Combined type polyester reaction tower

A reaction tower and combined technology, applied in the field of reaction devices, can solve problems such as complex equipment structure and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

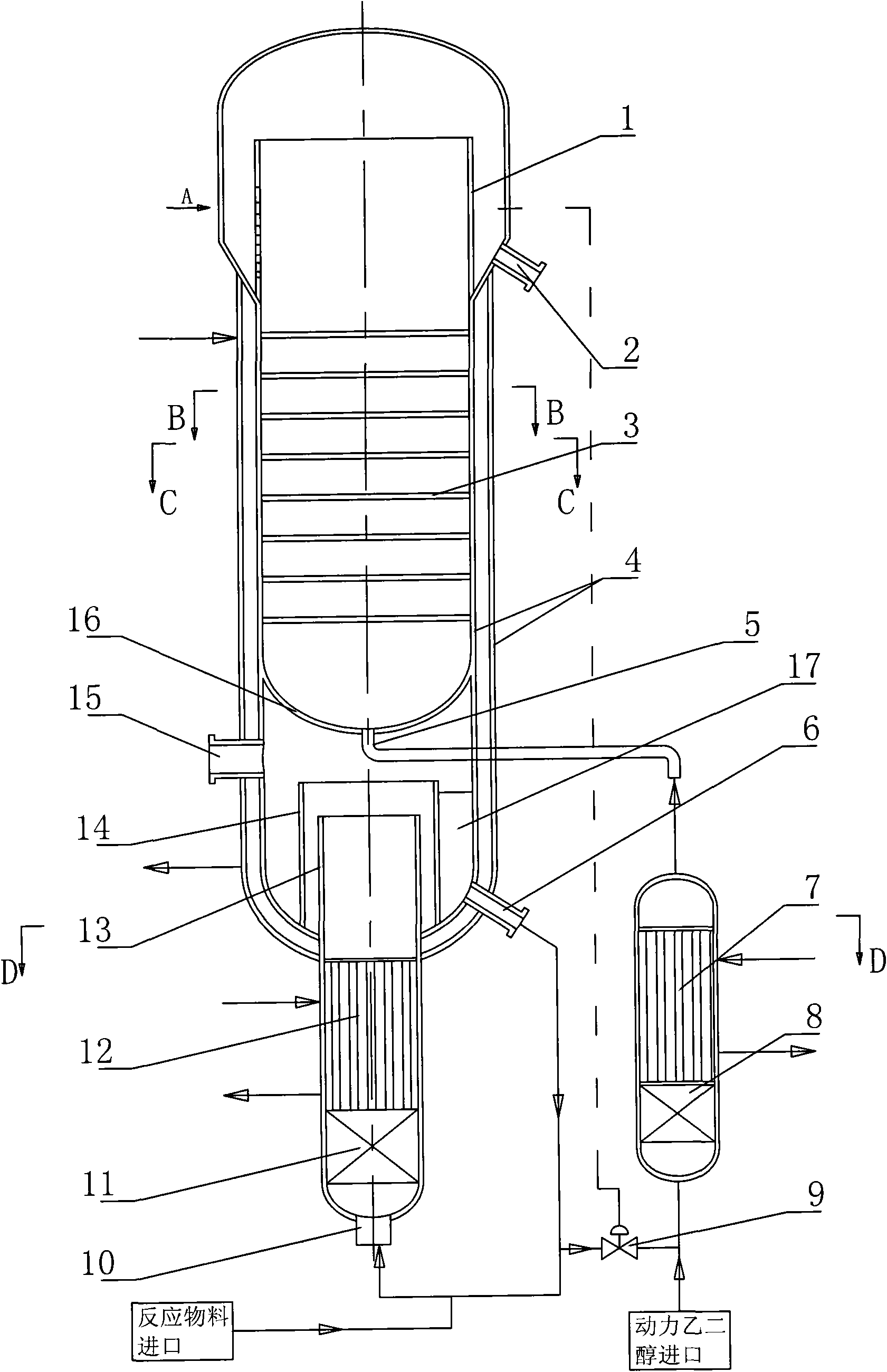

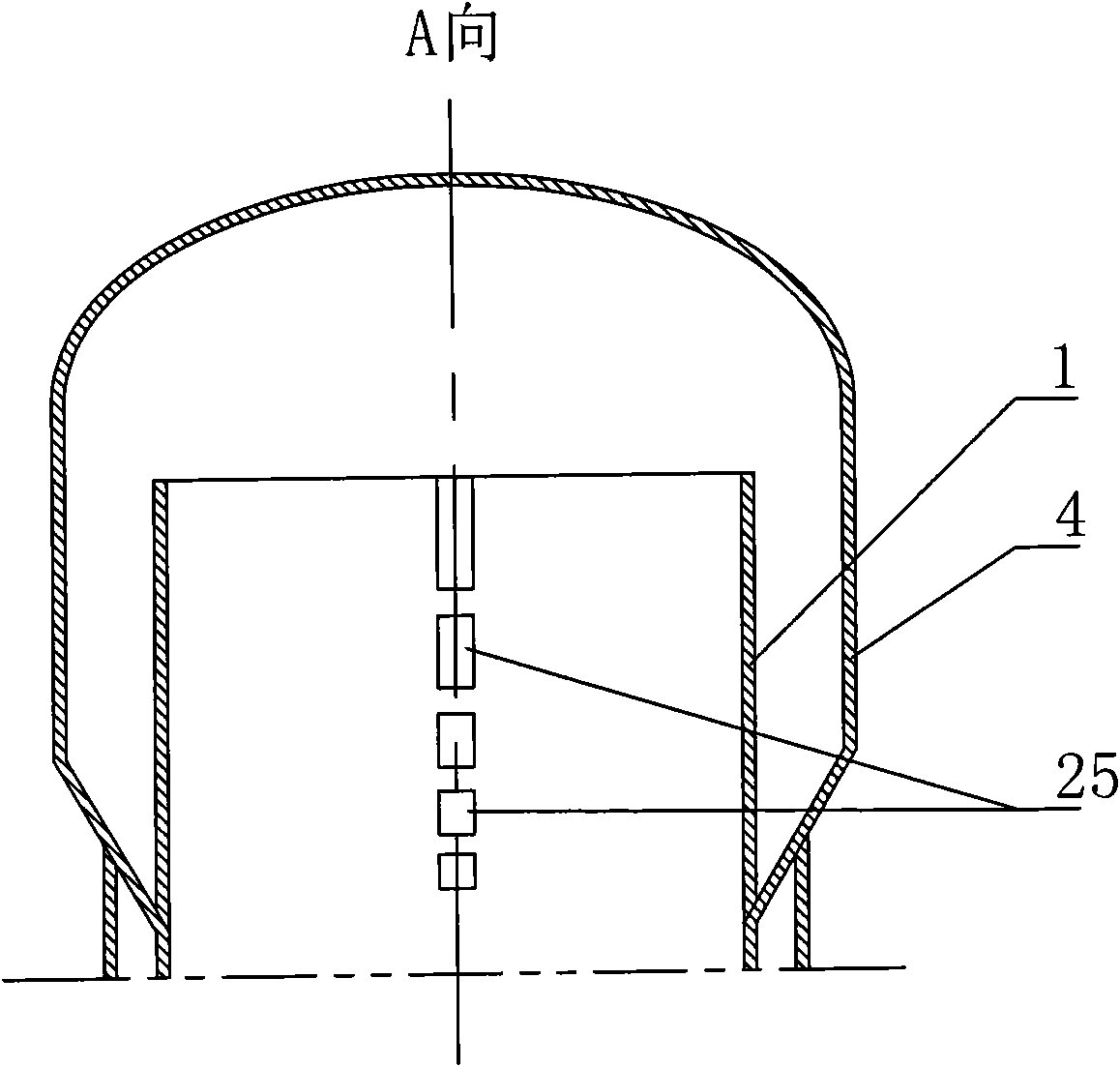

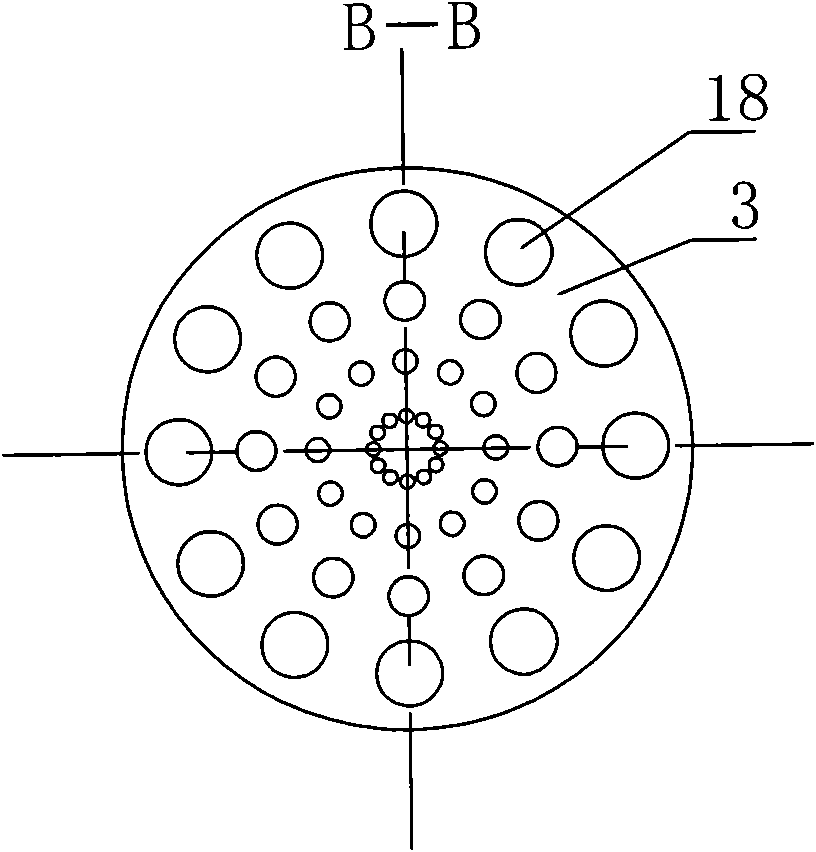

[0019] Such as Figure 1-5 As shown, it is a combined polyester reaction tower, and its structure mainly includes a closed vertical shell 4. The vertical shell 4 can be a double-layer shell with a jacket, and the inside of the jacket can be heated by a heating medium. The vertical housing 4 is divided into the upper polycondensation section housing and the lower esterification section housing through the partition plate 16 in the vertical housing 4; several flow-blocking distribution plates 3 are horizontally provided in the polycondensation section housing; The upper part of the body is provided with a liquid outlet 2, and the lower part of the polycondensation section housing is provided with a liquid inlet 5; the lower part of the esterification section housing is provided with a main heater 12, and the outlet on the upper part of the main heater 12 is connected to the lower part of the esterification section housing. The lower side of the shell of the esterification sectio...

Embodiment 2

[0022] Such as Image 6 , the difference with embodiment 1 is that: the polycondensation section shell top is provided with ethylene glycol vapor phase outlet 22, and the baffle plate top is provided with conical umbrella cap 23, and the baffle plate 1 of umbrella cap 23 lower sides is provided with several Strip hole 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com