Tensile testing equipment of trampoline tension spring

A technology of tensile test and trampoline, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. It can solve problems such as unsatisfactory detection results, and achieve easy observation and replacement, high test efficiency, and easy operation. Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

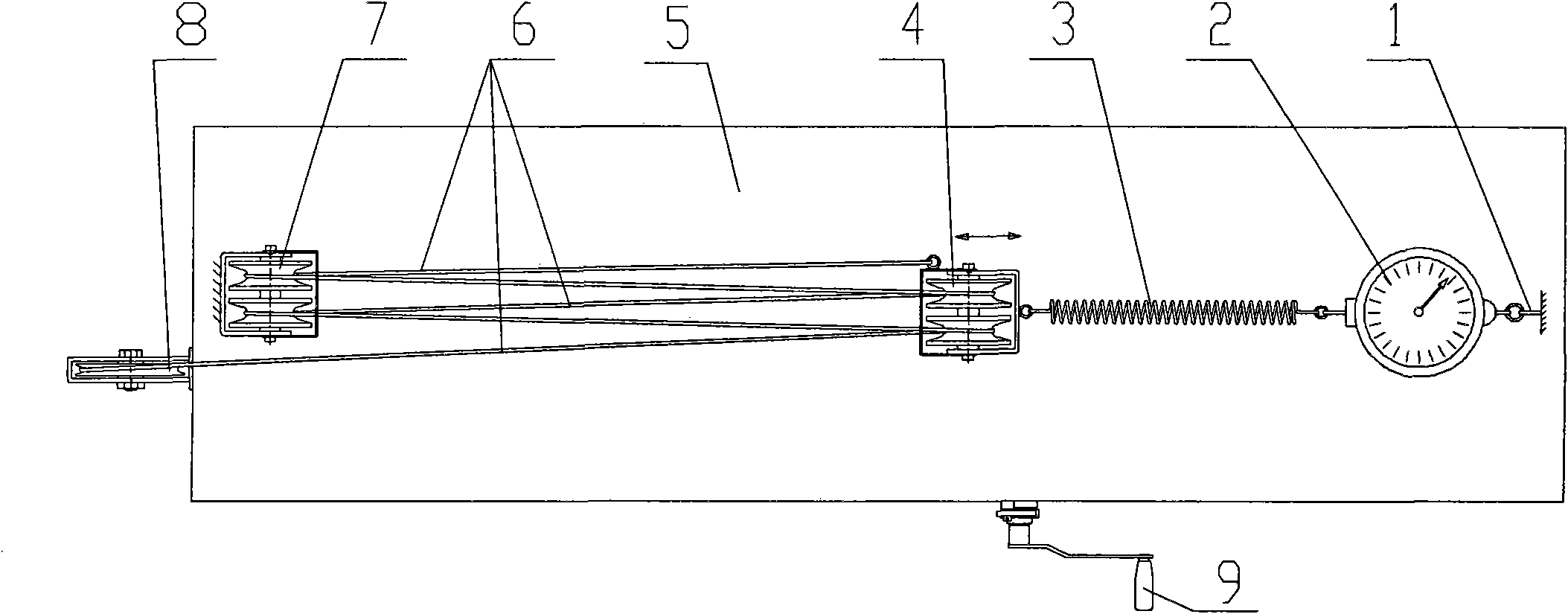

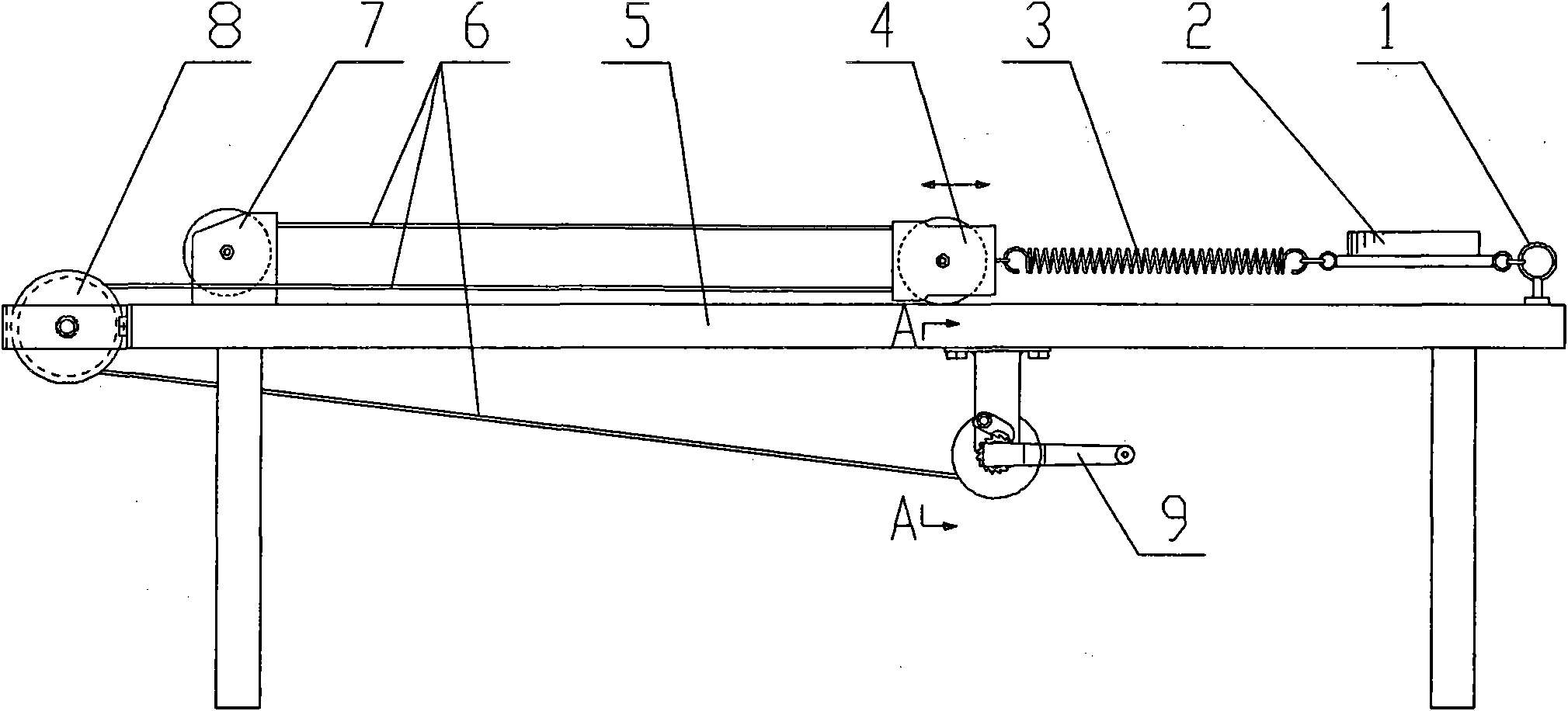

[0016] Figure 1-3 Among them, the two ends of the upper part of the frame 5 are respectively provided with a fixed ring 1 and a fixed pulley block 7, one end side of the frame 5 is provided with a reversing pulley 8, and the lower part of the frame 5 is provided with a rope winding device, and the fixed ring 1 is fixed with a Tension indicator 2, the stay rope 6 on the fixed pulley block 7 walks around the reversing pulley 8 on the movable pulley block 4 on the frame 5 and the frame 5 one end side successively and is connected with the stay cord winding device of the frame 5 bottoms.

[0017] The fixed pulley block 7 and the movable pulley block 4 are all made up of two coaxial pulleys connected in parallel.

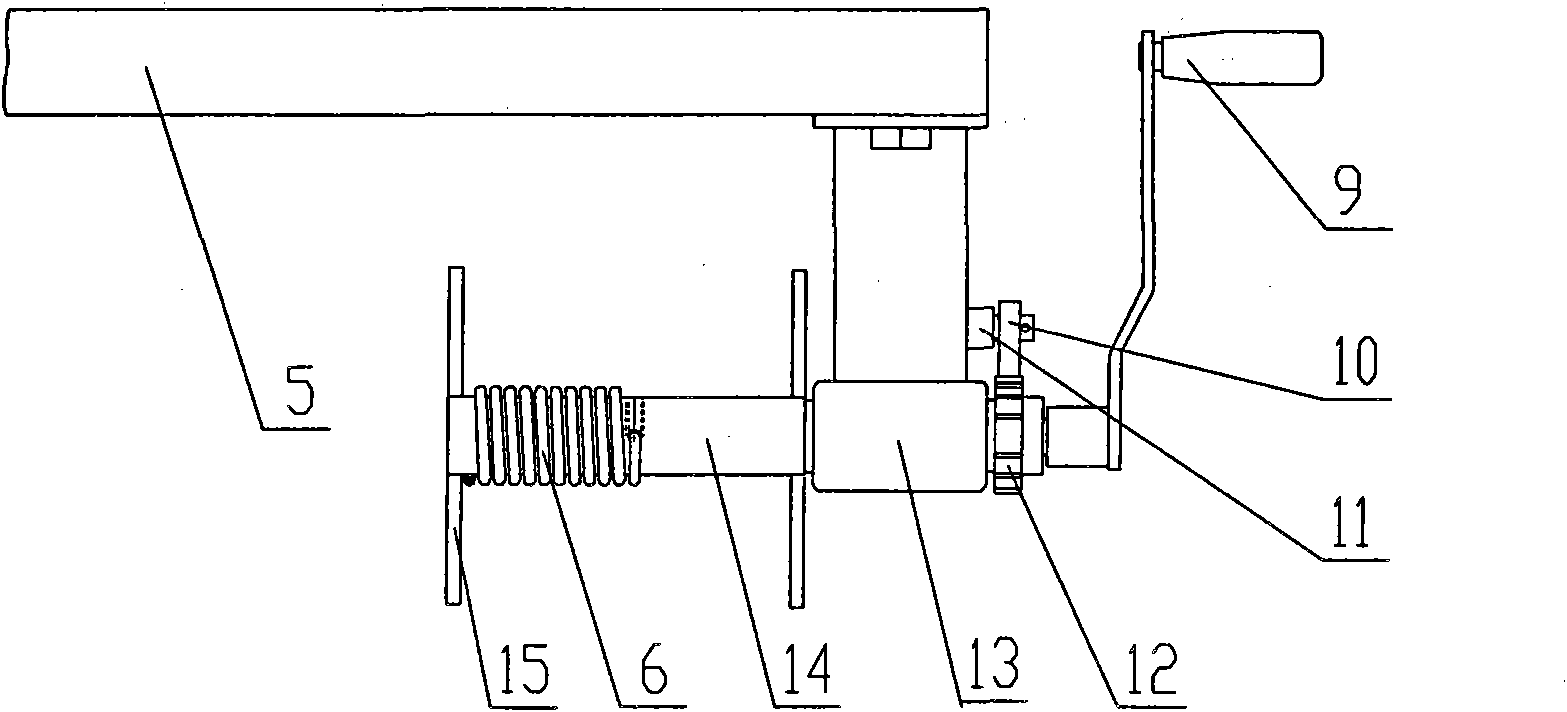

[0018] The stay cord winding device includes a stay cord shaft sleeve 13 fixed on the bottom of the frame 5, a stay cord shaft 14 is worn in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com