Automatic feeding device of thin type sheet iron piece

A technology of automatic feeding and small parts, which is applied in the direction of unstacking, transportation and packaging of objects, and can solve the problems of high labor intensity, missing pieces, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

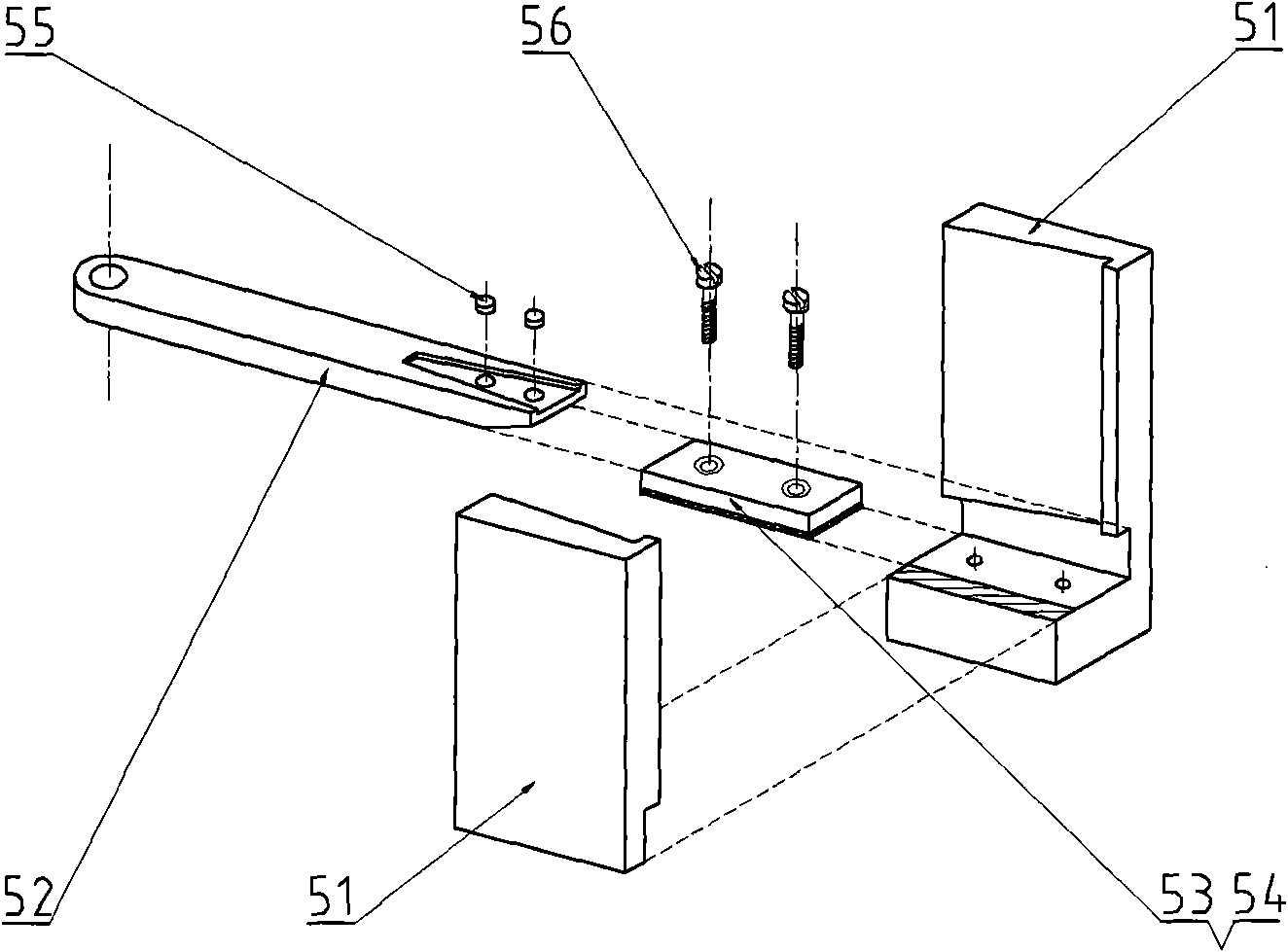

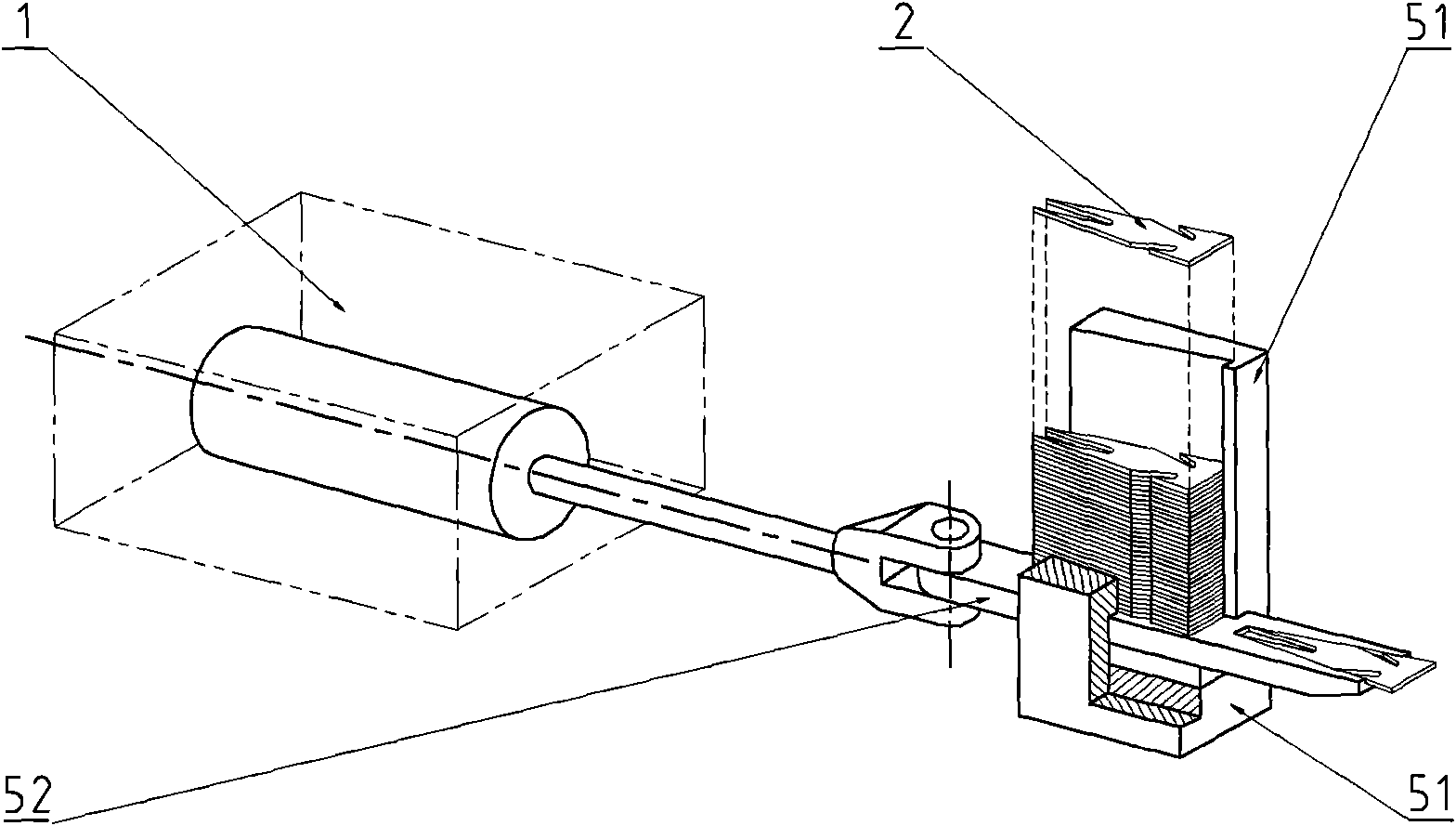

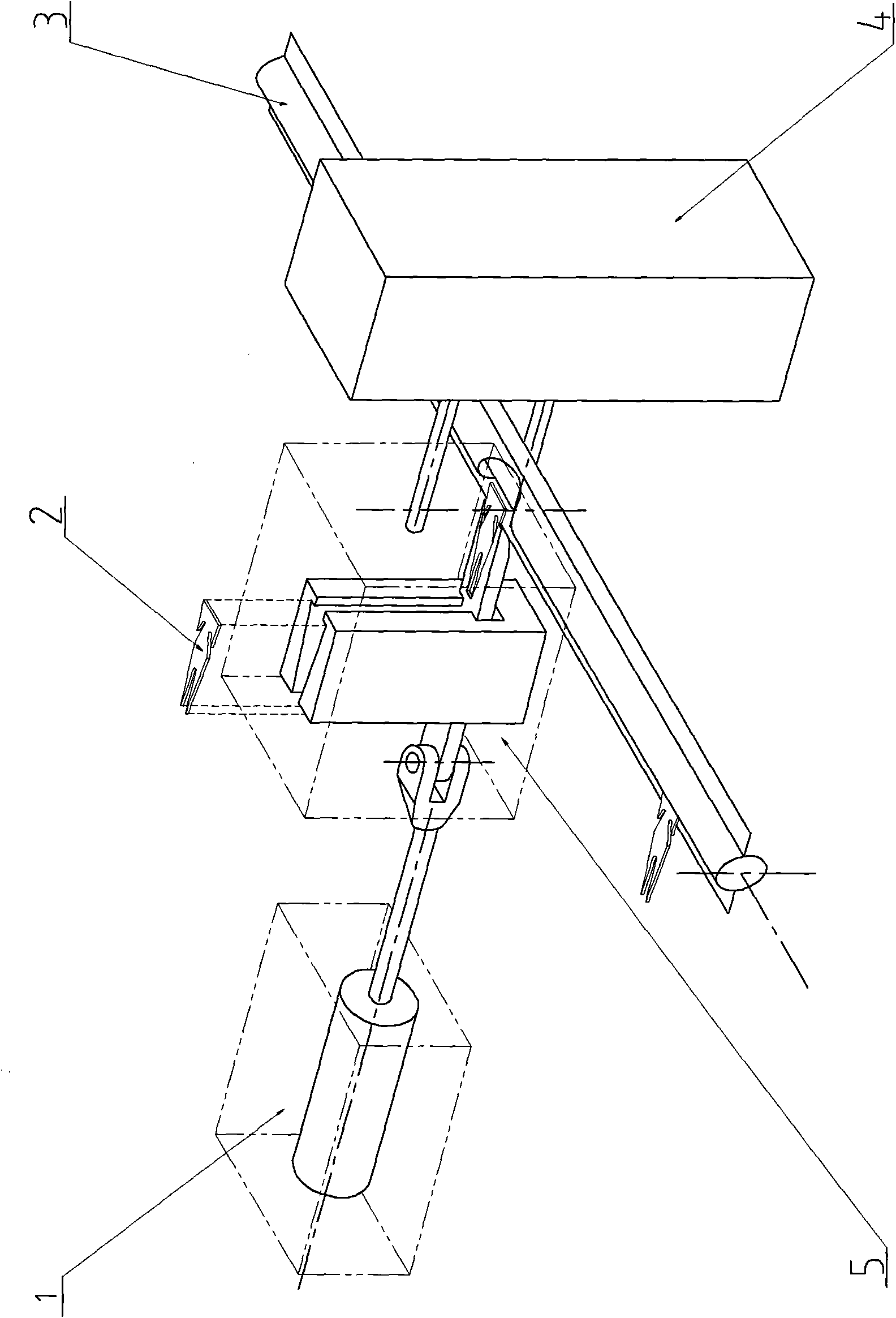

[0009] Below in conjunction with accompanying drawing, the present invention is further described: the present invention is feeding device [5], is made of material storehouse [51], feeding tongue [52], adjustment pad [53], liner [54], magnet [55], screw [56] composed of. In order to clearly reflect its structure, function and role, it is now described in conjunction with the transmission mechanism [1], mans teeth [2], tube blank [3], and spot welding machine [4] in this embodiment. The embodiment It is mainly to solve the problem of automatically conveying the awn teeth [2] to the welding point during the production of the R-S line of the electrostatic precipitator in the automatic production line. The transmission mechanism [1] can be pneumatic, hydraulic or other mechanical transmission (in this case, cylinder transmission is adopted); the material storehouse [51] is designed according to the planar shape of the awn tooth [2], and the function is to limit the position and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com