Glass door body

A glass and door body technology, applied in the field of door body structure, can solve problems such as high manufacturing cost and difficult process control, and achieve the effects of reducing processing procedures, simplifying processing procedures, and reducing process losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

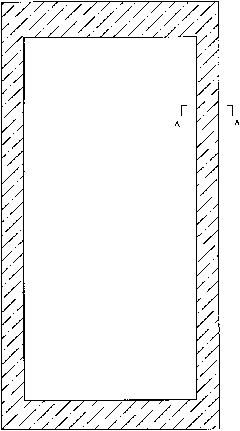

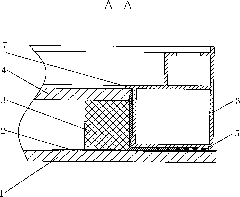

[0017] see Figure 1~2 , the glass door body of the present invention includes a front glass 1, a rear glass 4, and a door frame 6, and a desiccant 3 is sandwiched between the front glass 1 and the rear glass 4 and is adjacent to the door frame 6, and is composed of the front glass 1, the rear glass 4, and the door frame 6 The enclosed space is filled with inert gas, and the desiccant 3 absorbs the residual moisture in the enclosed space to prevent condensation on the glass surface. See figure 2 , the front glass 1 is wider than the rear glass 4, the door frame 6 is bonded to the back inside of the front glass 1, the door frame 6 is provided with a limit rib 7, and the edge of the rear glass 4 leans against the limit rib 7, and the door frame 6 Adhesive 5 is coated on both sides of the inner side of the front glass 1, the back inner periphery of the door frame 6 and the front glass 1, the outer surface of the desiccant 3, and the wall thickness side of the rear glass 4 are b...

Embodiment approach 2

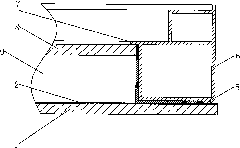

[0019] See image 3 , the glass door body is composed of front glass 1, inner door panel and door frame 6 to form the frame of the door body, and between the front glass 1 and the inner door panel is a foam insulation layer 9. The inboard of front glass 1 is an opaque shoe coating 2, and shoe coating 2 has covered the whole outer glass plate, and beautiful patterns, decorative patterns are arranged on shoe coating. The inner door panel is a plastic plate 8, and the limit ribs 7 on the door frame 6 are fixedly installed, and the inner side surfaces of the door frame 6 are coated with adhesive 5, so that the door frame 6 is connected to the back inner periphery of the front glass 1 and the inner door panel. The wall thickness side of plastic plate 8 is bonded together, front glass, rear inner plate, door frame are pasted and fixed, constitute a kind of glass door body, can be used as the door body of refrigerator, disinfection cupboard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com