Method for adjusting and treating municipal residual sludge by using salinferous brine or seawater

A technology for excess sludge and salt brine, applied in the field of environmental engineering, can solve the problems of reduction, high disposal cost, high price, etc., and achieve the effects of simple process, saving chemical raw materials, and convenient and feasible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

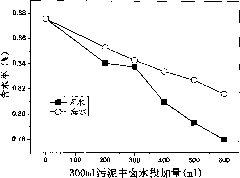

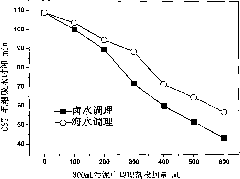

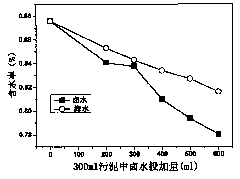

[0017] Embodiment 1: Take the residual sludge of the municipal sewage plant as the test object, its initial water content is 99.5%, after it is left to settle for a period of time, the supernatant is removed, and now the water content is 98%. Take 500ml of the sludge and place it in a 2000ml beaker, then add 1000ml of brine or seawater, stir for 15 minutes; let it settle for 15 minutes, then remove the supernatant; then put the remaining sludge floc water in a centrifuge tube Centrifuge at 4000rpm for 10 minutes, then remove the supernatant, and the average moisture content of the sludge flocs left at the end is 79.3%, which basically meets the municipal treatment requirements of reducing the moisture content to 80% before sludge disposal. Direct landfill or other treatment.

[0018] The brine or seawater used in this embodiment has the concentration of salt ions as shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com