Multistage sloping plate water treatment device

A technology of water treatment device and water distribution device, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as difficult removal of small particles, difference in flow velocity, and clogging of inclined plates , to achieve the effect of reduced particle content and good water discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

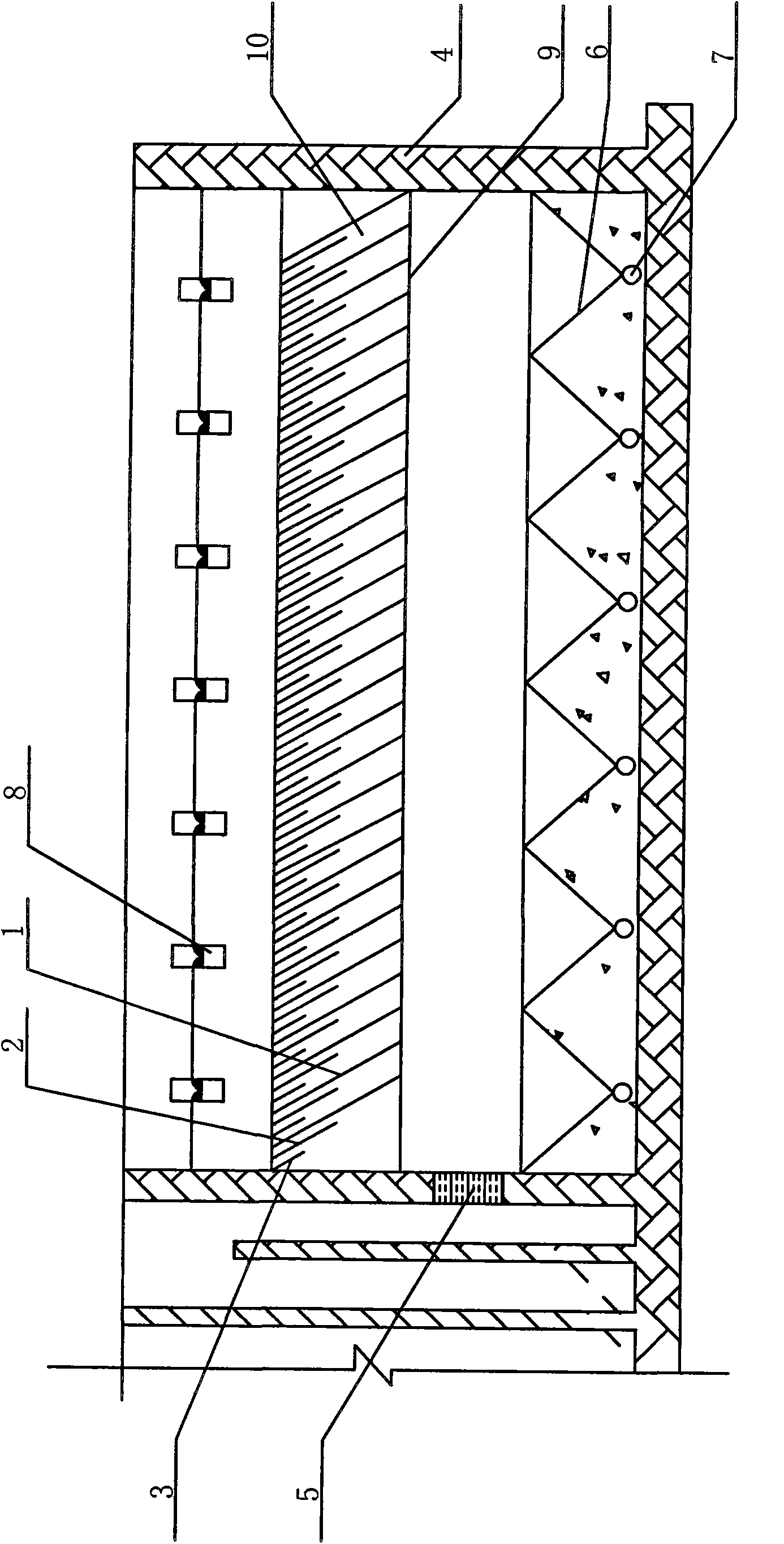

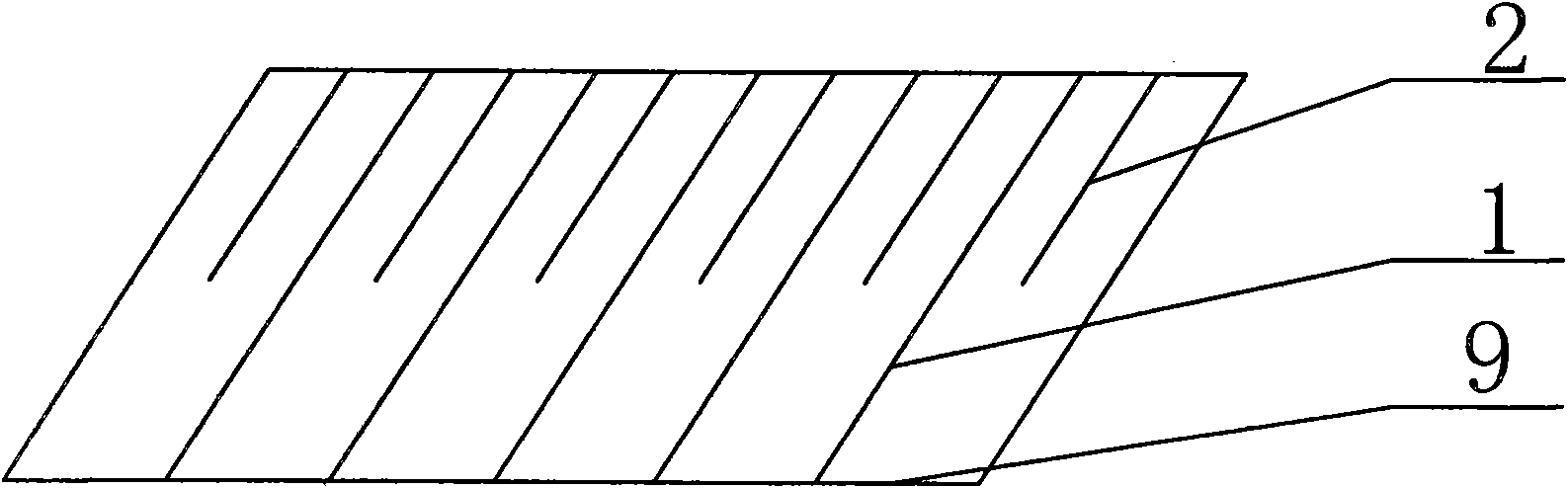

[0015] Such as figure 1 and 2 As shown, the multi-stage inclined plate water treatment device includes a sedimentation tank 4, an inclined plate group 10, a sedimentation bucket 6, a sludge discharge pipe 7, a water distribution device 5 and a plurality of water collection tanks 8, and the inclined plate group is placed in the sedimentation tank 4 to sink Above the mud bucket 6, the water collection tank 8 is placed above the inclined plate group 10, the mud discharge pipe 7 is arranged at the bottom of the mud sinking bucket 6, the water distribution device 5 is arranged on the side wall of the sedimentation tank 4 below the inclined plate group 10, and the inclined plate group 10 includes a plurality of inclined plates and steel bars 9 for fixing the inclined plates. The inclined plate group 10 is fixed between the left and right side walls of the sedimentation tank 4 through the steel bars 9. The inclined plate group 10 is composed of the long inclined plate 1 and the fixed...

Embodiment 2

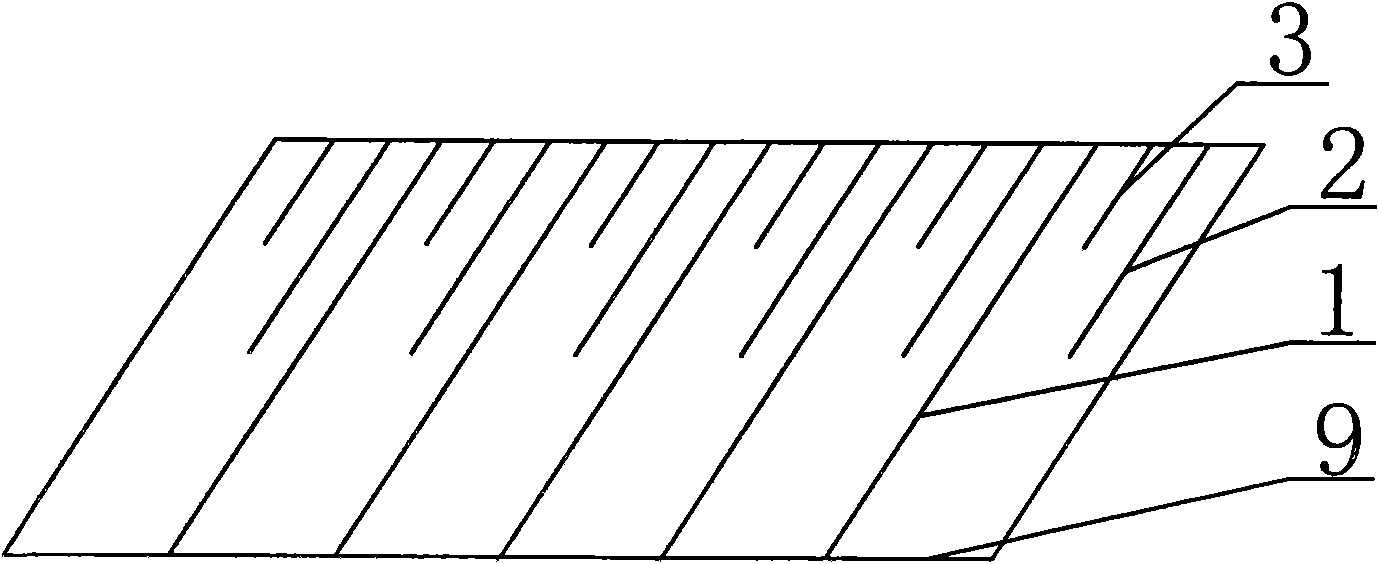

[0017] Such as figure 1 and 3 As shown, more than 10 sloping plate groups are composed of units formed by sequentially arranging short slanting plates 3 , medium-length sloping plates 2 and long sloping plates 1 fixed on the upper part of sloping plate group 10 at equal intervals. All the other structures are with embodiment 1.

Embodiment 3

[0019] Such as figure 1 and 4 As shown, the sloping plate group 10 is composed of a unit formed by a plurality of medium-length sloping plates 2 fixed at equal intervals on the upper part of the sloping plate group 10 and a large number of medium-length sloping plates 2 fixed at the lower part of the sloping plate group 10 at equal intervals. , the boundary of each unit is separated by long sloping plates 1 equally spaced from the upper and lower sets of medium-length sloping plates 2 . All the other structures are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com