Low-frequency inner-coupled electrodeless fluorescent lamp

An electrodeless fluorescent lamp and in-coupling technology, applied in the direction of discharge lamps, parts of gas discharge lamps, electrical components, etc., can solve the problems of high cost, high excitation coil temperature, and low lamp efficiency, so as to prolong the service life and reduce work Frequency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

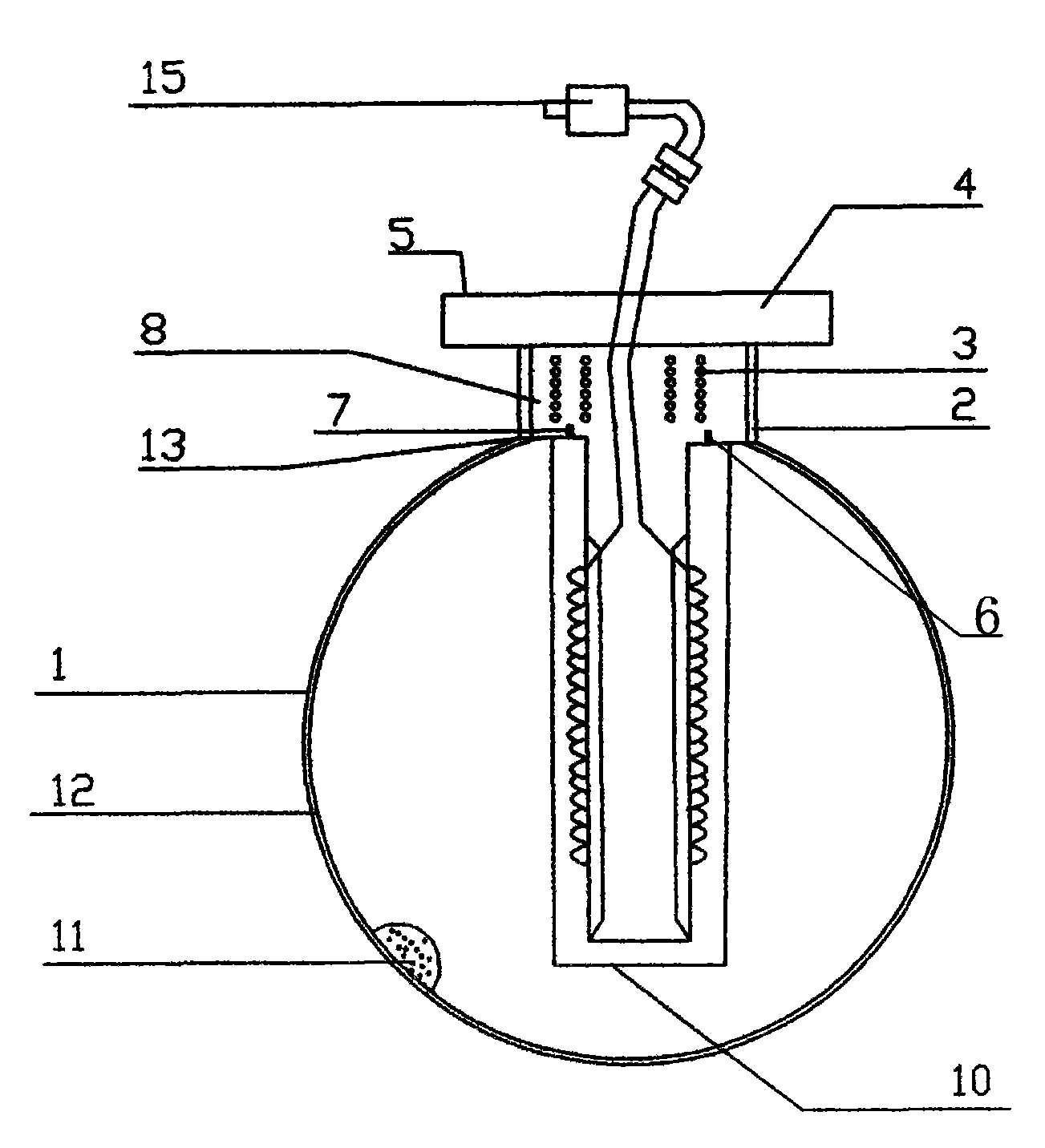

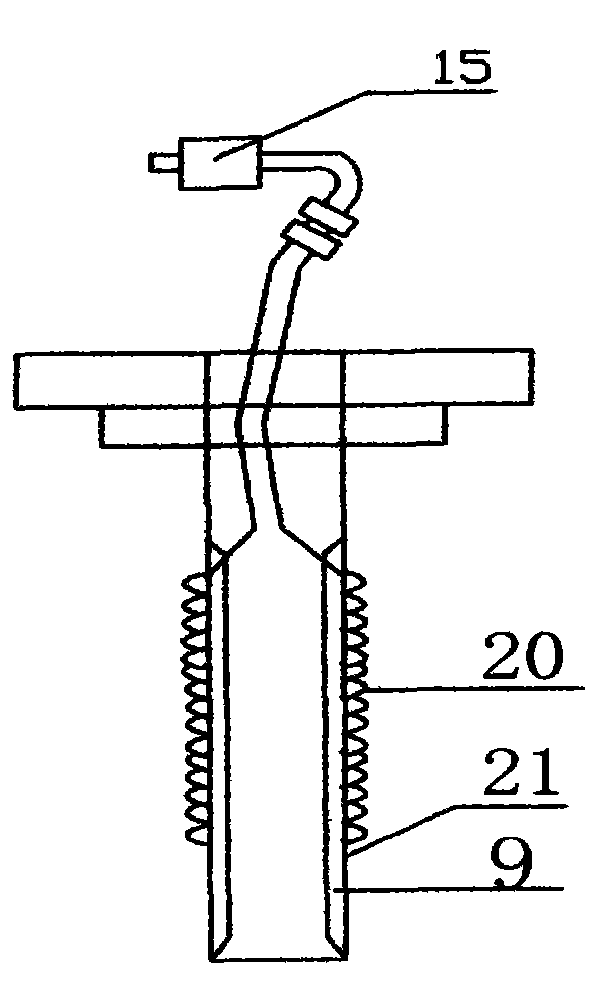

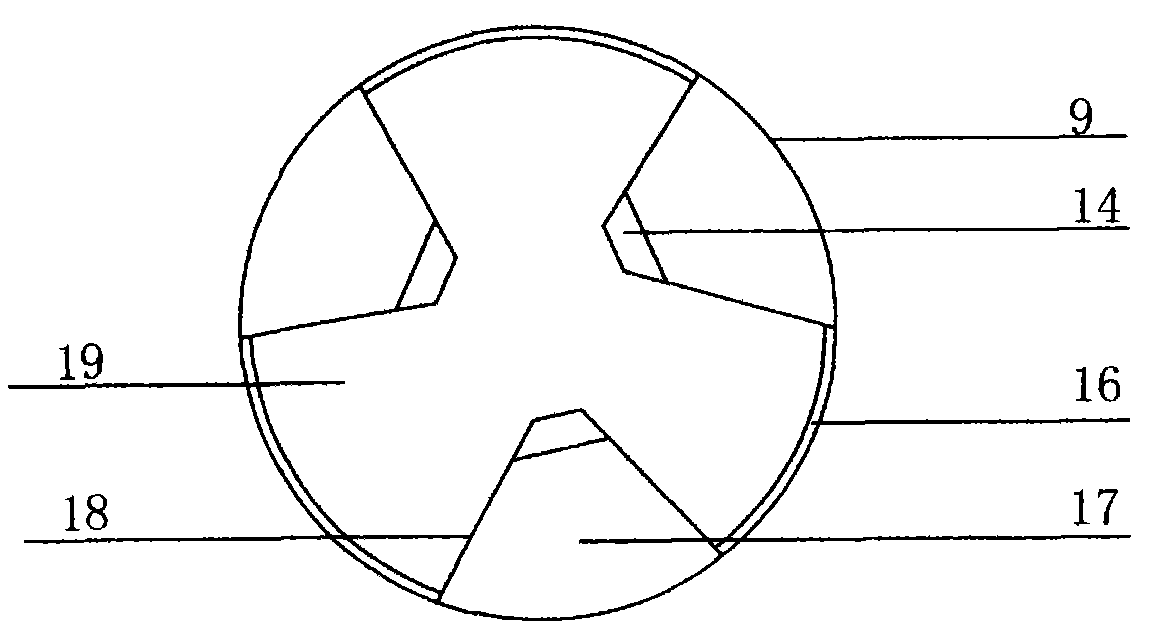

[0018] Refer to attached figure 1 , low-frequency internal coupling electrodeless fluorescent lamp, its main structure is composed of glass bulb 1, internal power coupler, lamp holder 8, heat conduction base 4, low-frequency ballast 15, etc.; There are heat dissipation holes 3 on the base 8, the lamp base 2 is screwed and fixedly connected with the lamp base 8, the lamp base 8 is fixed on the heat conduction base 4, there are 2 to 5 installation holes 5 on the periphery of the heat conduction base 4, and a glass stem 10 The sealing connection 13 is fixedly installed inside the glass bulb 1, and the small glass tube welded at both ends of the upper part of the glass stem 10 is respectively equipped with an indium mesh 7 and an amalgam 6, and an inner coupling is arranged inside the glass stem 10. The inner wall of the glass bulb 1 is coated with fluoresc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com