Electric control system and control method for automatic flaw detection of steel pipes

An electrical control system and electrical control technology, applied to electrical program control, program control in sequence/logic controllers, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problem of less functions, more control components, and poor performance. Stability and other issues, to achieve the effect of powerful functions, simple system and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

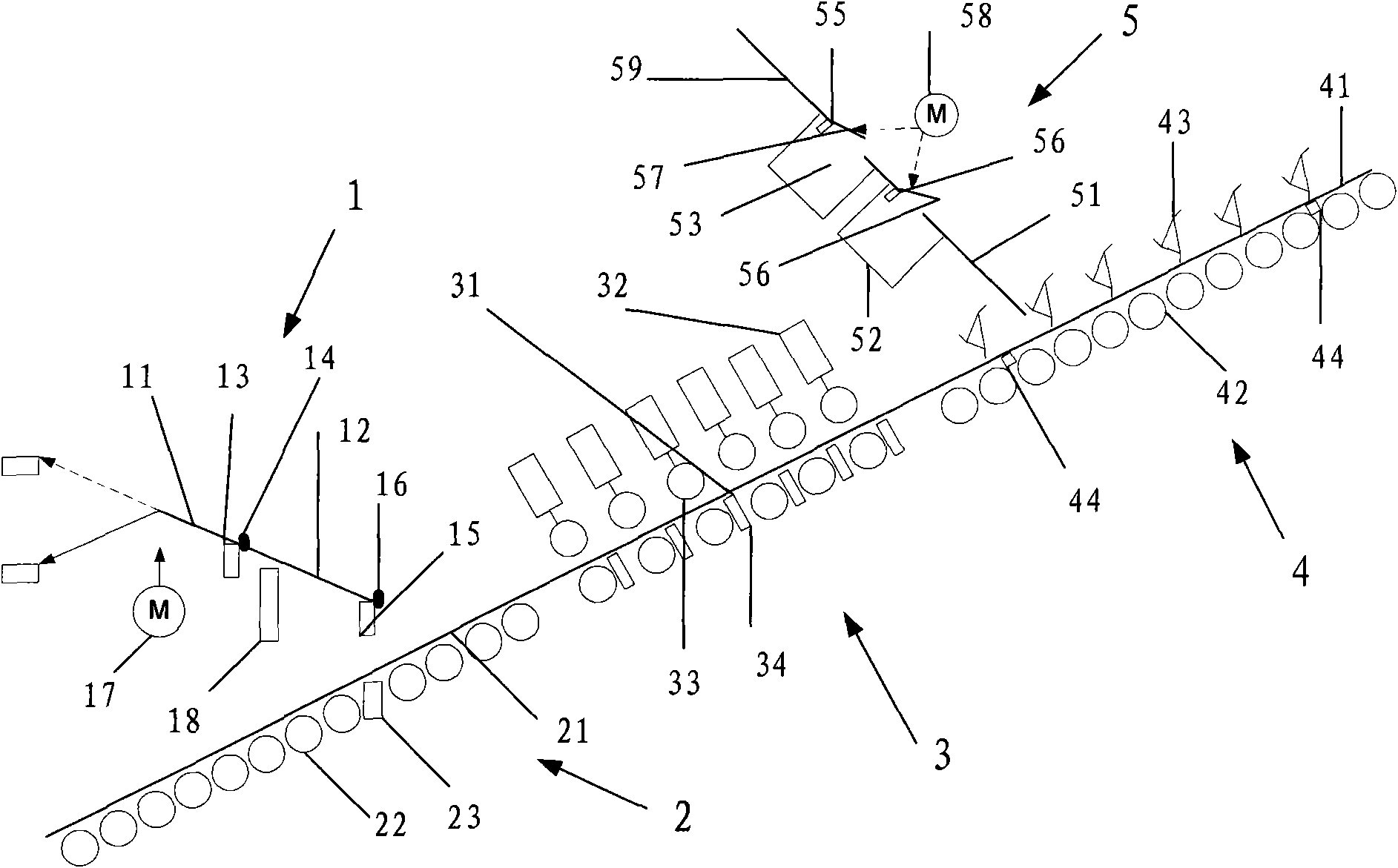

[0027] See figure 1 , The conventional automatic flaw detection equipment for steel pipes includes the material lifting part 1, the feeding part 2, the forced feeding part 3, the feeding part 4 and the material storage part 5. Among them,

[0028] The lifting part 1 includes a sorting track 11 and a lower rail 12 connected to the end of the sorting track 11, a first baffle plate 14 arranged at the end of the sorting track 11 and controlled by a topping solenoid valve 13, and At the tail end of the lower rail 12, the second baffle plate 16 is controlled by another ejector solenoid valve 15, the material lifting motor 17 provided on the material handling rail 11, and the material lifting proximity sensor 18 provided on the lower rail 12;

[0029] The feeding part 2 includes a feeding roller table 21 connected to the end of the lower rail 12 in the middle, twelve feeding roller table motors 22 for driving the feeding roller table 21 to rotate, and one installed on the feeding roller ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com