Transverse shifting mechanism of rape cutter-rower

A technology of a toggle mechanism and a windrower, which is applied to harvesters, agricultural machinery and implements, and other applications, and can solve problems such as the blockage of the discharge outlet and the inability to ensure that the rapeseed can be separated from the conveyor smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

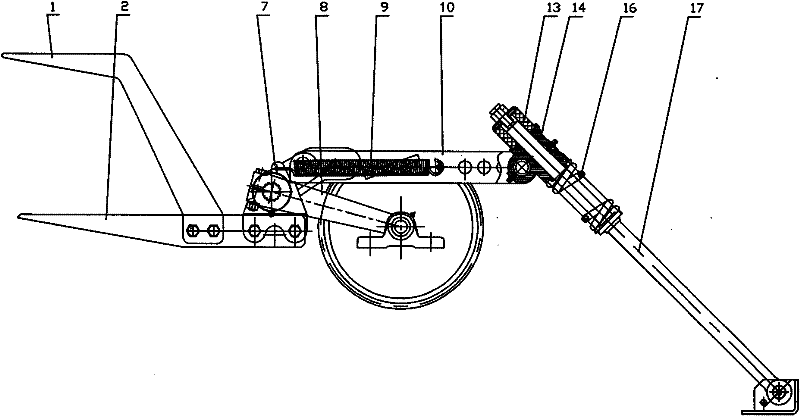

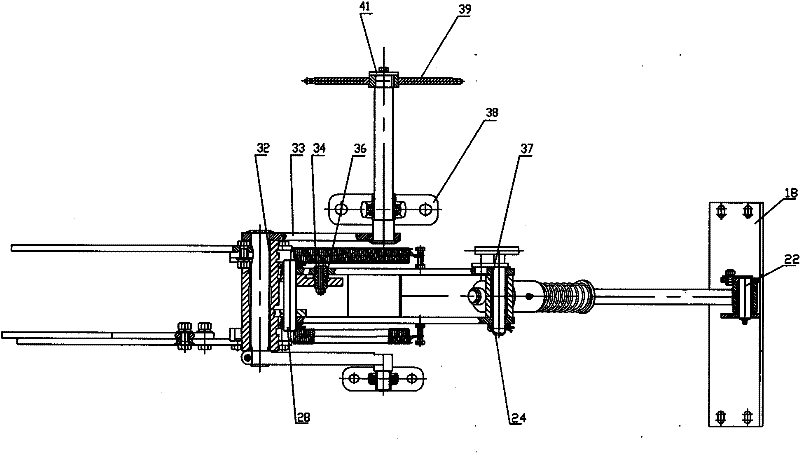

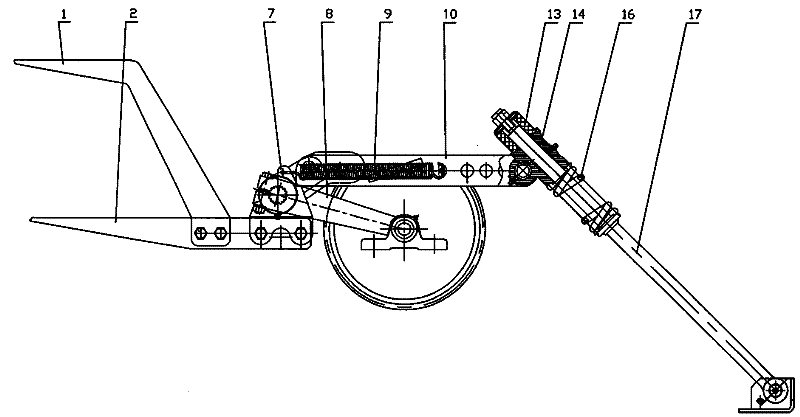

[0013] The transverse toggle mechanism of the windrower for rape in this embodiment is as follows: figure 1 with figure 2 Shown, its essence is crank rocker mechanism, basically constitutes: the two ends of crank 33 are respectively welded with spacer shaft 32 and an end supported on the sprocket shaft on belt seat bearing 38, and are Z-shaped. The other end of the locator shaft 32 is fixedly connected to the collet at one end of the connecting handle 8, and the other end of the connecting handle 8 is hinged on another bearing coaxial with the sprocket shaft, thereby forming a double-branch with simple structure, convenient assembly and stable movement. Side crank construction. The other end of the sprocket shaft is constrainedly connected with the sprocket 39 as the windrower rotation drive mechanism through the baffle plate 41 . The crank 33 is hinged with the center hole of the locator 7 through the locator shaft 32 welded therewith, and the two upper interval holes of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com