Automatic control device for use in Czochralski crystal growth

An automatic control device and crystal growth technology, which is applied in crystal growth, single crystal growth, and self-melt pulling method, etc., can solve the problems of out-of-control growth, unstable quality, unfavorable production scale, etc., to reduce errors and stabilize products Quality, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

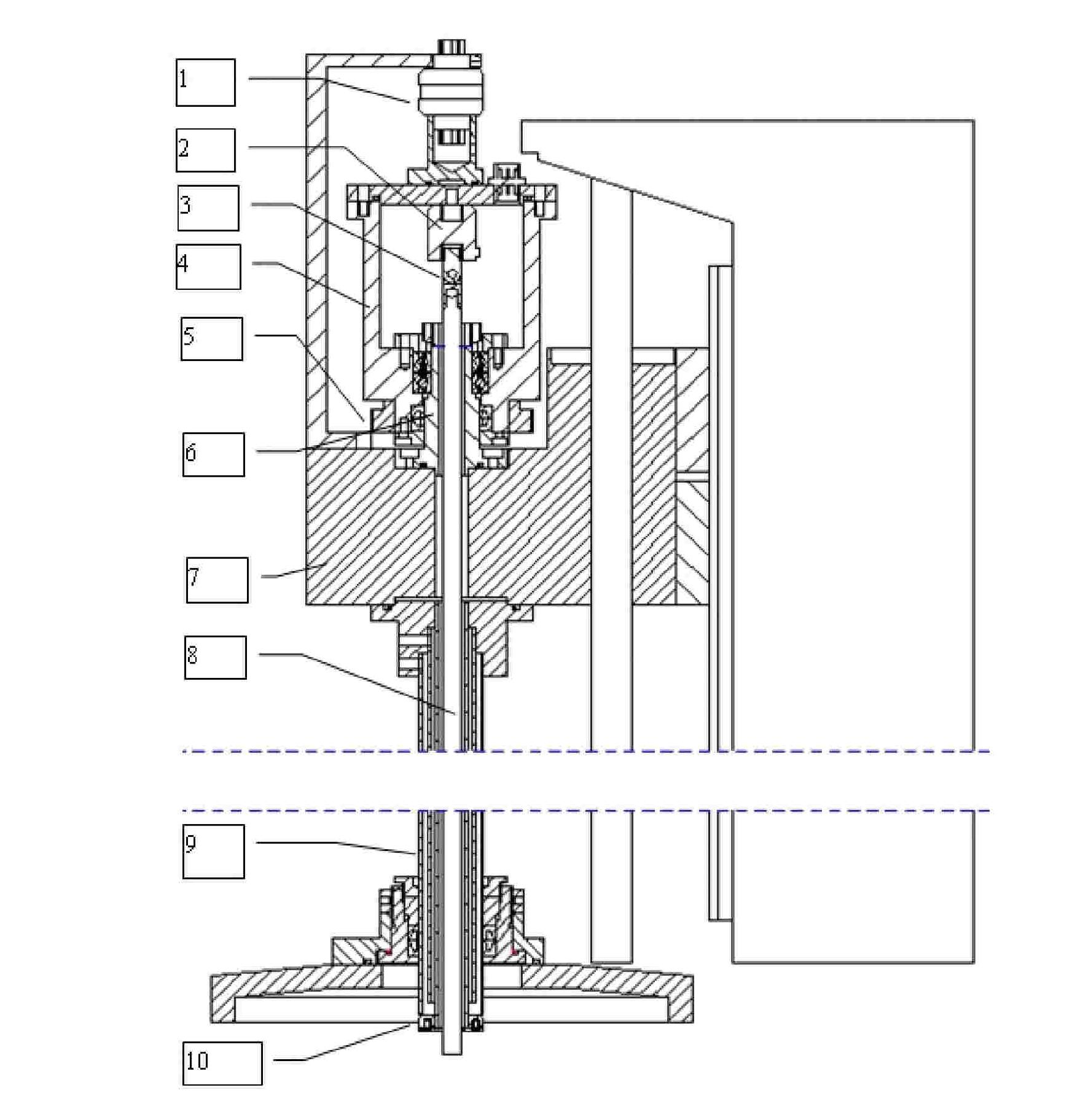

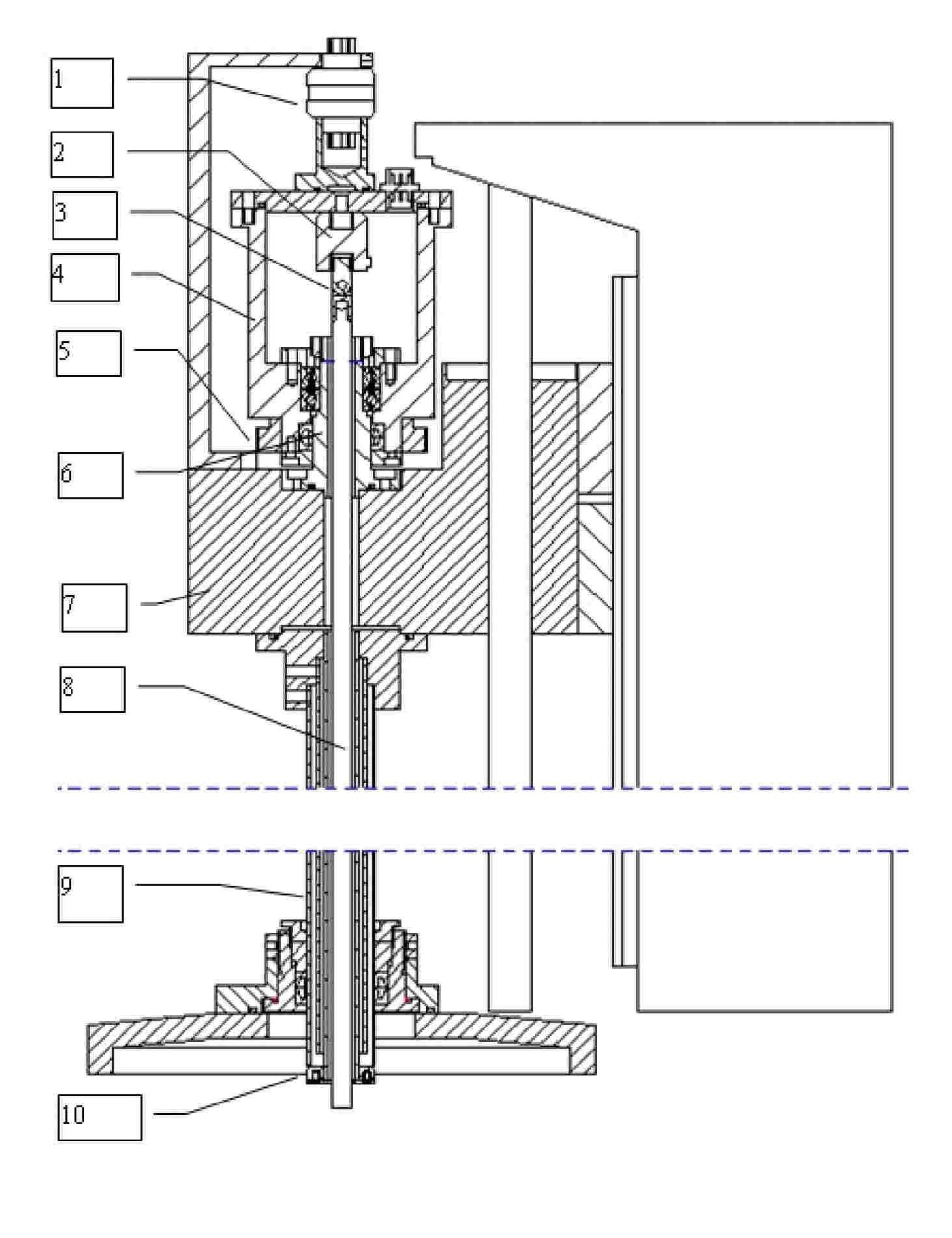

[0013] Such as figure 1 The shown pulling method crystal growth automatic control device includes a support base 7, a pulley 5, a seed rod 8 passing through the support base, a temperature controller (not shown), a weighing chamber 4, a weight sensor 2, Bearing seat 6, sliding contactor 1, cooling water jacket 9, seed rod positioning plate 10, connecting piece 3; the weighing chamber is located on the upper part of the supporting seat, and the bearing seat is fixedly connected between the bottom wall of the weighing chamber and the supporting seat , the outer wall of the weighing chamber is connected to the pulley; the sliding contactor is fixedly connected to the upper end of the weighing chamber, the weight sensor is fixedly connected to the upper part of the weighing chamber, and the signal line of the weight sensor passes through the sliding contactor and the controller (not shown in the figure) Out), the output end of the controller is connected to the temperature control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com