High-power LED phase-change cooling device

A phase-change cooling, high-power technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of difficult and reliable cooling of high-power LEDs, unfavorable marketization of high-power LEDs, and complex capillary structures. Low cost, strong practicability, good heat dissipation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] When a phase change material changes from one state to another, it needs to absorb or release heat from the environment, which can realize heat storage and release, and can achieve the purpose of temperature control. When the liquid state changes into the gaseous state, a large amount of heat is absorbed, and when the gaseous state condenses into a liquid state, heat is released. At the same time, the phase change process is generally an isothermal or nearly isothermal process. Using the characteristics of phase change materials, small The environment is temperature controlled and can be reused many times.

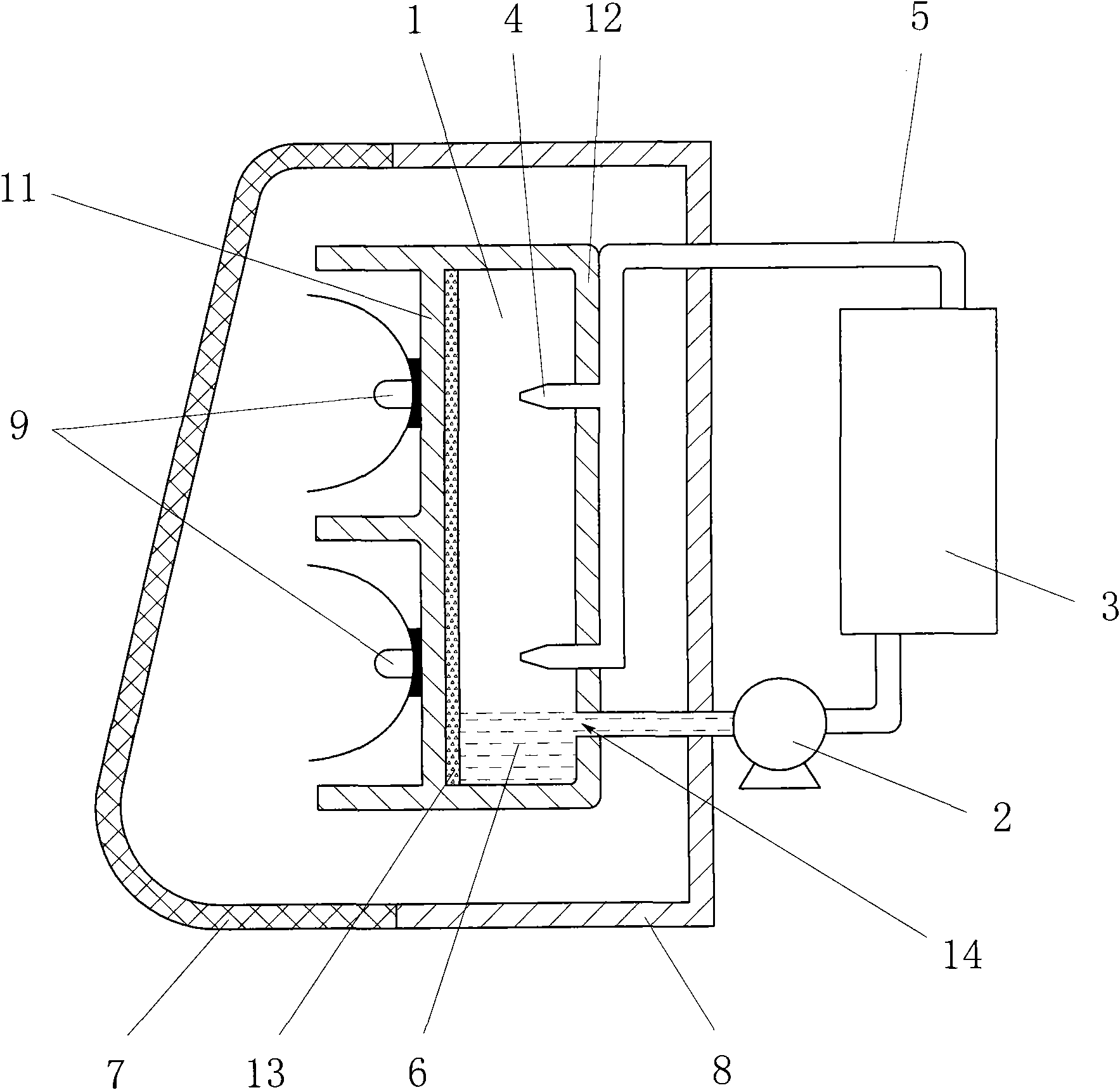

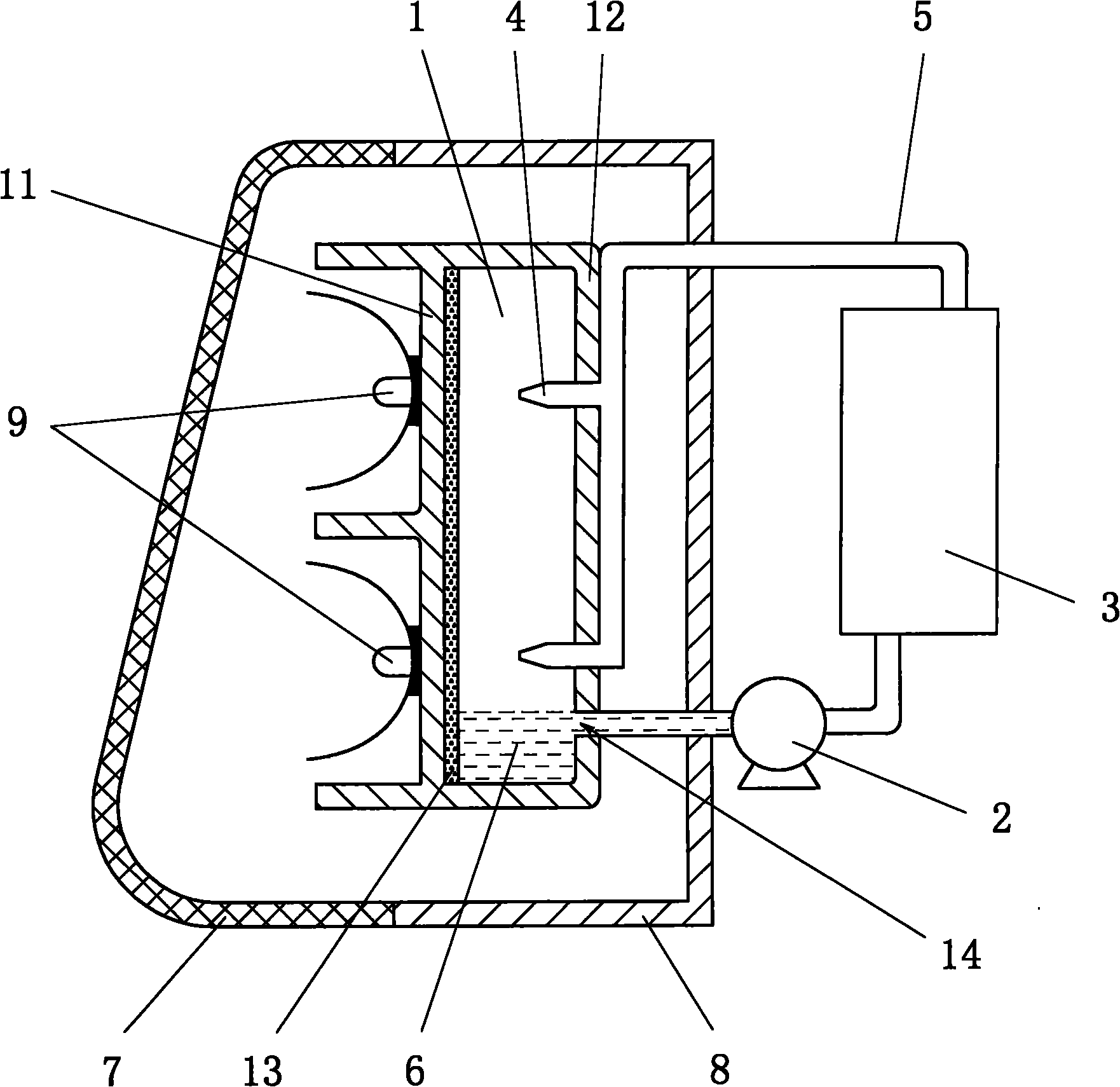

[0016] See figure 1 The high-power LED has a transparent lampshade 7 arranged on the front of the LED lamp 9 and a rear cover 8 connected to the transparent lampshade 7 and is located at the rear of the LED lamp 9. The phase change cooling device of the high-power LED has a transparent lampshade 7 and The evaporation chamber 1 in the rear cover 8, the nozzle 4 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com