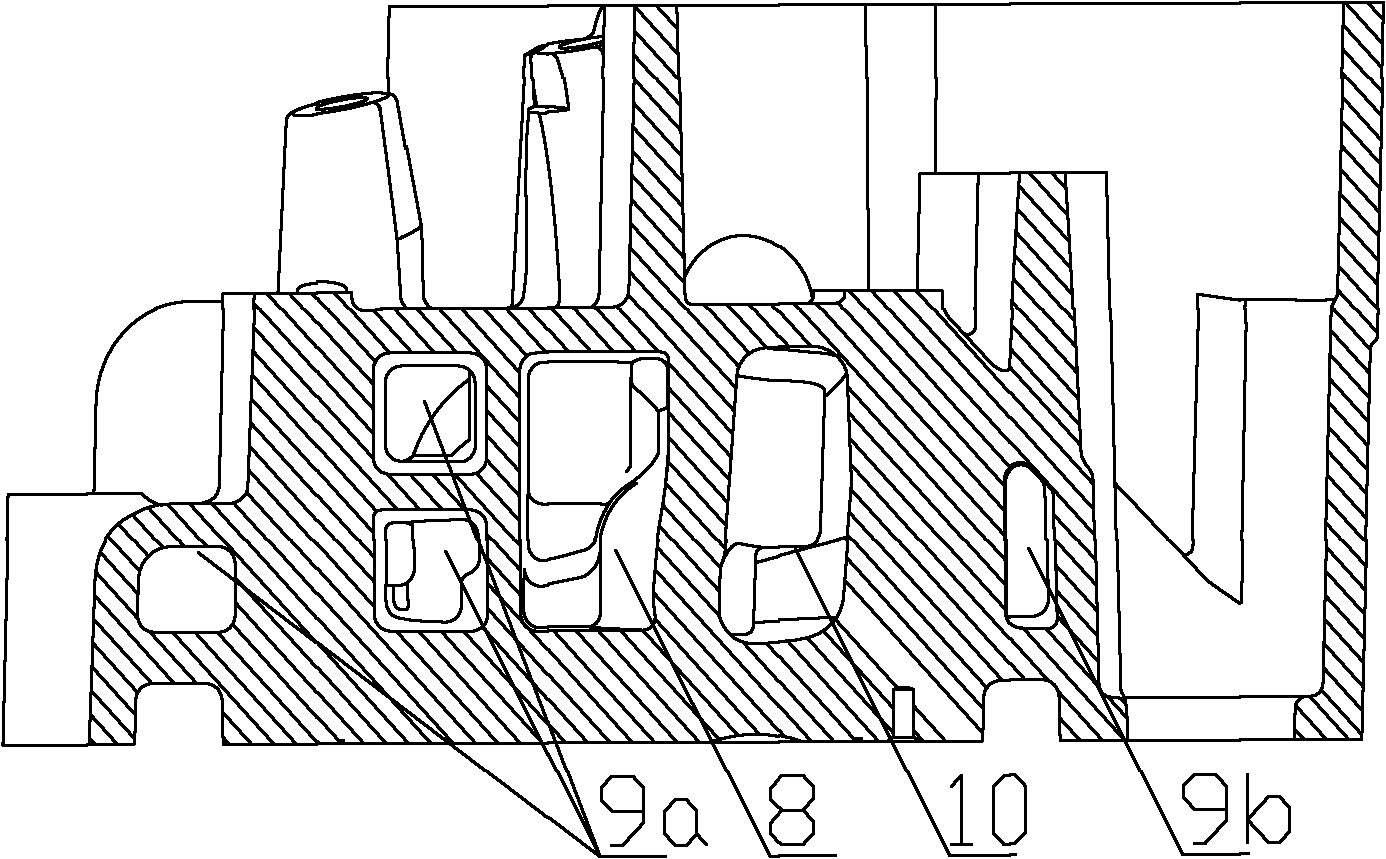

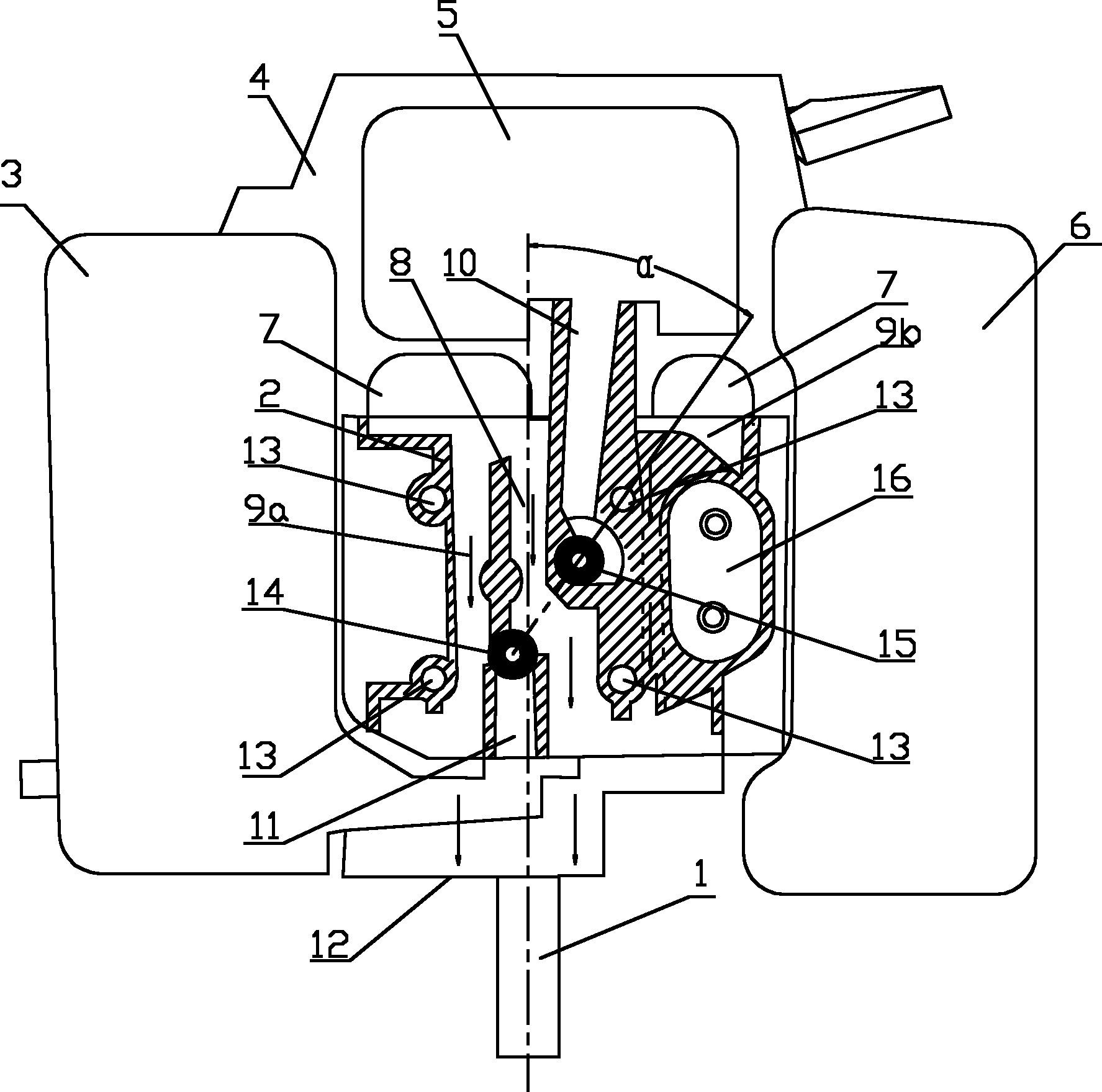

[0014] refer to figure 1 and figure 2 , air-cooled diesel engine cylinder head valve arrangement structure, diesel engine includes crankcase and cylinder head, cylinder head is installed above the crankcase, cylinder head 2 solid part is provided with a number of mounting holes, through the mounting holes through the connecting bolt 13 to put the cylinder head Connect and install with the crankcase. A crankshaft 1 is arranged in the crankcase, and the crankshaft 1 protrudes from the side of the crankcase. The muffler 3 is installed on the left side of the crankcase, the oil tank 6 is installed on the right side, and the starter 4 and the air filter 5 are installed on the upper side. 5 is located above the starter 4, and an air guide cover 7 is installed between the air filter 5 and the cylinder head 2, and the air guide cover 7 guides the cooling wind formed by the rotation of the wind wheel to the side of the cylinder head. Diesel engine cylinder head 2 has intake passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com